Precursor with double-layer structure for lithium ion battery, positive electrode material and preparation method

A lithium-ion battery, double-layer structure technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of reducing material tap density, unfavorable material compaction density, etc., to improve stability and improve cycle stability. performance, and the effect of increasing the specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

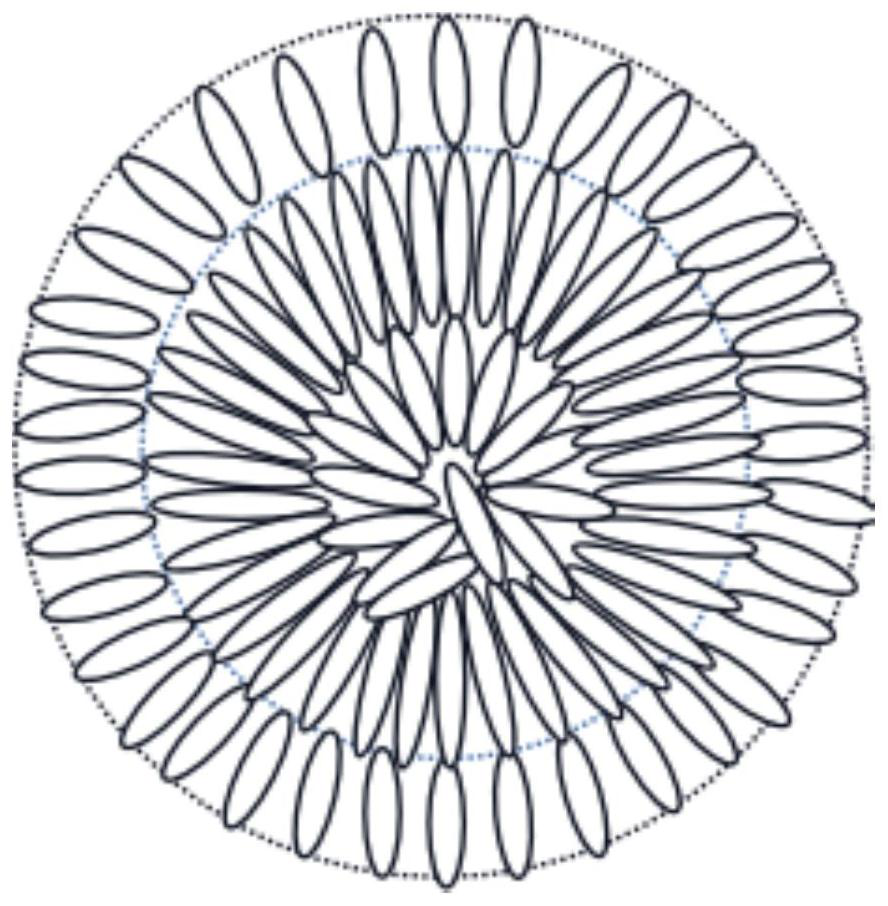

[0026] The preparation method of the precursor for the lithium-ion battery of double-layer structure comprises the following steps:

[0027] (1) Mix soluble nickel salt, soluble cobalt salt, soluble manganese salt, and soluble M salt corresponding to doping element M according to the ratio of molar ratio Ni: Co: Mn: M to x: y: (1-x-y-a): a , to obtain the first mixed salt solution, wherein, 0.3<x<1, 0<y<0.7, 0<a≤0.05, and the doping element M is one or more of Mg, Ti, Y. The sum of the concentrations of nickel ions, cobalt ions, manganese ions and M ions in the first mixed salt solution is 1mol / L˜3mol / L. Soluble nickel salt is one or more of nickel sulfate, nickel chloride and nickel nitrate; soluble cobalt salt is one or more of cobalt sulfate, cobalt chloride and cobalt nitrate; soluble manganese salt is manganese sulfate, chlorine One or more of manganese chloride and manganese nitrate; the soluble M salt is one or more of sulfate, chloride, and nitrate.

[0028] (2) Mix ...

