Anti-scratch PU bright floor paint and preparation method thereof

A technology for anti-scratch and floor paint, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems that the scratch resistance of the paint film cannot be effectively solved, affect the appearance of the wooden floor, and increase the amount of paint, etc. Achieve the effect of improving scratch resistance, good adhesion, and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of above-mentioned anti-scratch PU bright floor paint, it comprises the following steps of carrying out in sequence:

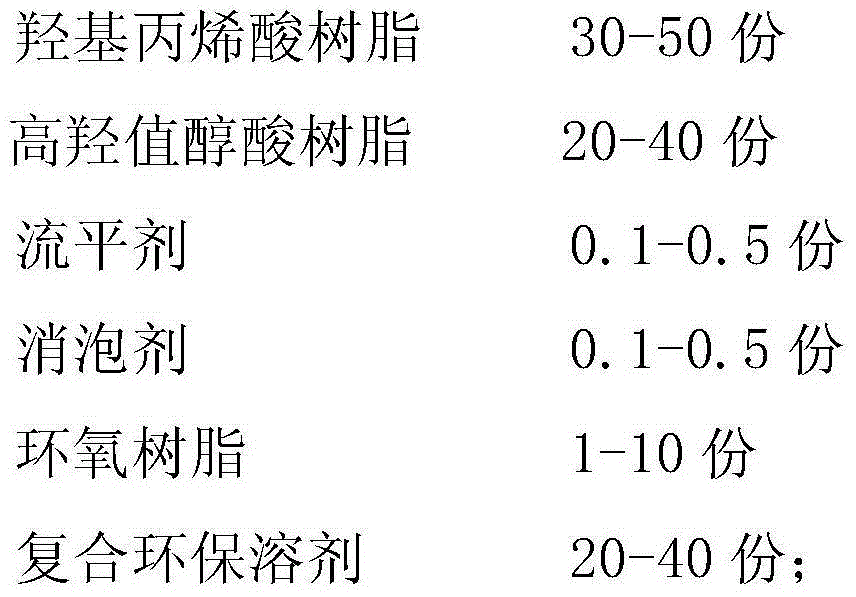

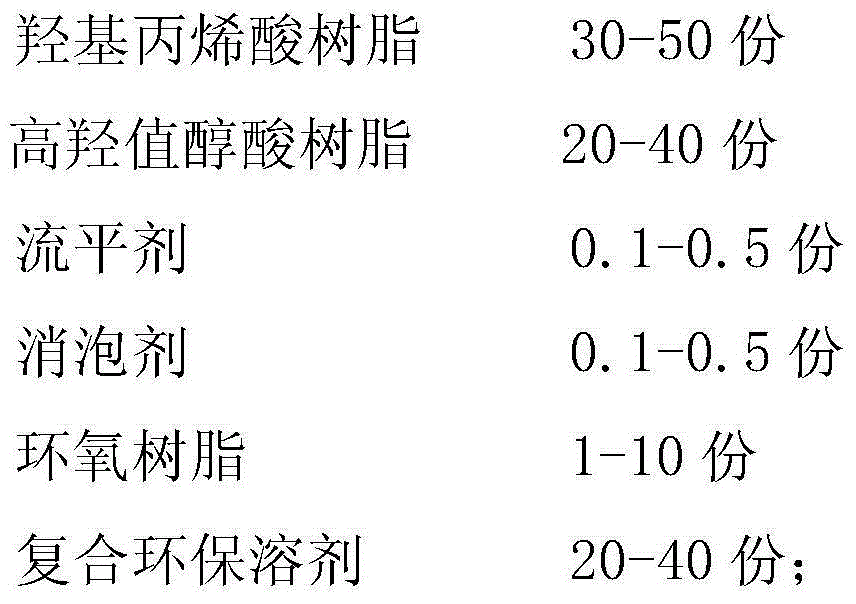

[0031] (1) The component A is prepared according to the following preparation method: 30-50 parts of hydroxy acrylic resin, 20-40 parts of high-hydroxy alkyd resin, 0.1-0.5 parts of leveling agent, 0.1-0.5 parts of defoamer, Add 1-10 parts of epoxy resin and 20-40 parts of composite environmental protection solvent into the container, disperse evenly at a low speed at a speed of 600-800r / min, filter through a 400-600 mesh filter and pack;

[0032] (2) The B component is prepared according to the following preparation method: add 10-40 parts of TDI-TMP, 10-30 parts of HDI trimer, 10-20 parts of moisture curing agent, and 30-50 parts of butyl acetate into another In the container, disperse evenly at a low speed at a speed of 600-800r / min, filter through a 400-600 mesh filter and pack.

[0033] The above-mentioned composite environm...

Embodiment 1

[0036] Embodiment 1 is a preferred embodiment:

[0037] Anti-scratch PU glossy floor paint, which is prepared from component A and component B in a weight ratio of 1:1: component A is made of the following raw materials in weight ratio:

[0038]

[0039] Component B is made from the following raw materials in weight ratio:

[0040]

[0041] The preparation method of above-mentioned anti-scratch PU bright floor paint, it comprises the following steps of carrying out in sequence:

[0042] (1) The component A is prepared according to the following preparation method: 40 parts of hydroxyacrylic resin, 26 parts of high-hydroxy alkyd resin, 0.2 part of leveling agent, 0.4 part of defoamer, 5 parts of epoxy resin, 28.4 parts Add the compound environmental protection solvent into the container, disperse at a low speed of 800r / min, filter it with a 600-mesh filter, and pack it;

[0043] (2) The B component is prepared according to the following preparation method: Add 30 parts ...

Embodiment 2

[0046] Embodiment 2 is a preferred embodiment:

[0047] Anti-scratch PU glossy floor paint, which is prepared from component A and component B in a weight ratio of 1:1: component A is made of the following raw materials in weight ratio:

[0048]

[0049]

[0050] Component B is made from the following raw materials in weight ratio:

[0051]

[0052] The preparation method of above-mentioned anti-scratch PU bright floor paint, it comprises the following steps of carrying out in sequence:

[0053] (1) The component A is prepared according to the following preparation method: 43 parts of hydroxyacrylic resin, 24 parts of high-hydroxy alkyd resin, 0.2 part of leveling agent, 0.4 part of defoamer, 4 parts of epoxy resin, 28.4 parts Add the compound environmental protection solvent into the container, after dispersing at a low speed of 600r / min, filter it with a 400-mesh filter and pack it;

[0054] (2) The B component is prepared according to the following preparation me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com