Petroleum pipeline supporting seat

A technology for oil pipelines and support seats, which is applied in the directions of pipeline supports, pipes/pipe joints/pipe fittings, mechanical equipment, etc. The effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

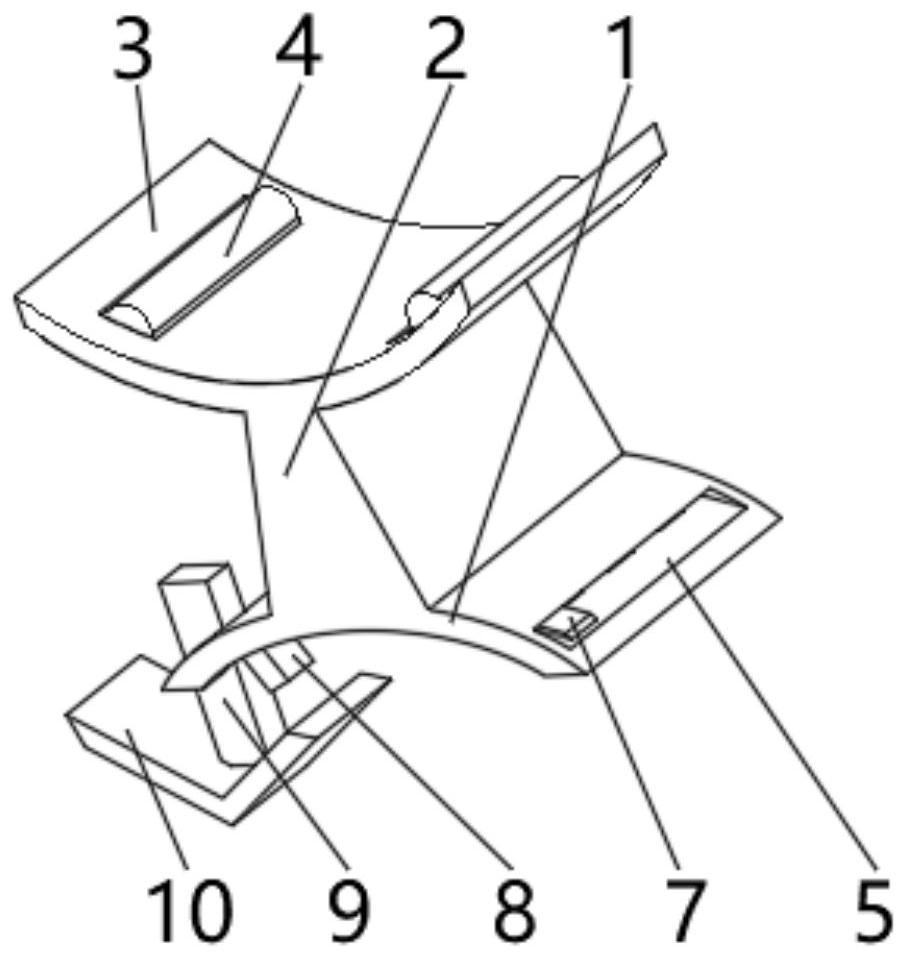

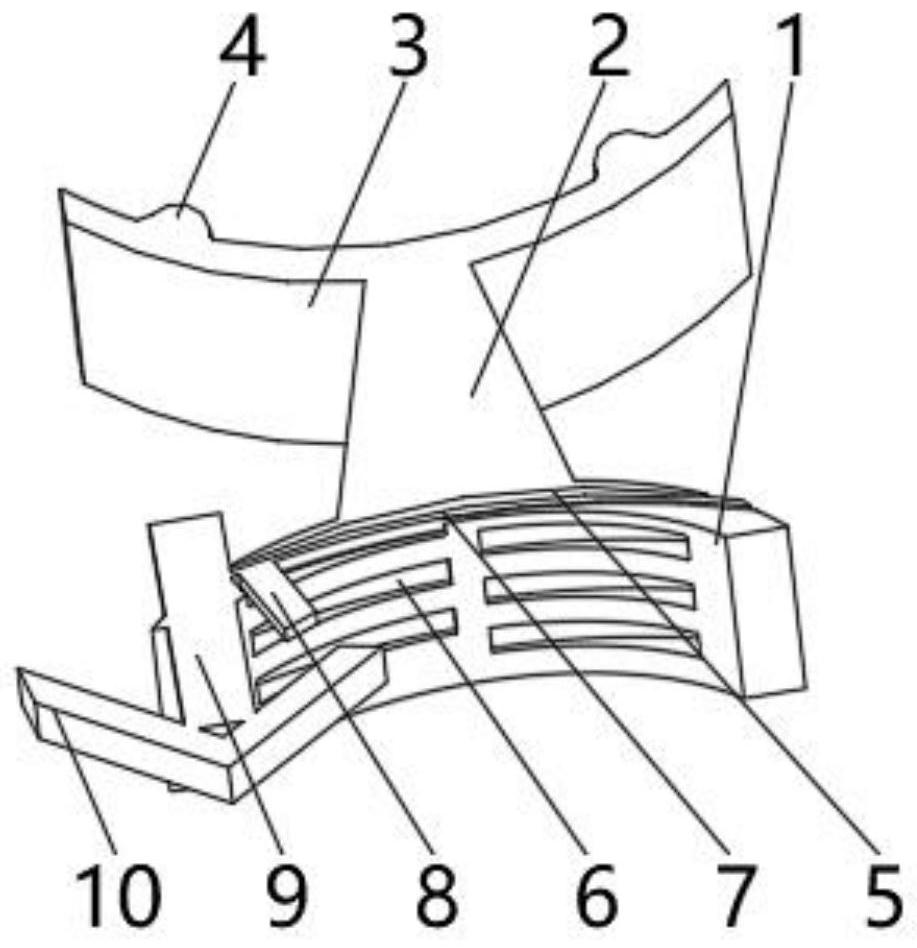

[0033] see Figure 1-3 , the present invention provides a technical solution: a support base for oil pipelines, including a bottom plate 1, the top of the bottom plate 1 is fixedly connected with a support arc plate 3 through a support rod 2, and the top of the support arc plate 3 is symmetrically installed with an alignment device 4, The inside of the base plate 1 is provided with an anti-settling groove 5, and both ends of the anti-settling groove 5 run through the base plate 1, and the bottom of the base plate 1 is uniformly provided with a trigger groove 6, and the trigger groove 6 communicates with the anti-settling groove 5, and the inside of the anti-settling groove 5 The bottom is slidably connected with an anti-settling plate 7 , and the bottom of the anti-settling plate 7 is fixedly connected with a trigger plate 8 , and the end of the trigger plate 8 away from the anti-settling plate 7 penetrates the trigger groove 6 and extends to the outside of the bottom plate 1 ....

