Anti-fitting automatic withdrawing device for motor stator insulation paper

A technology for a motor stator and a removal device, which is applied to electromechanical devices, electric components, and the manufacture of motor generators, can solve the problems of low efficiency, difficulty in removing stator insulating paper, and manual removal efficiency, and achieves improved stability, reduced work intensity, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

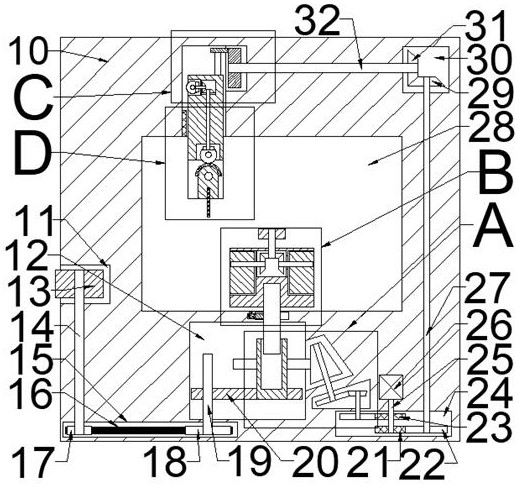

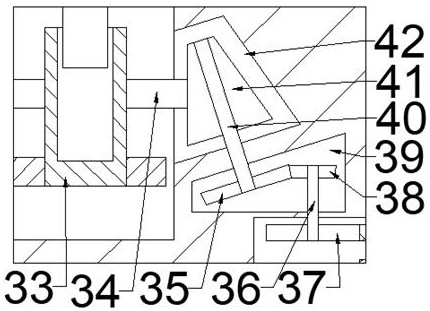

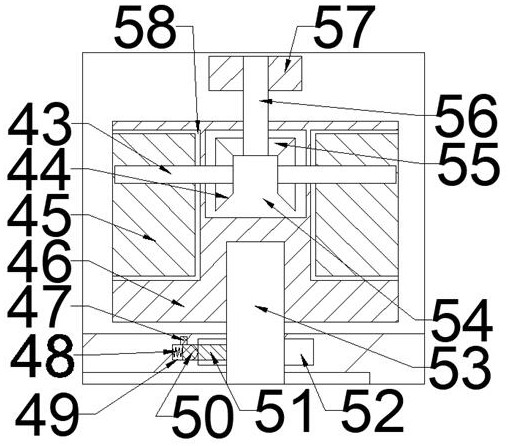

[0018] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0019] combined with Figure 1-5The described automatic anti-adhesion removal device for motor stator insulation paper includes a main box body 10, and a processing chamber 28 with an opening forward is arranged inside the main box body 10, and a reciprocating Sliding cavity 59, between the front and rear end walls of the reciprocating sliding cavity 59, a reciprocating slide seat 69 is slidably connected, and the reciprocating sliding seat 69 is provided with a take-out gear cavity 66 with an opening to the left, and the take-out gear cavity 66 on the right side A take-out bevel tooth chamber 60 is provided, and the lower side of the take-out bevel tooth chamber 60 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com