Surrounding rock collaborative control system and construction method of traffic tunnel

A technology of collaborative control and construction method, applied in the direction of tunnel, tunnel lining, earthwork drilling and mining, etc., to achieve the effect of preventing large deformation of surrounding rock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

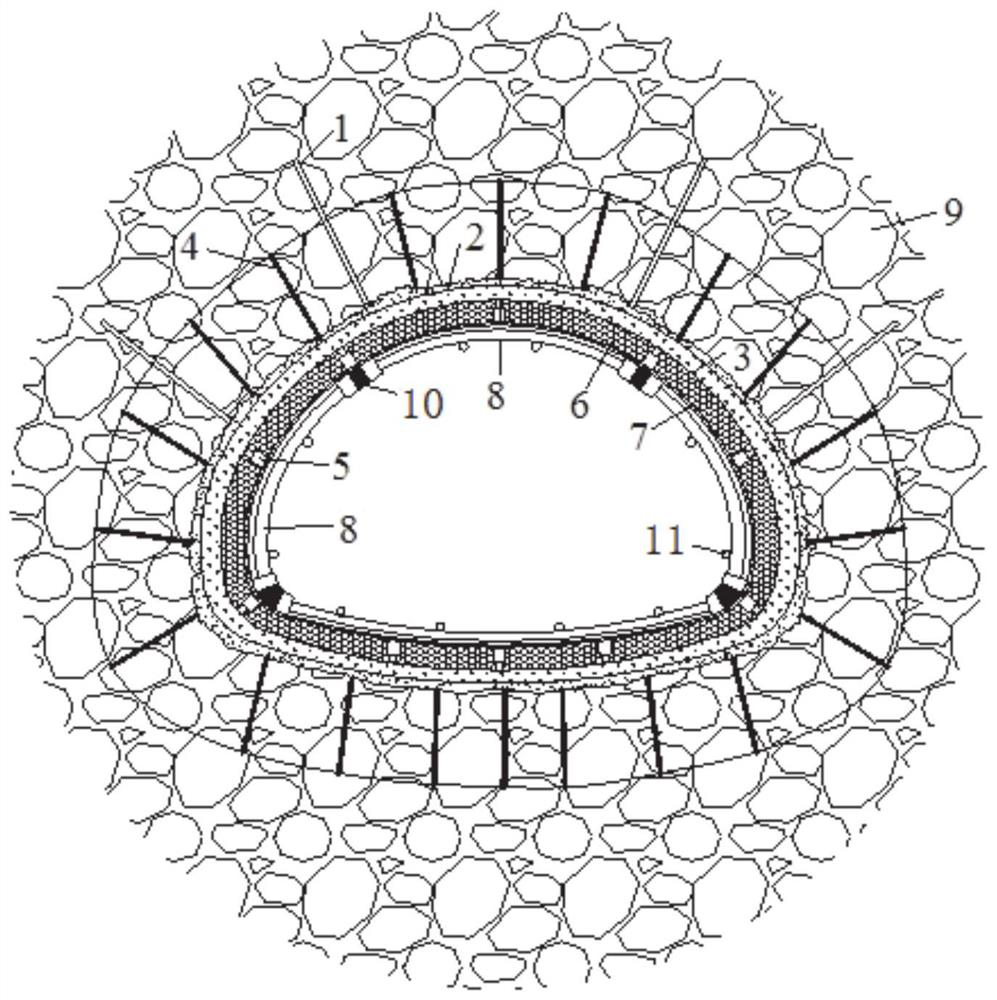

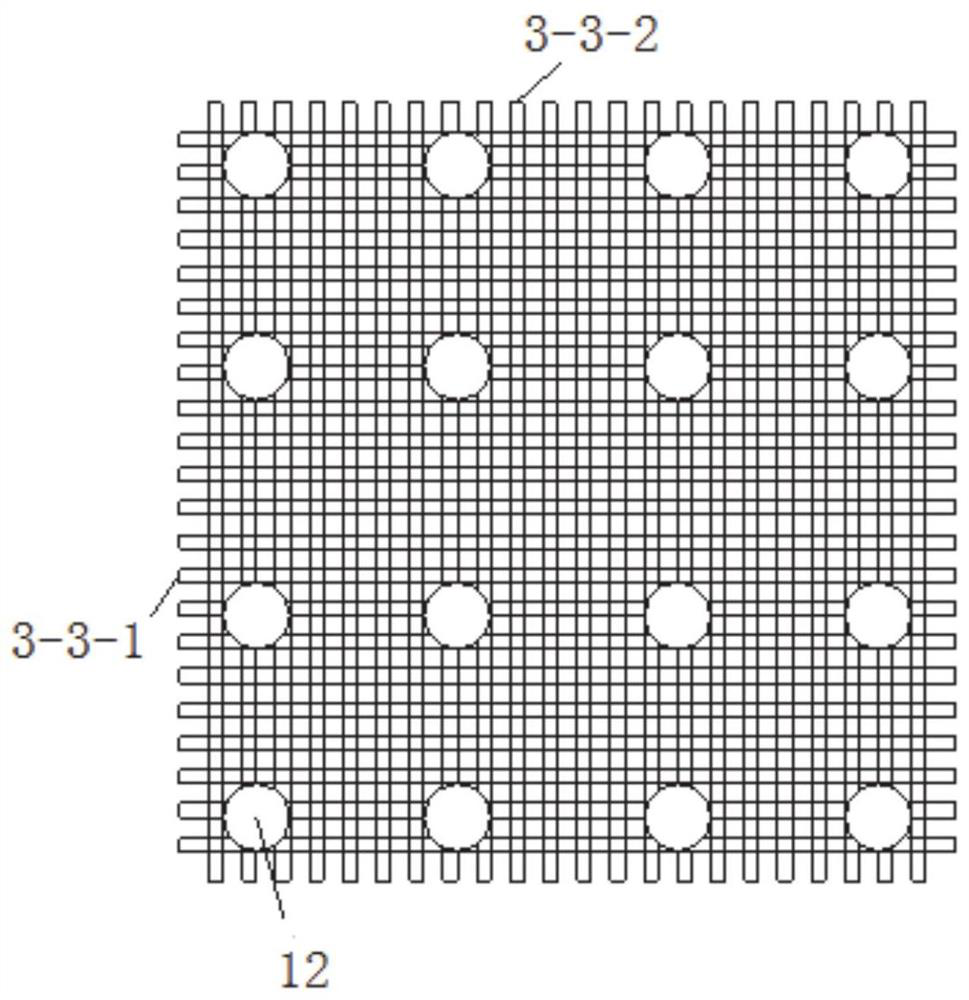

[0045] This embodiment discloses a construction method of a traffic tunnel surrounding rock collaborative control system. According to the large deformation parameters of the surrounding rock obtained in the previous period and the geological data obtained in the previous geological exploration, a numerical model is established through finite element software, and a reasonable maximum value is determined through numerical calculation. Optimal support parameters, including the diameter, length, row spacing, prestress size, rigid arch section size, arch spacing, longitudinal connection ring distance, etc. Energy layer, rigid guard plate layer, rigid arch and anchors. Construction includes the following specific steps:

[0046] Step 1: After the tunnel is excavated, use a pressure relief drilling rig to drill a hole 1 on the surface of the surrounding rock 9. After drilling, use a directional blasting device to blast the deep rock formation, which can effectively relieve the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com