Embodiment 2

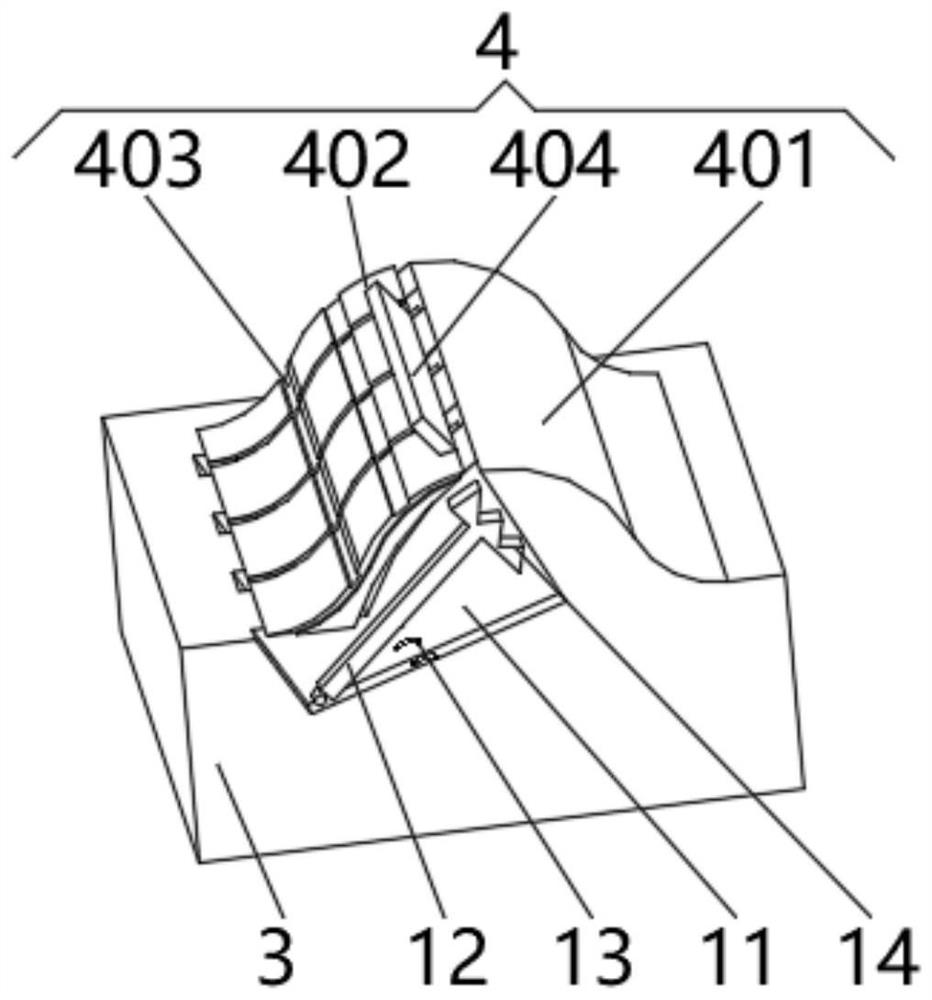

[0037] see Figure 1-3 , the present invention provides a technical solution: on the basis of Embodiment 1, the top of the supporting arc plate 3 is located below the fragile block 402 and is provided with an anti-skid groove 11, and the inner bottom of the anti-skid groove 11 is rotatably connected with a swing rod 12, swinging The bottom of the rod 12 is fixedly connected with the inner wall of the anti-skid groove 11 through the anti-skid spring 13 , and one end of the swing rod 12 is fixedly connected with an anti-skid tooth block 14 .

[0038]During use, when the support arc plate 3 tilts, the fragile block 402 is squeezed and broken, and the anti-skid spring 13 pushes the swing bar 12 to rotate to the outside of the anti-skid groove 11, and the oil pipe slides into the tilted swing bar 12 and the fixed block 401. The anti-slip eating block 14 is supported, which can strengthen the connection between the oil pipe and the fixed block of the lever function, prevent the oil ...

Embodiment 3

[0040] see Figure 1-6 , the present invention provides a technical solution: on the basis of Embodiment 1, the bottom of the bottom plate 1 is connected with the guide plate 10 through the sinking device 9, the sinking device 9 includes a fixed rod 901, and the fixed rod 901 is fixedly connected with the bottom plate 1, One end of the bottom of the fixed rod 901 is covered with a lifting outer frame 902 , and both sides of the lifting outer frame 902 are provided with feeding ports 903 .

[0041] Both sides of the inner wall of the lifting outer frame 902 are rotatably connected with a compacting plate 15, the bottom of the compacting plate 15 is corrugated, and the bottom of the compacting plate 15 is fixedly connected with a lifting plate 16, and the lifting plate 16 is far away from one end of the compacting plate 15 It runs through the lifting outer frame 902 and extends to the outside of the lifting outer frame 902 .

[0042] The outer side of the lifting plate 16 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com