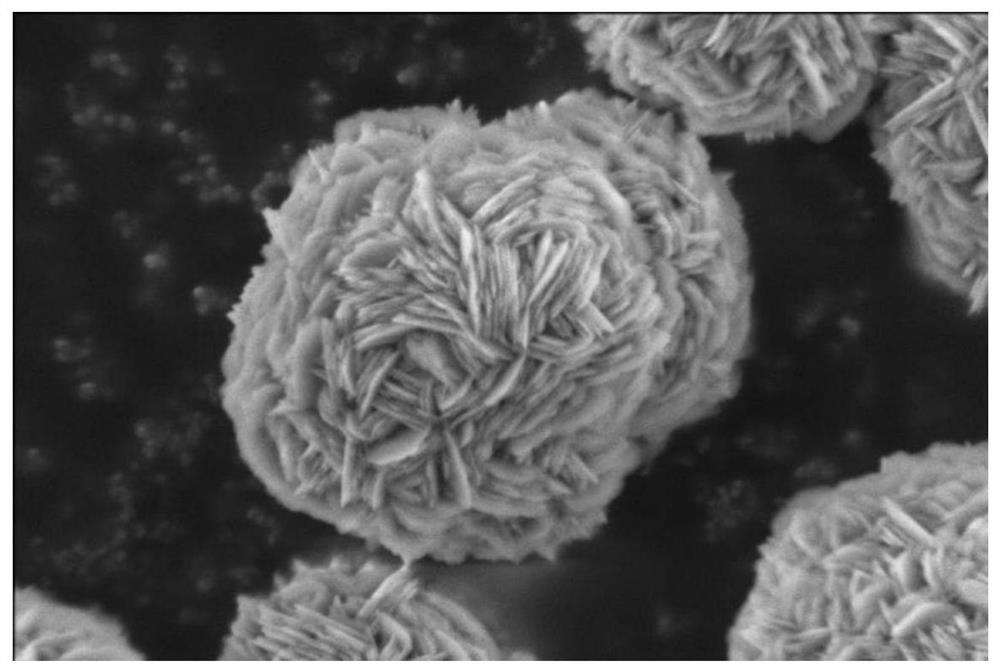

Embodiment 1

[0034] Mix the mixed solution of nickel sulfate and nickel nitrate, the mixed solution of cobalt sulfate and cobalt nitrate, the mixed solution of manganese nitrate and manganese sulfate, magnesium sulfate, Fully mixed with the mixed solution of magnesium nitrate to prepare the first mixed salt solution with a total concentration of metal ions of 3 mol / L.

[0035] Fully mix nickel sulfate, cobalt sulfate, manganese sulfate and zirconium sulfate solutions according to the ratio of molar ratio Ni:Co:Mn:Zr of 0.8:0.1:0.05:0.05 to make the second mixture with a total concentration of metal ions of 3mol / L saline solution.

[0036] Under the protection of an inert gas, the first mixed salt solution, the sodium hydroxide solution with a concentration of 5mol / L, and the ammonia water with a concentration of 8mol / L were respectively added to the reaction kettle containing the bottom liquid through a metering pump. The flow rate that the solution is added into the reaction kettle conta...

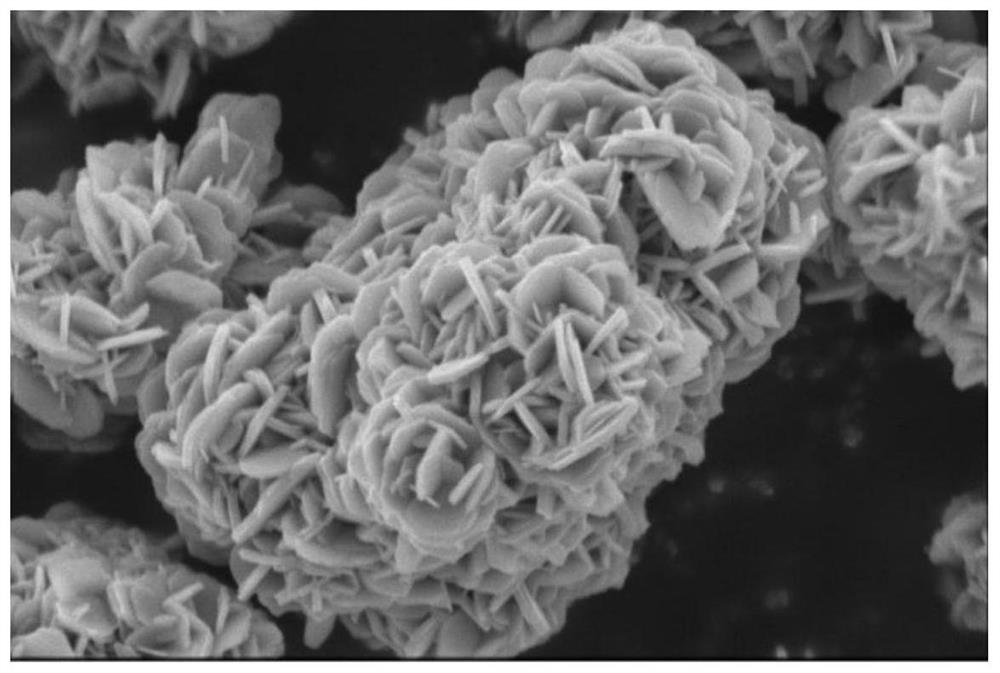

Embodiment 2

[0041] Fully mix nickel sulfate, cobalt sulfate, manganese sulfate, and titanium sulfate solutions according to the molar ratio Ni: Co: Mn: Ti of 0.9: 0.03: 0.02: 0.05 to make the first solution with a total concentration of metal ions of 1mol / L. Mix the salt solution.

[0042] Mix the mixed solution of nickel sulfate and nickel nitrate, the mixed solution of cobalt sulfate and cobalt nitrate, manganese nitrate and manganese sulfate according to the ratio of molar ratio Ni: Co: Mn: W: Al 0.9: 0.03: 0.02: 0.025: 0.025 solution, a mixed solution of tungsten sulfate and tungsten nitrate, and a mixed solution of aluminum sulfate and aluminum nitrate are thoroughly mixed to prepare a second mixed salt solution with a total concentration of metal ions of 1 mol / L.

[0043] Under the protection of an inert gas, the first mixed salt solution, the sodium hydroxide solution with a concentration of 3mol / L, and the ammonia water with a concentration of 6mol / L were respectively added to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com