Preparation process of freeze-dried powder for detecting novel coronavirus

A technology of freeze-dried powder and preparation process, applied in the field of new coronavirus detection, can solve the problems of difficult removal of product moisture, easy collapse and shrinkage of the structure, long freeze-drying cycle, etc., to meet the performance of the positive and negative coincidence rate, and shorten the freeze-drying time. , the effect of high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

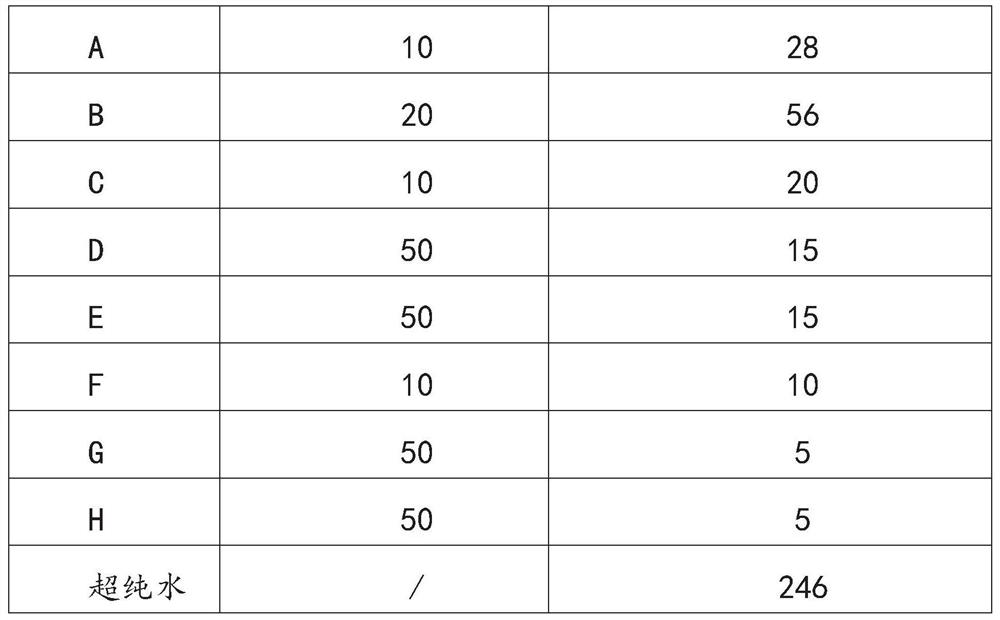

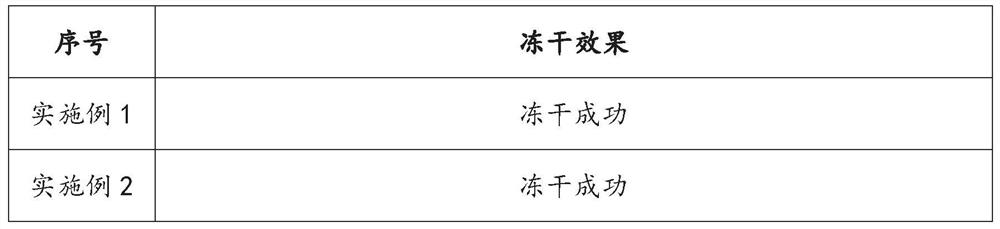

Embodiment 1

[0033] Place the eight-tube pre-freeze-dried product on the hollowed-out freeze-drying mold in the freeze-dryer in a half-jammed state, and use the convective heat transfer method to freeze-dry: (1) During freezing control, the temperature drops to - within 60 minutes. Keep at 45°C for 2 hours, so that the water in the product is completely frozen; (2) When drying once, vacuumize to 0.2mbar within 2min, and keep at -45°C for 30min; then keep the vacuum at 0.2mbar, within 20min Raise the temperature to -32°C and keep it for 960min; (3) When analyzing and drying, in an environment with a vacuum degree below 0.39mbar, the temperature is raised to 20°C within 100min and kept for 2h; within 2min, the vacuum is evacuated to 0mbar and kept for 10min. After analysis and drying, carry out negative pressure plugging under the condition of extreme vacuum in the freeze dryer, and after the plugging is completed, take out the material and store it at a low temperature of 2-8°C.

Embodiment 2

[0035] Place the eight-tube pre-freeze-dried product on the hollowed-out freeze-drying mold in the freeze-dryer in a half-jammed state, and use the convective heat transfer method to freeze-dry: (1) During freezing control, the temperature drops to - within 60 minutes. Keep at 45°C for 2 hours, so that the water in the product is completely frozen; (2) When drying once, vacuumize to 0.2mbar within 2min, and keep at -45°C for 30min; then keep the vacuum at 0.2mbar, within 20min Raise the temperature to -32°C and keep it for 1110min; (3) When analyzing and drying, in an environment with a vacuum degree below 0.39mbar, the temperature is raised to 20°C within 100min and kept for 2h; within 2min, the vacuum is evacuated to 0mbar and kept for 10min. After analysis and drying, carry out negative pressure plugging under the condition of extreme vacuum in the freeze dryer, and after the plugging is completed, take out the material and store it at a low temperature of 2-8°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com