Locomotive driver auxiliary monitoring system and method for monitoring locomotive equipment operation

A monitoring system and locomotive driver's technology, applied in the locomotive driver's auxiliary monitoring system and used to monitor the operation of locomotive equipment, to achieve strong flexibility, convenient use, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

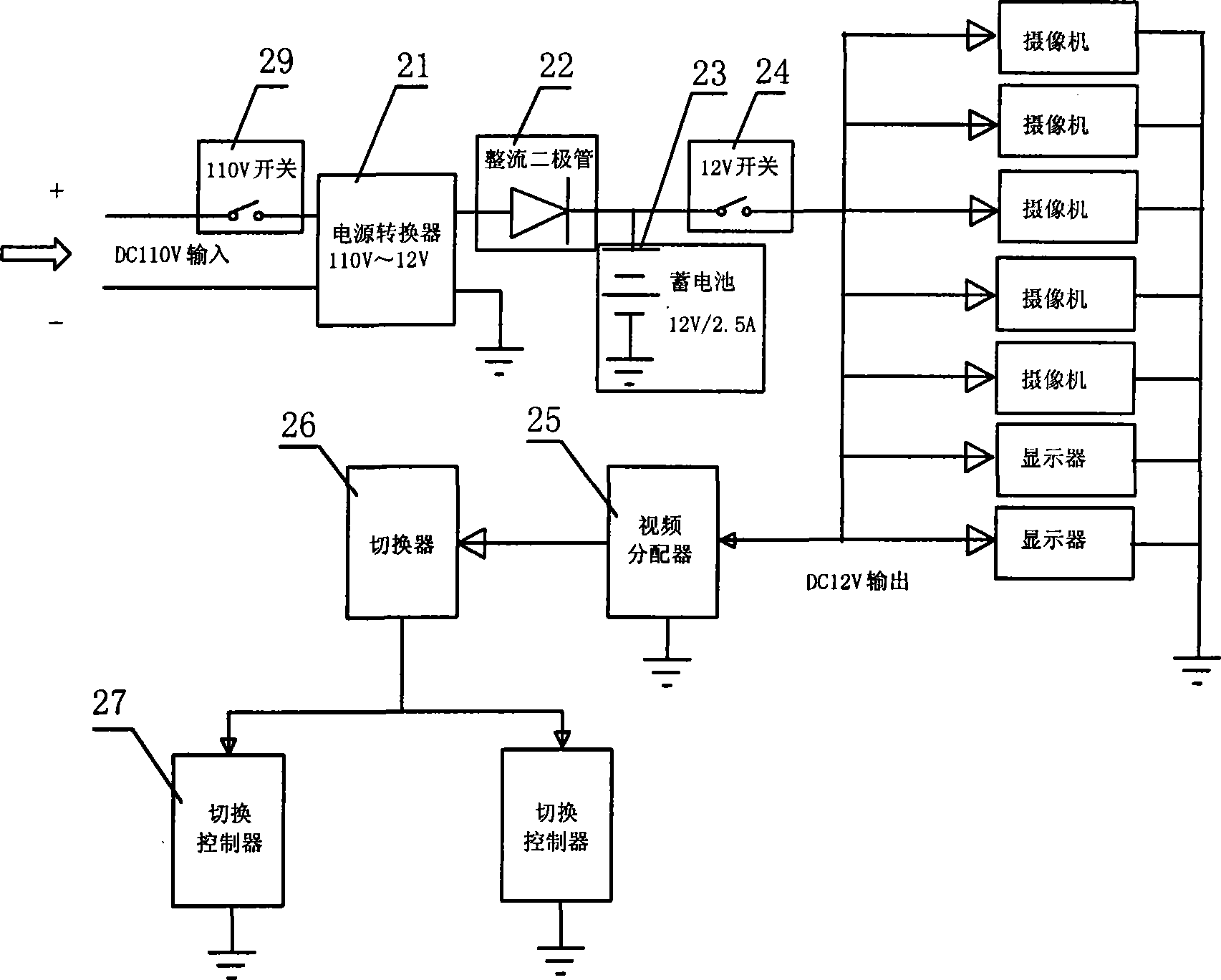

[0039] An auxiliary monitoring system for locomotive drivers, such as figure 1 As shown, the system includes 5 high-temperature-resistant cameras and a camera part I composed of auxiliary light sources connected to the camera, a switching control host II, and two 10" TFT liquid crystal displays III 1 , III 2 The constituted display unit III, 5 cameras are respectively installed in the operation monitoring area of each device by means of special brackets, and connected to the switching control host II through a special video and power integrated line IV, and its main function is to capture image signals of the monitoring area;

[0040]The switching control host is composed of a power converter 21, a rectifier diode 22, a 12V battery 23, one 8-in 16-out video distribution module 25, and two 8-channel video switch modules 26 connected in sequence. 1 , 26 2 As well as the switching controller 27, the 12V battery 23 is used as a backup power supply, and the rectifier diode 22 forms ...

Embodiment 2

[0053] A method for monitoring the operation of locomotive equipment by a locomotive driver’s auxiliary monitoring system is to install the five cameras of the locomotive driver’s auxiliary monitoring system described in the first embodiment of the present invention in five equipment operation monitoring areas, and connect the display unit and The switch control handle is installed near the operating platform of the driver's locomotive, and the switch control host is installed in the spare part of the three electrical cabinets of the locomotive. The video signals captured by the 5 cameras are transmitted back to the host through the dedicated video and power integrated line for video signal amplification, distribution and Switched and divided into 2 channels and transmitted to the LCD monitors in the No. 1 and No. 2 cabs through the dedicated video and power integrated lines respectively for display. The driver can observe through the LCD of the display unit without leaving the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com