An Optical Fiber Sensing System for Vibration Testing of Engine Internal Flow Channels

An optical fiber sensing system and vibration testing technology, which is applied in engine testing, machine/structural component testing, measuring devices, etc., to achieve the effect of wide acceleration measurement range and wide frequency response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

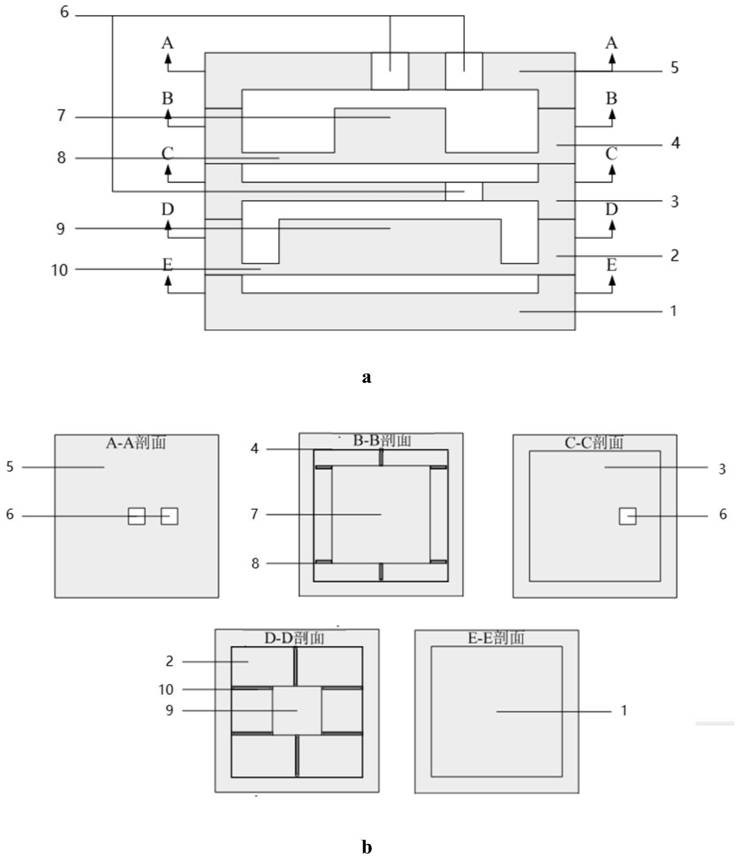

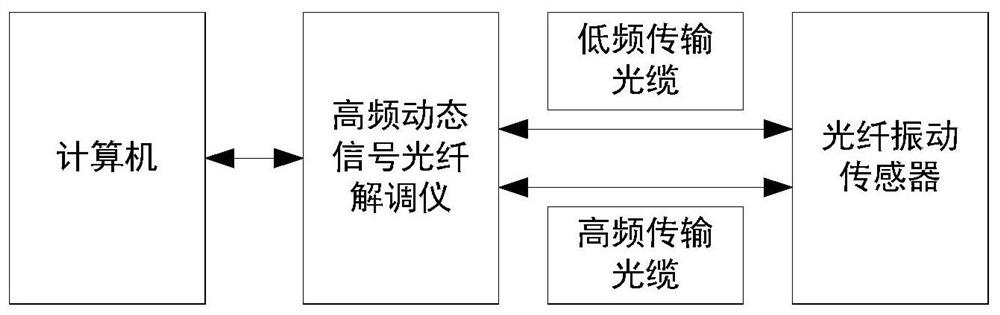

[0024] An optical fiber sensing system for vibration testing of a flow channel in an engine comprises an optical fiber vibration sensor, a transmission optical cable, a high-frequency dynamic signal optical fiber demodulator and a computer.

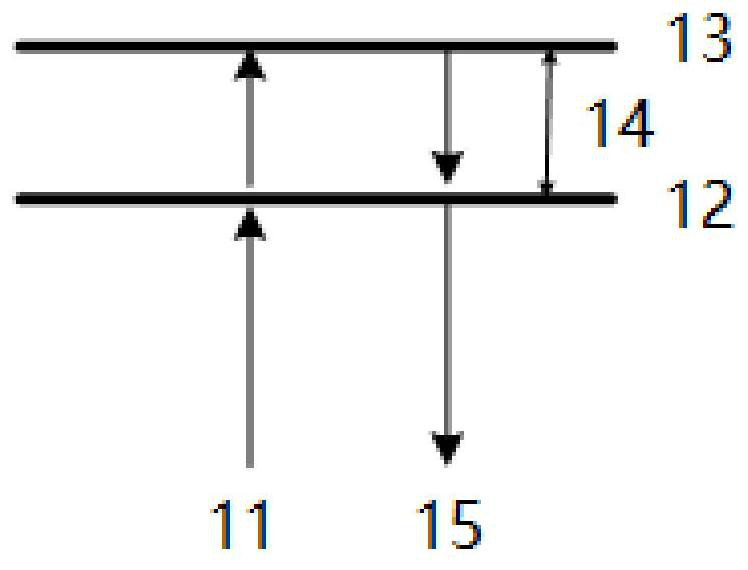

[0025] The optical fiber vibration sensor includes: a substrate 1, a low-frequency sensitive structural layer 2, a limiting layer 3, a high-frequency sensitive structural layer 4 and a protective layer 5; the substrate 1 is a groove structure; the middle of the low-frequency sensitive structural layer 2 is The mass block 9 is connected and fixed by the cantilever beam 10; the limiting layer 3 is a structure with grooves on the upper and lower sides, and a through hole 6 in the middle; the high frequency sensitive structure layer 4 has a structure in the middle. The mass block 7 is connected and fixed by the cantilever beam 8 ; the protective layer 5 is a groove structure with two through holes 6 .

[0026]The acceleration measurement rang...

Embodiment 2

[0030] An optical fiber sensing system for vibration testing of a flow channel in an engine comprises an optical fiber vibration sensor, a transmission optical cable, a high-frequency dynamic signal optical fiber demodulator and a computer.

[0031] The optical fiber vibration sensor includes: a substrate 1, a low-frequency sensitive structural layer 2, a limiting layer 3, a high-frequency sensitive structural layer 4 and a protective layer 5; the substrate 1 is a groove structure; the middle of the low-frequency sensitive structural layer 2 is The mass block 9 is connected and fixed by the cantilever beam 10; the limiting layer 3 is a structure with grooves on the upper and lower sides, and a through hole 6 in the middle; the high frequency sensitive structure layer 4 has a structure in the middle. The mass block 7 is connected and fixed by the cantilever beam 8 ; the protective layer 5 is a groove structure with two through holes 6 .

[0032] The acceleration measurement ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com