Leacher and application thereof as well as device and method for recycling PVC (polyvinyl chloride)-containing waste plastics

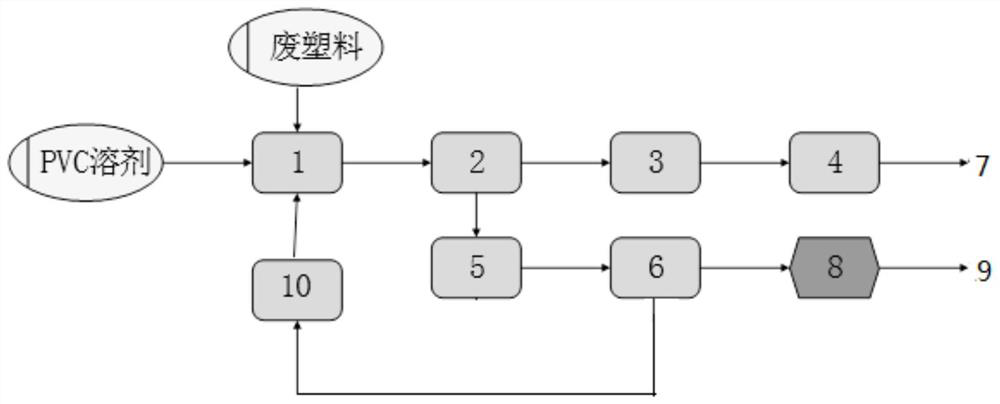

A technology of extractor and waste plastics, which is applied in the field of waste plastics recycling, can solve the problems of complex process flow of waste plastics, complex components that cannot be processed, and large amount of PVC solvent, so as to facilitate industrial production design, improve PVC dissolution efficiency, and improve The effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0055] In another embodiment of the present invention, the branch pipe assembly includes a first branch pipe, a connecting pipe and at least one second branch pipe, and the connecting pipe communicates with the first branch pipe and multiple second branch pipes.

[0056] Preferably, in each set of branch pipe assemblies, the first branch pipe communicates with the leaching liquid pipe, and the second branch pipe communicates with the dissolution pipe.

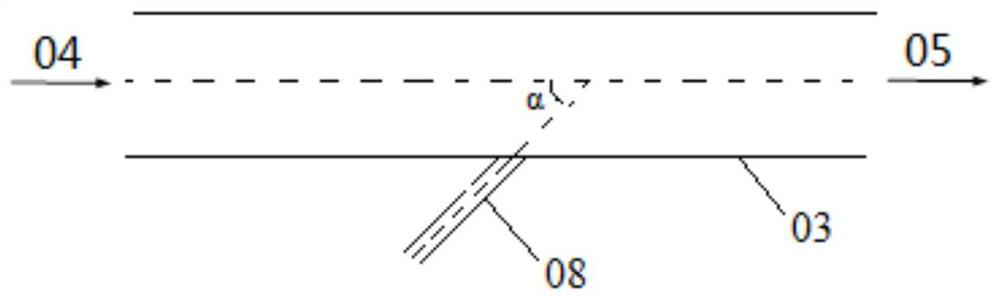

[0057] According to the present invention, preferably, along the flow direction of the material, the inner diameters of the plurality of first branch pipes decrease sequentially, and / or the inner diameters of the plurality of second branch pipes decrease sequentially. That is, according to the flow direction of the material, the total flux of the leachate in each group of branch pipe assemblies decreases sequentially. Wherein, the inner diameters of the plurality of first branch pipes are successively reduced, which means that ...

Embodiment 1

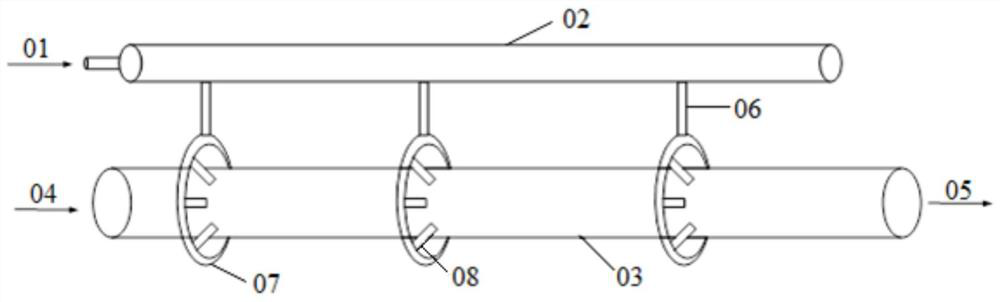

[0123] (1) Extractor such as figure 1 As shown, the extractor includes: leach solution inlet 01, leach solution pipe 02, three sets of branch pipe assemblies, dissolving pipe 03, material inlet 04 and mixture outlet 05, and each set of branch pipe assemblies includes: first branch pipe 06, A connecting pipe 07 and six second branch pipes 08, the connecting pipe 07 communicates with the first branch pipe 06 and the six second branch pipes 08, and the branch pipe assembly is used to distribute the leachate in the leachate pipe 02 to In the dissolving pipe 03, the dissolving pipe 03 is used to mix and dissolve the leaching solution and the materials in the dissolving pipe 03 to obtain a mixture; the leaching solution inlet 01 is set at the leaching solution On the pipe 02, and perpendicular to the center of the end face of the leach liquid pipe 02; according to the flow direction of the flow, one end of the dissolving pipe 03 is the material inlet 04, and the other end is the mix...

Embodiment 2

[0134] (1) Extractor such as figure 1 As shown, the extractor includes: leach solution inlet 01, leach solution pipe 02, five sets of branch pipe assemblies, dissolving pipe 03, material inlet 04 and mixture outlet 05, and each set of branch pipe assemblies includes: first branch pipe 06, A connecting pipe 07 and six second branch pipes 08, the connecting pipe 07 communicates with the first branch pipe 06 and the six second branch pipes 08, and the branch pipe assembly is used to distribute the leachate in the leachate pipe 02 to In the dissolving pipe 03, the dissolving pipe 03 is used to mix and dissolve the leaching solution and the materials in the dissolving pipe 03 to obtain a mixture; the leaching solution inlet 01 is set at the leaching solution On the pipe 02, and perpendicular to the center of the end face of the leaching liquid pipe 02; according to the flow direction of the stream, one end of the dissolving pipe 03 is the material inlet 04, and the other end is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com