Anti-scaling and corrosion-inhibiting device for electric submersible pump

A submersible electric pump and anti-corrosion technology, which is applied to pump devices, components of pumping devices for elastic fluids, pumps, etc., can solve problems such as wear, clogging and corrosion of separators and submersible electric pumps, and achieve The effect of reducing the probability of molecular condensation, changing the tendency of crystallization nucleation, and prolonging the maintenance period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] refer to figure 1 , an anti-scaling and corrosion-inhibiting device for an electric submersible pump, comprising an upper transport cap 1, an upper joint 2, a housing 3, a central shaft 5, an intermediate joint 7, a lower joint 8, a lower transport cap 9 and an induction separation wheel 10, The outside of the central shaft 5 is sleeved with a housing 3, the left end of the housing 3 is connected to the upper transport cap 1 through the upper joint 2, the right end of the housing 3 is connected to the lower transport cap 9 through the lower joint 8, and the central shaft 5 has two , the two central shafts 5 are connected through the intermediate connector 7, the outer of the central shaft 5 is sleeved with a bushing 14, the bushing 14 is located on the inner wall of the housing 3, between the central shaft 5 and the upper joint 2, the central shaft 5 and the middle connecting head 7, the central shaft 5 and the lower joint 8 are connected to each other through an alloy ...

