Cleaning device

A technology for cleaning devices and cleaning furnaces, which is applied to descaling devices, cleaning methods and utensils, cleaning methods using tools, etc., to achieve the effects of improving safety, good cleaning effect, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

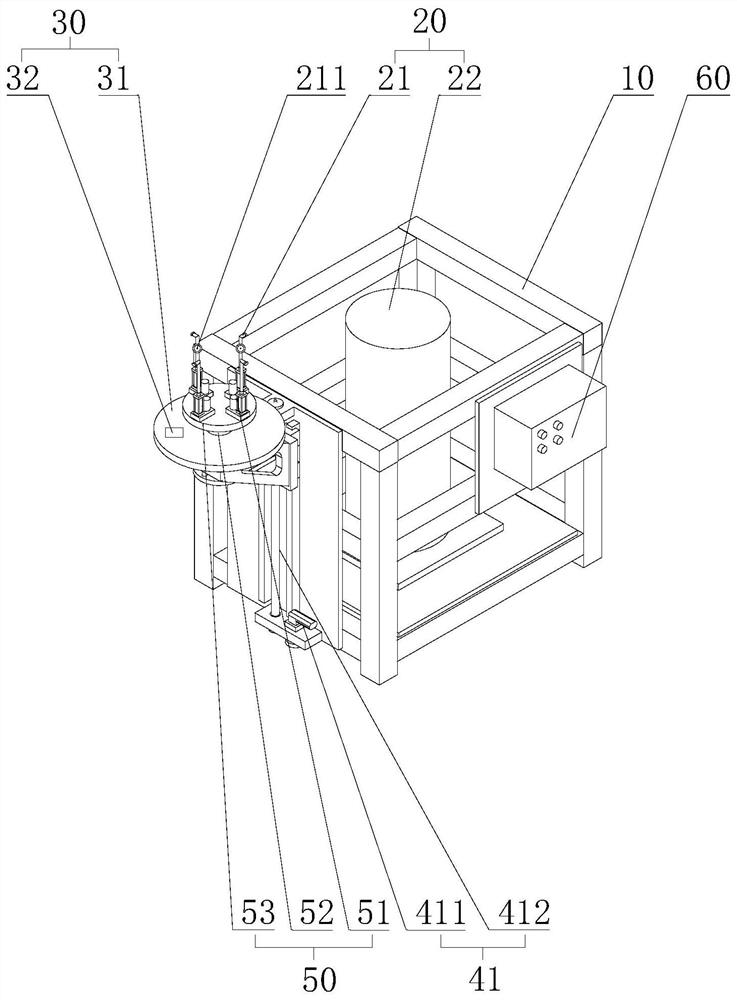

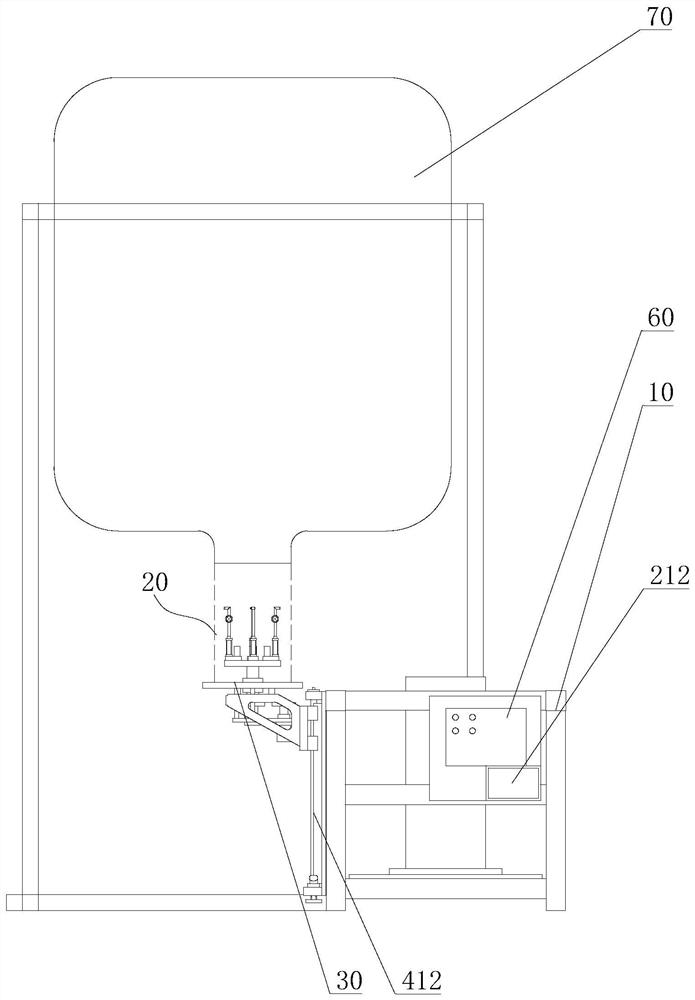

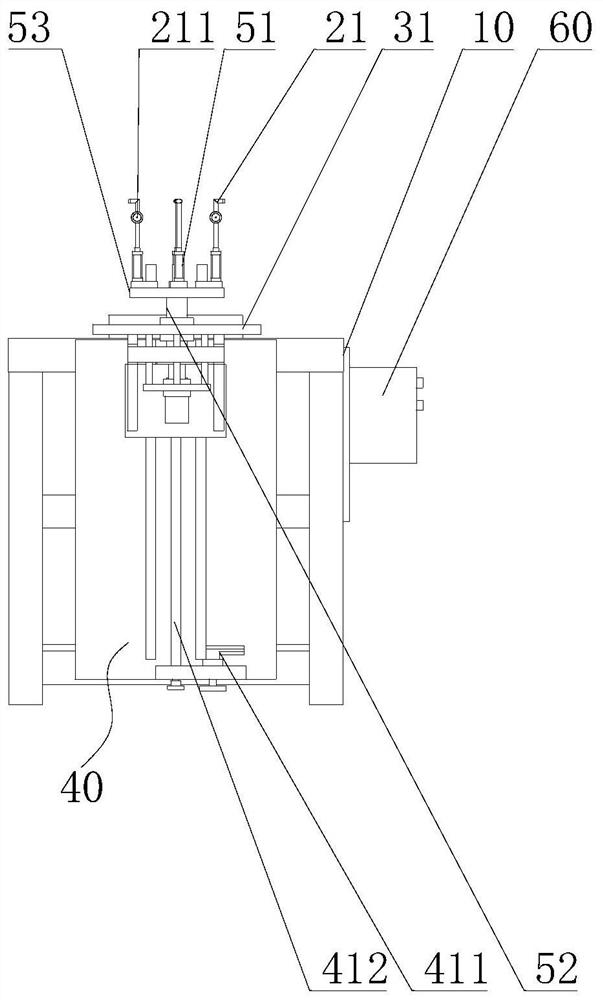

Image

Examples

Embodiment approach 1

[0049] Embodiment 1, the gasket protrudes to the furnace mouth and has an interference fit with the inner wall of the furnace chamber (not shown).

Embodiment approach 2

[0050] Embodiment 2, the gasket is clamped between the package cover 31 and the end surface of the furnace mouth (not shown).

[0051] Extend the sealing gasket into the furnace mouth so that the sealing gasket has an interference fit with the inner wall of the furnace cavity, or clamp the sealing gasket between the packaging cover 31 and the end face of the furnace mouth, which can further seal the gap between the packaging cover 31 and the furnace mouth The gap improves the sealing effect. In addition, since the dust-absorbing member 21 is arranged on the sealing unit 30, when the cleaning unit 20 cleans the oven cavity, even if the packaging cover 31 vibrates slightly, the setting of the sealing pad buffers the vibration, improving the stability of the cleaning device, and at the same time Improve dynamic sealing effect.

[0052] like figure 1 As shown, in a preferred embodiment, the cleaning device includes a second driving unit 50 , the second driving unit 50 is fixed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com