Spent fuel post-treatment plant sample analysis method and system

A technology for sample analysis and spent fuel, which is applied in the direction of material analysis, material analysis, and material separation using wave/particle radiation. It can solve the problems of low analysis efficiency, poor safety, and low sample utilization, so as to avoid sample accumulation, Ease of management and reduction in sample volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

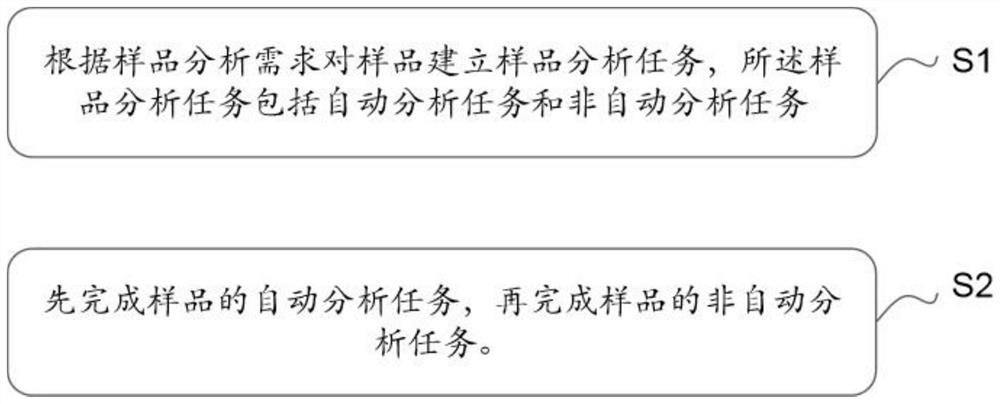

[0058] Such as figure 1 As shown, this embodiment discloses a sample analysis method of a spent fuel reprocessing plant, which includes:

[0059] Establish sample analysis tasks for samples according to sample analysis requirements. Sample analysis tasks include automatic analysis tasks and non-automatic analysis tasks;

[0060] Complete the automatic analysis task of the sample first, and then complete the non-automatic analysis task of the sample.

[0061] In some embodiments, before the sample analysis task is established for the sample, the method of this embodiment further includes: classifying the sample type according to the radioactive level of the sample, and the sample type includes a high-radioactive sample 10, a medium-radioactive sample 20, and a low-radioactive sample 30 (including very low level samples).

[0062] In this example, the radioactive level of the high-level sample is greater than or equal to n×10 9 Bq / L(n6 Bq / L(n9 Bq / L(n6 Bq / L (n<10).

[0063] ...

