Preparation method of high-performance DFB laser epitaxial wafer

An epitaxial wafer, high-performance technology, applied in the field of optical communication, can solve the problems of poor etching uniformity, low product yield, affecting the secondary epitaxial growth of products, etc., to achieve the effect of improving uniformity and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] This patent discloses a method for preparing a high-performance DFB laser epitaxial wafer, which specifically includes the following steps:

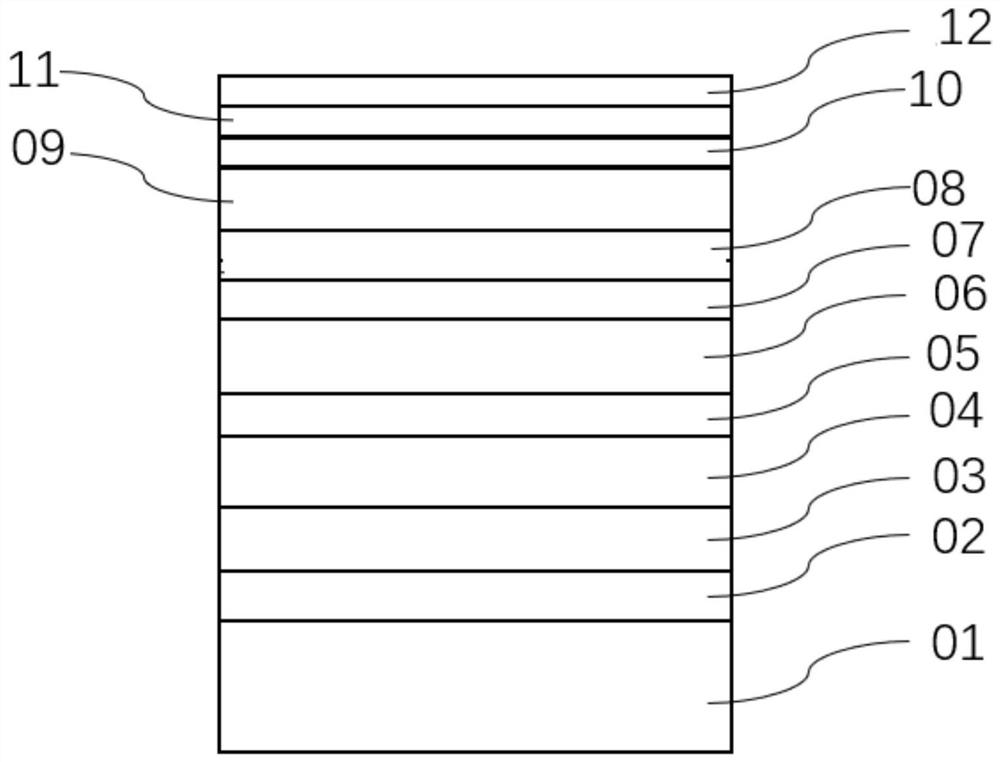

[0027] First as figure 1 As shown, put the InP substrate 01 into the MOCVD equipment, and deposit growth buffer, 02, confinement layer 03, lower waveguide layer 04, quantum well layer 05, upper waveguide layer 06, The upper confinement layer 07, the buffer layer 08, the etching barrier layer 09, the InP cladding layer 10, the grating layer 11, and the InP cap layer 12 form a primary epitaxial wafer structure, wherein the grating layer 11 is an InGaAsP grating layer.

