A device and method for testing the contact stress of freshly mixed concrete

A technology of contact stress and concrete, applied in the direction of measuring devices, measuring force, instruments, etc., to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

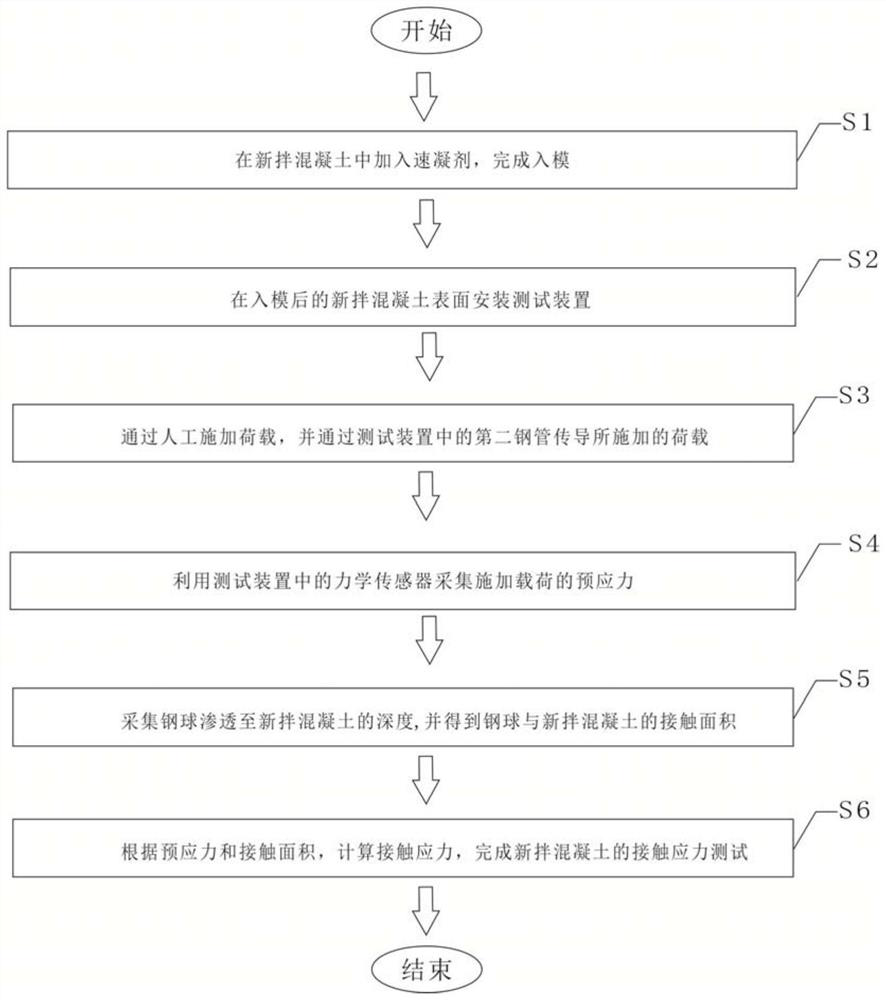

[0049] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0050] Such as figure 1 As shown, the present invention provides a device for testing the contact stress of fresh concrete, including a steel ball 1, a mechanical sensor 2, a steel plate 3, a first LVDT4, a second LVDT5, a first steel pipe 6 and a second steel pipe 7;

[0051] The steel ball 1 is movably arranged on the surface of fresh concrete, and the steel ball 1 and the mechanical sensor 2 are fixedly connected through the first steel pipe 6; the second steel pipe 7 is fixedly arranged above the mechanical sensor 2; the first LVDT4 and the second LVDT5 are respectively fixed It is arranged on both sides of the mechanical sensor 2; the two ends of the steel plate 3 are respectively fixedly connected to the first LVDT4 and the second LVDT5;

[0052] The steel ball 1 is used to simulate coarse aggregate; the second steel pipe 7 is used to transmit the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com