Coating method of sugar-coated tablets

A sugar-coated tablet and coating technology, which is applied in sugar-coated pills, pharmaceutical formulations, medical preparations with inactive ingredients, etc., can solve the problems of unqualified products, easy fading, high-polluting tablets, etc., so as to reduce dosage and consumption, reduce Environmental pollution, the effect of reducing the coating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

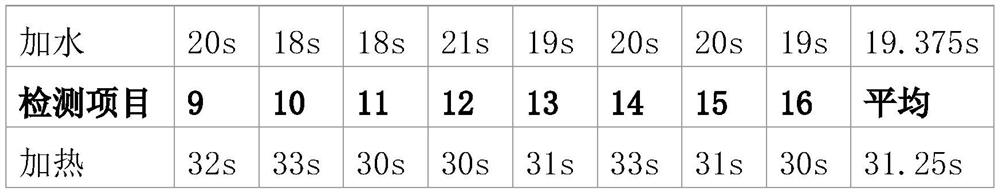

Image

Examples

Embodiment 1

[0038] The first step, the package isolation layer:

[0039] Put the tablets into the coating pan, heat the material to 47°C, then add gelatin at 31ml / kg for plain tablets, so that the gelatin is evenly attached to the surface of each tablet, and then add 22g / kg of talcum powder for plain tablets to make the talc The powder can be evenly attached to the surface of each tablet. Finally, after all the tablets are scattered, blow hot air on the tablets in the coating pan for 2 minutes, so that each tablet is fully dried and covered with a layer of isolation layer, repeat the above operation 2 times until each tablet is completely wrapped with no nudity.

[0040] The amount of the plain tablet is the ratio of the material to the pure tablet (tablet without coating). The amount of gelatin is 25ml / kg for the plain tablet, which means 25ml of gelatin for 1kg of the plain tablet. The purpose of the isolation layer is to isolate the drug from the outside world, and prevent the moistur...

Embodiment 2

[0059] The first step, the package isolation layer:

[0060] Put the tablet into the coating pan, heat the material to 50°C, then add gelatin according to the amount of 40ml / kg of plain tablet, so that the gelatin is evenly attached to the surface of each tablet, and then add 25g / kg of talcum powder in the amount of plain tablet, so that Talcum powder can be evenly attached to the surface of each tablet. Finally, after all the tablets are scattered, blow hot air on the tablets in the coating pan for 4 minutes to make each tablet fully dry and wrap a layer of isolation layer. Repeat the above steps. Operate 3 times.

[0061] The second step is to pack the powder coating layer:

[0062] After controlling the temperature of the material at 45°C, add the mixed slurry according to the amount of 30ml / kg of plain tablets, so that the mixed slurry can be evenly attached to the surface of each tablet, and add 13g / kg of talcum powder in the amount of plain tablets, and also make the ta...

Embodiment 3

[0077] The first step, the package isolation layer:

[0078] Put the tablets into the coating pan, heat the material to 54°C, then add gelatin at 43ml / kg for plain tablets, so that the gelatin is evenly attached to the surface of each tablet, and then add 28g / kg of talcum powder for plain tablets, so that Talcum powder can be evenly attached to the surface of each tablet. Finally, after all the tablets are scattered, blow hot air on the tablets in the coating pan for 4 minutes to make each tablet fully dry and wrap a layer of isolation layer. Repeat the above steps. Operate 4 times.

[0079] The second step is to pack the powder coating layer:

[0080] After controlling the temperature of the material at 48°C, add the mixed slurry according to the amount of 35ml / kg of the plain tablet, so that the mixed slurry can be evenly attached to the surface of each tablet, and add an appropriate amount of talcum powder in the amount of 17g / kg of the plain tablet, and also make the talc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com