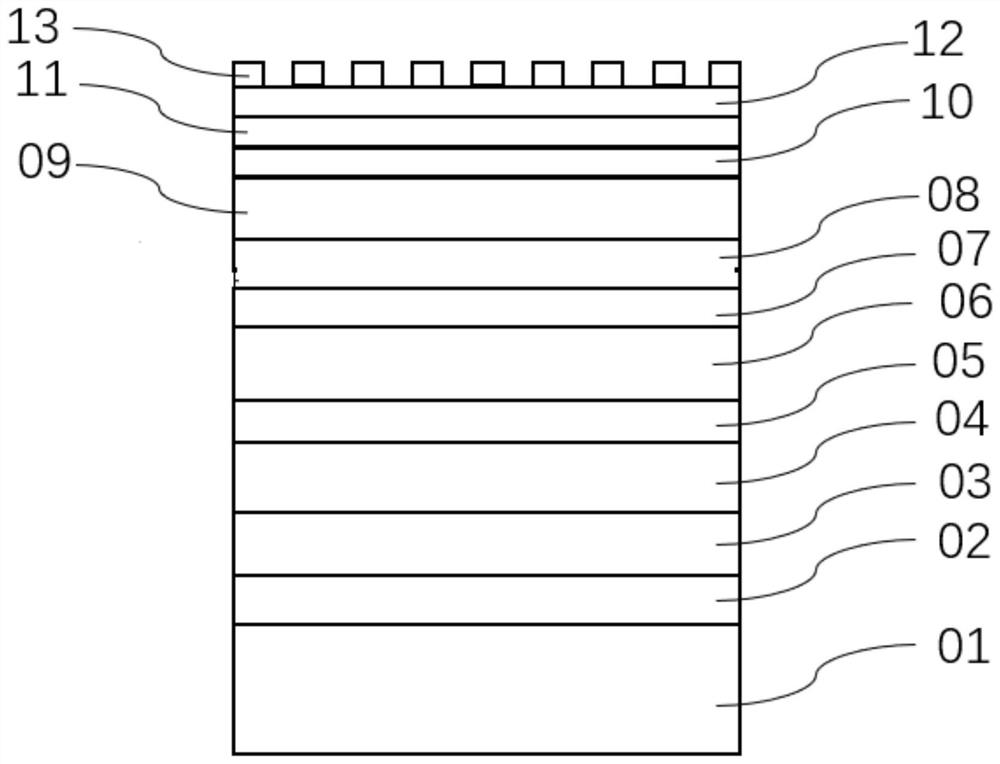

[0028] like figure 2 As shown, the epitaxial wafer is taken out from the MOCVD equipment, photoresist is spin-coated on the InP cap layer 12 of the epitaxial wafer, and a photoresist mask 13 is formed by holographic lithography.

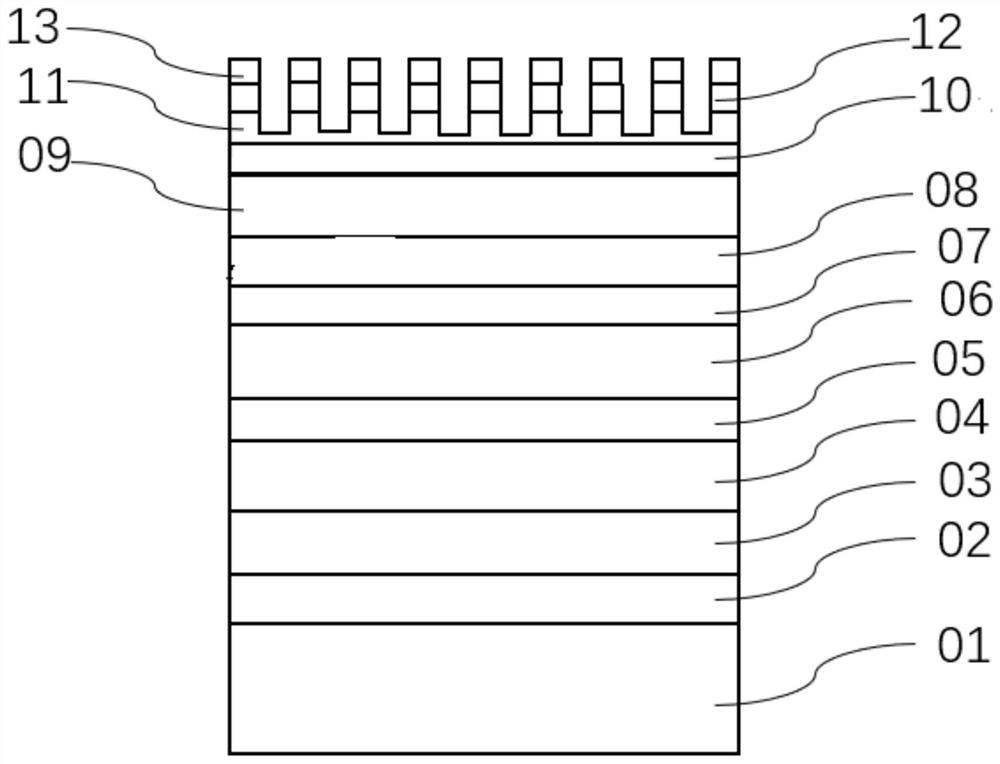

[0029] like image 3 As shown, the epitaxial wafer is etched with an etching solution, and the InP cap layer 12 and part of the InGaAs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com