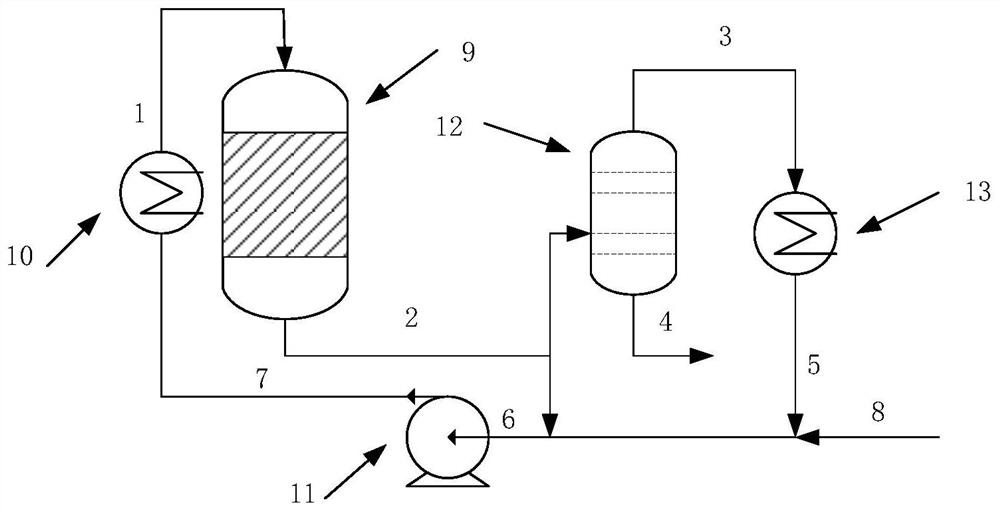

Activity control method of in-situ decoking material of aromatic hydrocarbon deolefination catalyst and application thereof

A control method and catalyst technology, which are applied in the direction of catalyst regeneration/reactivation, molecular sieve catalyst, chemical instruments and methods, etc., can solve the problems of large amount of hazardous waste of catalyst, long regeneration period, large activity loss, etc., and achieve low cost and regeneration. Simple, high utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] According to patent CN102218338A embodiment 5 prepared catalyst 100.0g containing Zr, Cu, Al, Ce, Y molecular sieve / alumina, bromine index is 950mgBr / 100g reformed oil, in 8h -1 , Under 1.9MPa, the reaction was evaluated at temperatures of 160, 170, 180, and 195°C, and the evaluation time when the outlet reached the bromine index of 150mg / 100g was 70, 90, 120, and 150 hours, respectively. Cut off the raw material for evaluation. Then, after nitrogen purging at 60°C for 10 hours, use 30-60°C pentane and hexane mixture (1:1) 500g, 3.0Mpa, 10h -1 Wash down for 24 hours, then heat up to 90°C, wherein 20% of the material enters the subsequent distillation tower, and 1% of the coke-containing material is circulated back to the decoking system for 20 hours, and the coke content of the material entering and leaving the reactor is 1.5% ( weight content) and 1.7% (weight content) and then enter the process of removing soluble coke matter: feed nitrogen and purge at 90° C. for 20...

Embodiment 2

[0063] Catalyst (containing La, Ce, P, Mg and USY molecular sieve) 100.0g prepared by CN102029180A embodiment 6 is the reformed oil of 950mgBr / 100g in bromine index, in 8h -1 , Under 1.9MPa, the reaction was evaluated at temperatures of 160, 170, 180, and 195°C, and when the bromine index at the outlet reached 150mg / 100g, the evaluation time was 58, 65, 67, and 72 hours, respectively. In-situ decoking under the same conditions as in Example 1 above, and then the same reaction conditions were evaluated to obtain time evaluation times of 58, 64, 65, and 68 hours, respectively.

Embodiment 3

[0065] The catalyst 100.0g prepared by patent CN102218338A embodiment 5 is the reformed oil whose bromine index is 950mgBr / 100g, in 8h -1 , Under 1.9MPa, the reaction was evaluated at a temperature of 170°C, and different evaluation times were evaluated when the bromine index at the outlet reached 150mg / 100g. The evaluation times were 80, 100, 130, and 180 hours to obtain different catalysts. Each catalyst after the evaluation is passed through petroleum ether at normal temperature, at a space velocity of 1h -1 , Decoking under the pressure 1.0MPa, the circulation rate was 50% at the beginning, and the circulation rate was 90% after 20 hours, and was 100% after another 2 hours, and stopped petroleum ether in 1 hour (the coke content difference of the material entering and leaving the reactor was 0.1%), then feed nitrogen, and stop nitrogen after feeding at normal temperature for 10 hours. Each revived catalyst in 8h -1 , 1.9MPa, under the reformed oil whose bromine index is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bromine index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com