Embodiment 2

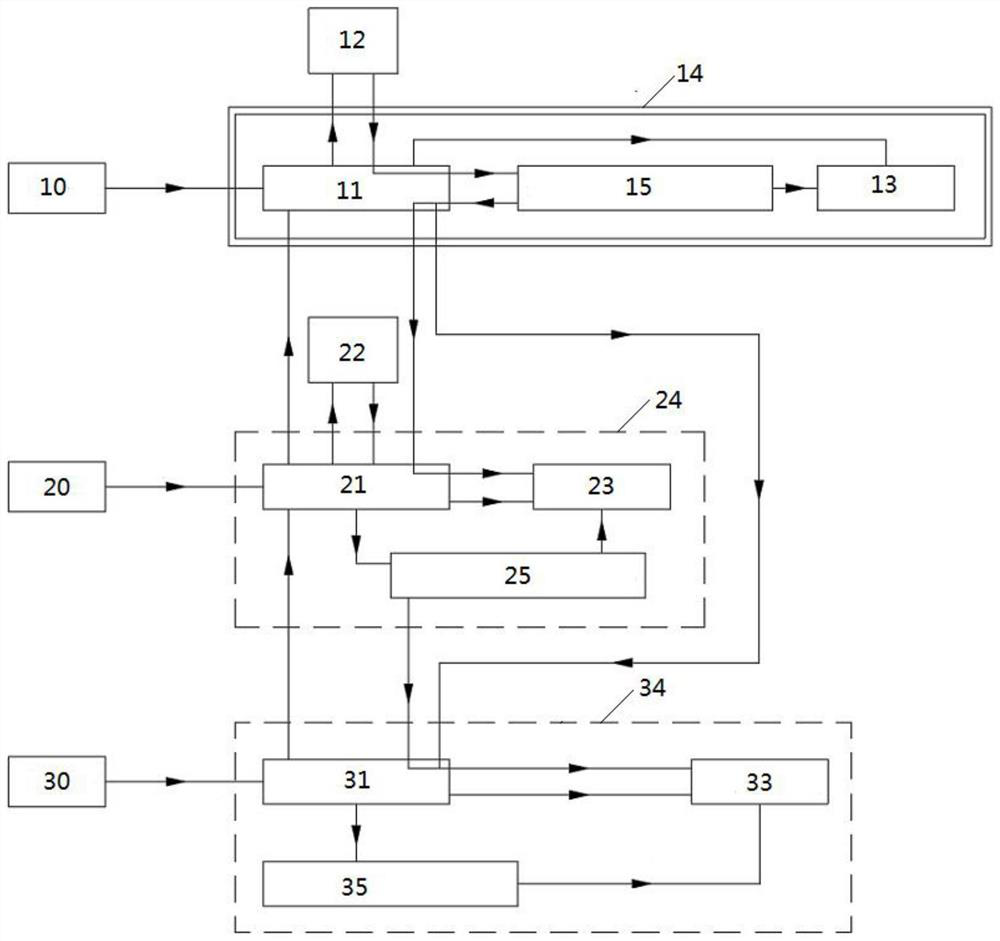

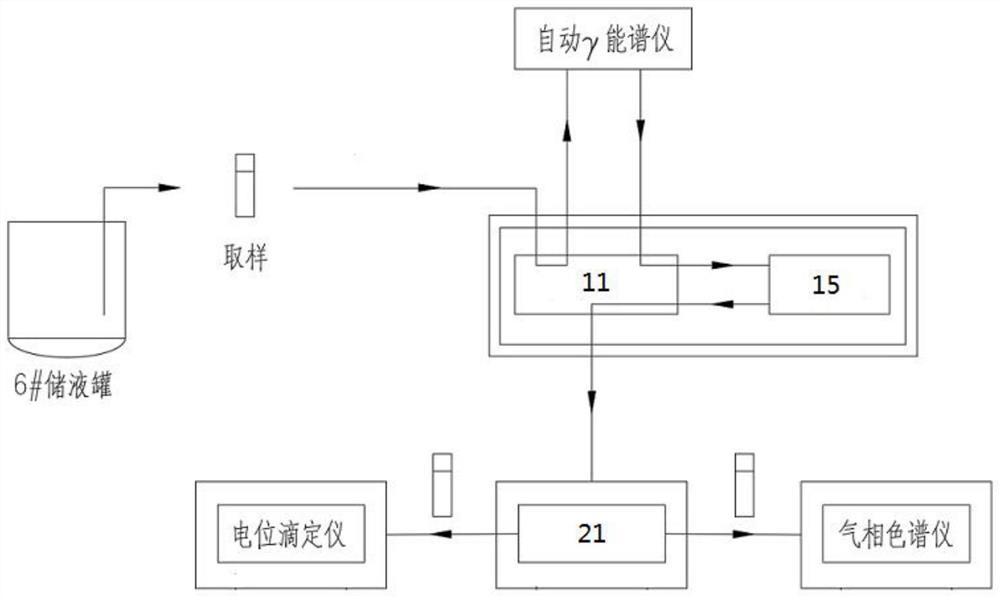

[0087] Such as figure 2 As shown, this embodiment discloses a spent fuel reprocessing plant sample analysis system, which can be used in the spent fuel reprocessing plant sample analysis method described in Example 1, which includes a transceiver unit, automatic analysis equipment, and a non-automatic analysis unit ,in:

[0088] A transceiver unit for receiving samples and distributing samples according to sample analysis tasks;

[0089] Automatic analysis equipment, used to receive the samples distributed by the transceiver unit and automatically analyze the samples, so as to complete the automatic analysis tasks of the samples;

[0090] The non-automatic analysis unit is used to receive the samples distributed by the transceiver unit and perform non-automatic analysis on the samples, so as to complete the non-automatic analysis tasks of the samples.

[0091] In some embodiments, the first shielded room 14, the second shielded room 24, and the third shielded room 34 are al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com