System and method for separating polycyclic aromatic hydrocarbon by using deep eutectic solvent

A technology for deep eutectic solvents and polycyclic aromatic hydrocarbons, which is applied in the fields of refining and treating hydrocarbon oil with two or more solvents, and the petroleum industry. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

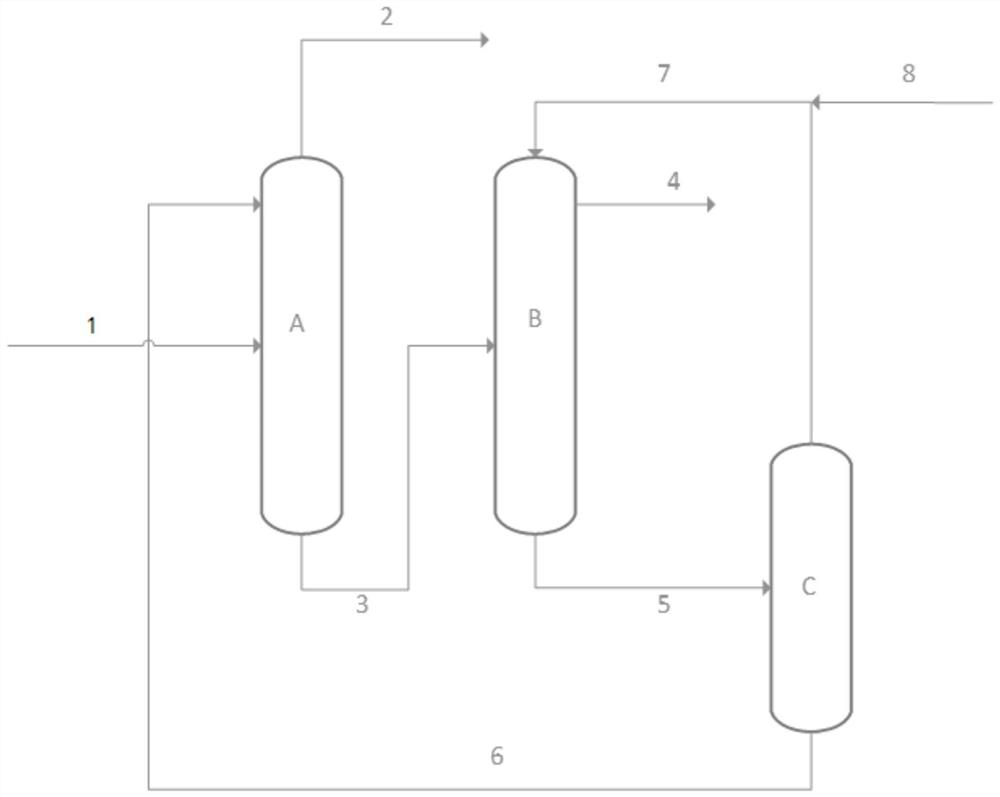

[0043] Building system: the system for separating polycyclic aromatic hydrocarbons with deep eutectic solvents includes polycyclic aromatic hydrocarbons separation unit A tower, polycyclic aromatic hydrocarbons removal unit B tower, deep eutectic solvent regeneration unit C tower; wherein, the polycyclic aromatic hydrocarbons separation unit A Tower one outlet is connected to said polycyclic aromatic hydrocarbons removal unit B tower one inlet through pipeline 3;

[0044] An outlet of the polycyclic aromatic hydrocarbon removal unit B tower is connected to an inlet of the deep eutectic solvent regeneration unit C tower through a pipeline 5, and the deep eutectic solvent regeneration unit C tower includes two outlets, and an outlet is connected by a pipeline 7 A tower top inlet is connected to the PAH removal unit B tower, and the other outlet is connected to an inlet of the PAH separation unit A tower through a line 6.

[0045] The method of carrying out deep eutectic solvent ...

Embodiment 2

[0050] The same system as in Example 1 was used.

[0051] The method of carrying out deep eutectic solvent separation polycyclic aromatic hydrocarbons:

[0052] Using the raw oil with the same composition as in Example 1, the mass composition of the stream is 7% non-aromatic, 39% monocyclic aromatics, and 54% polycyclic aromatics. The raw oil is introduced into tower A of PAH separation unit through pipeline 1, and fresh deep eutectic solvent is introduced into tower A through pipeline 6 through the top of the tower. The solvent is obtained by mixing and stirring at 60°C before use. The solvent is composed of methyltriphenylphosphonium bromide / dimethylformamide with a molar ratio of 1 / 3 and the addition of SnCl with a mass of 1% of the total mass of the deep eutectic solvent. 2 composition. The volume ratio of the deep eutectic solvent to the oil to be extracted is 1 / 1.5. After extraction, the side line 2 produces a mixed component of single-ring aromatics and non-aromatics....

Embodiment 3

[0056] The same system as in Example 1 was used.

[0057] The method of carrying out deep eutectic solvent separation polycyclic aromatic hydrocarbons:

[0058] Using the raw oil with the same composition as in Example 1, the mass composition of the stream is 7% non-aromatic, 39% monocyclic aromatics, and 54% polycyclic aromatics. The raw oil is introduced into tower A of PAH separation unit through pipeline 1, and fresh deep eutectic solvent is introduced into tower A through pipeline 6 through the top of the tower. The solvent is obtained by mixing and stirring at 60°C before use. The solvent consists of methyltriphenylphosphonium bromide / succinic acid with a molar ratio of 1 / 3 and the addition of SnCl with a mass of 1% of the total mass of the deep eutectic solvent. 2 Composition, the volume ratio of the deep eutectic solvent to the oil to be extracted is 1 / 1.5, after extraction, the side line 2 produces a mixed component of single-ring aromatics and non-aromatics, the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com