Garbage furnace combustion air preheating system

A waste furnace and air technology, applied in preheating, combustion methods, components of steam boilers, etc., can solve the problems of wasting energy, underutilized heat of hydrophobicity, low thermal efficiency, etc., and achieve the effect of improving preheating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

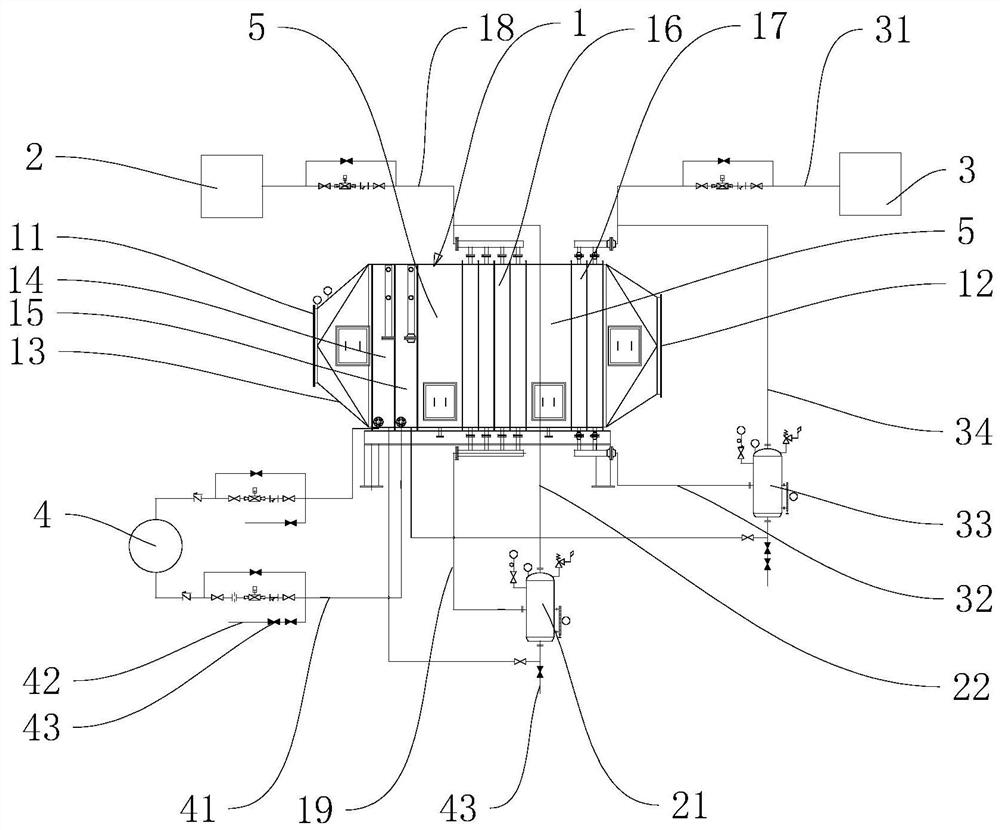

[0024] The application will be described in further detail below in conjunction with the accompanying drawings.

[0025] refer to figure 1 , the embodiment of the present application discloses a preheating system for combustion air of a garbage furnace, including a steam source and a heat exchange device 1 , and the heat exchange device 1 has an air inlet 11 and an air outlet 12 . The heat exchange device 1 includes a casing 13 , a hydrophobic heating stage and a steam heating stage. An air passage is formed in the casing 13 , and the hydrophobic heating stage and the steam heating stage are located in the air passage. The steam source includes a first steam source 2 and a second steam source 3, the hydrophobic heating stage includes a first hydrophobic heating stage 14 and a second hydrophobic heating stage 15, and the steam heating stage includes a first steam heating stage 16 and a second steam heating stage 17 . The gas pressure of the first steam source 2 is lower than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com