Embodiment 2

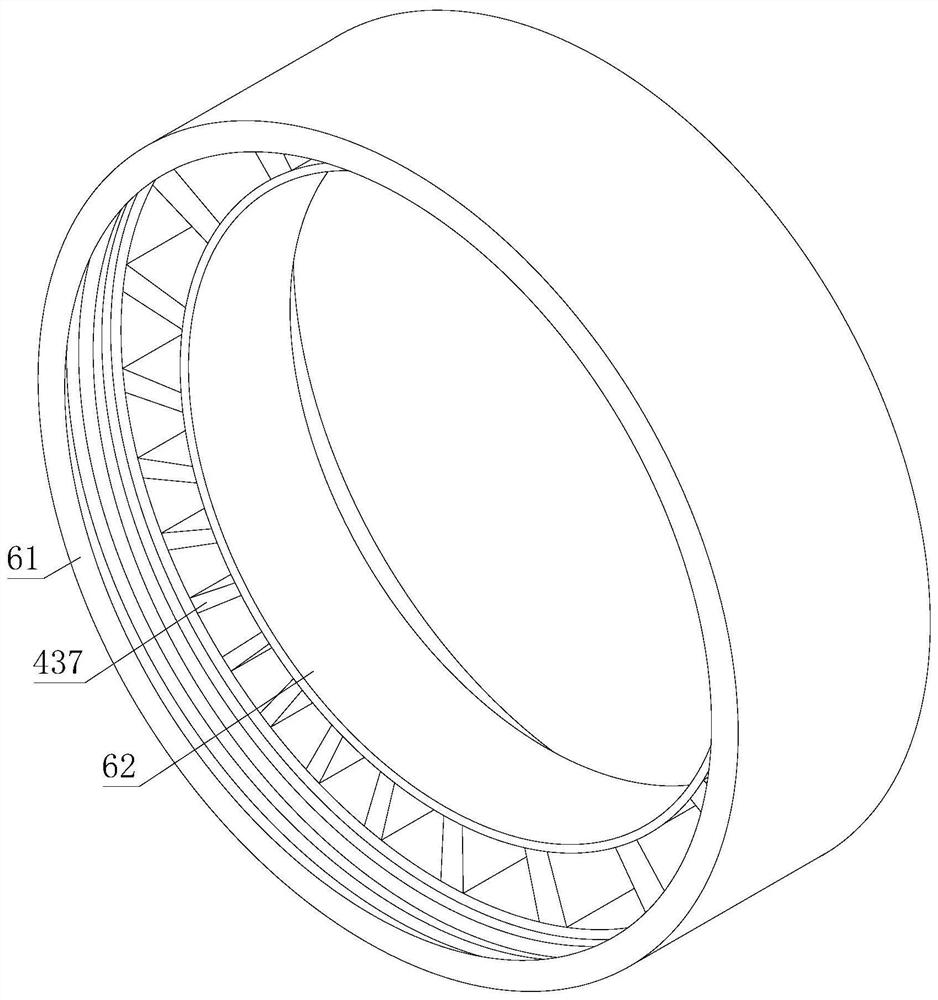

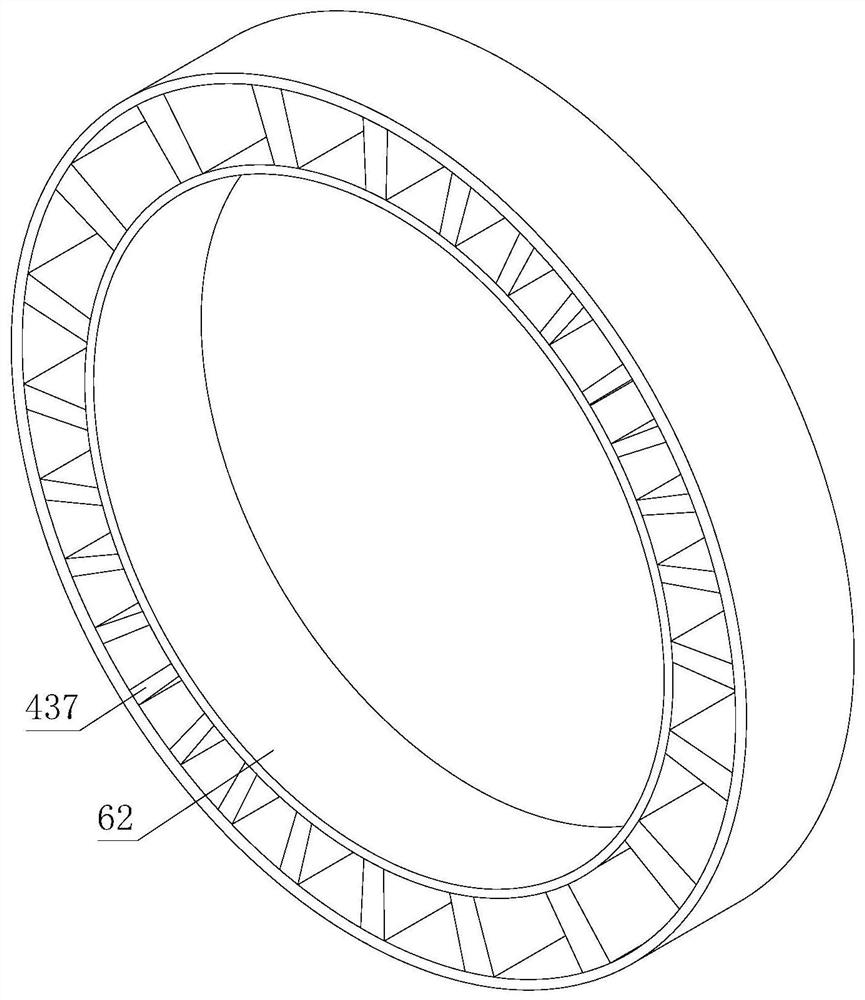

[0036] refer to Figure 9 , the beam 438 and the longitudinal beam 439 are composed of multiple anti-scale and corrosion inhibition alloy sheets 437, the side of the anti-scale and corrosion inhibition alloy sheet 437 is connected to the side of another anti-scale and corrosion inhibition alloy sheet 437, two adjacent sheets The anti-scaling and corrosion-inhibiting alloy sheets 437 are V-shaped. The anti-scaling and corrosion-inhibiting alloy sheets 437 can not only prevent the scale and corrosion of the submersible electric pump, but also use the front anti-scaling and corrosion-inhibiting mechanism 6 pairs of induction separation wheels 10 to prevent the scale and corrosion. corrosion, slow down the scaling and corrosion of the oil on the separator and electric submersible pump, extend the maintenance cycle of the electric submersible pump, and improve the efficiency of the separator and electric submersible pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com