Low-voc polyurethane matte varnish and preparation method thereof

A polyurethane and matte technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of dry paint film, low solid content in construction, poor fullness, etc., and achieve high solid content in construction and plump paint film , the effect of reducing the number of coating layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0031] A low-VOC polyurethane glossy varnish, characterized in that: it is prepared from component A and component B in a weight ratio of 1:0.8-1.2;

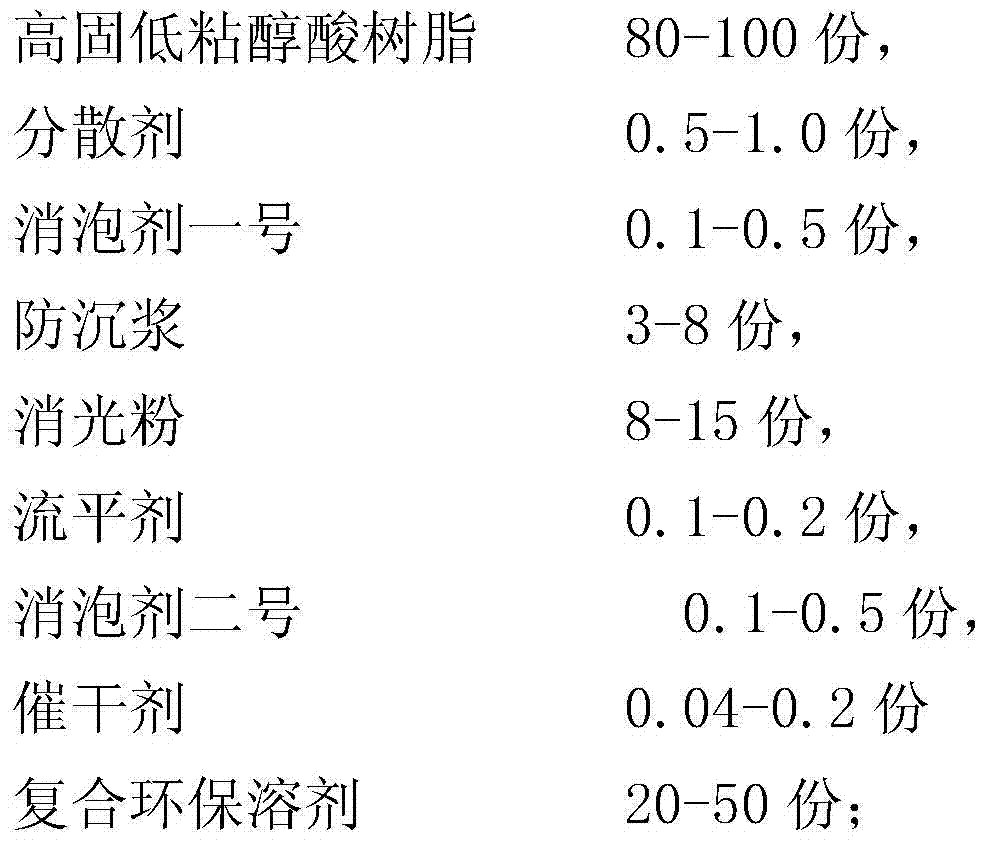

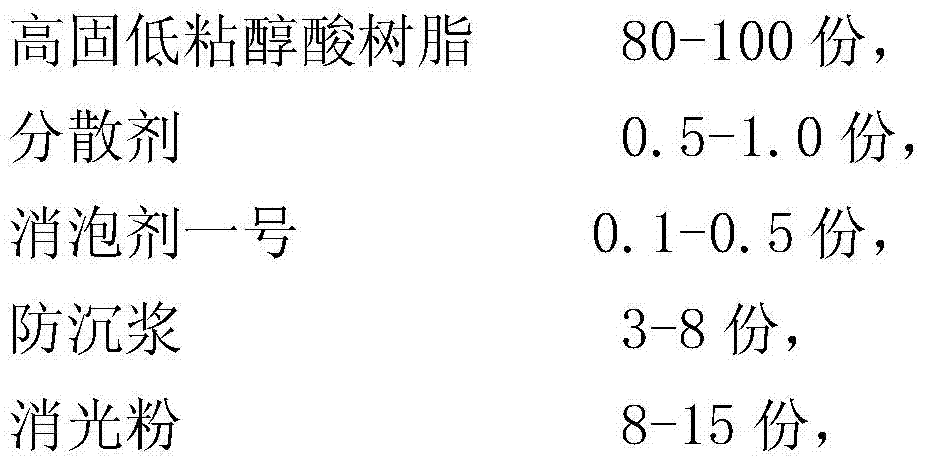

[0032] The first component is made from the raw materials of the following weight ratio:

[0033]

[0034]

[0035] The B component is made from the raw materials of the following weight ratio:

[0036] TDI trimer 50-70 parts,

[0037] HDI trimer 20-40 parts,

[0038] 15-30 parts of butyl acetate.

[0039] Further, the high-solid and low-viscosity alkyd resin is prepared from the following components in the following parts by weight ratio:

[0040]

[0041] The reflux solvent is one of xylene and toluene. The diluted solvent is one of xylene, butyl acetate and ethyl acetate.

[0042] The fatty acid is one of soybean oil fatty acid, castor oil fatty acid and octadecenoic acid. The No. 1 polyol is one or both of pentaerythritol or trimethylolpropane mixed in any proportion; the No. 2 polyol is one or both of neopent...

Embodiment 1

[0060] Add 24.77g of soybean oil fatty acid, 15.13g of pentaerythritol, 0.11g of hypophosphorous acid, and 4.13g of xylene into a four-neck flask with a stirring device in sequence, stir evenly, heat up, and heat up to 205-220 degrees in 1-2 hours, and keep warm for the reaction 1-2 hours, then cool down to below 190 degrees, add 5.26g neopentyl glycol, 5.77g diethylene glycol, 0.61g maleic anhydride, 27.79g phthalic anhydride, continue to heat up, at 200- React at 220°C until the acid value is less than 14mgKOH / g, viscosity 4-7S / div, 25°C, then cool down to below 150°C, add 16.43g of butyl acetate, stir evenly for 0.5 hours, and discharge.

Embodiment 2

[0062] Add 28.66g of soybean oil fatty acid, 14.99g of pentaerythritol, 0.14g of hypophosphorous acid, and 4g of xylene into a four-necked flask with a stirring device in sequence, stir evenly, heat up, and heat up to 205-220 degrees in 1-2 hours. -2 hours, then cool down to below 190 degrees, add 4.82g neopentyl glycol, 5.50g diethylene glycol, 26.89g phthalic anhydride, continue to heat up, react at 200-220 degrees, until the acid value is less than 14mgKOH / g, viscosity 4-7S / grid, 25 degrees, then lower the temperature to below 150 degrees, add 15g xylene, stir evenly for 0.5 hours, and discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com