Freeze-thaw resistant concrete and preparation method thereof

A freeze-thaw resistance and concrete technology, applied in the field of concrete, can solve the problems of poor freeze-thaw resistance of freeze-thaw-resistant concrete, improve the poor freeze-thaw resistance, improve the bonding strength, and improve the anti-cracking performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

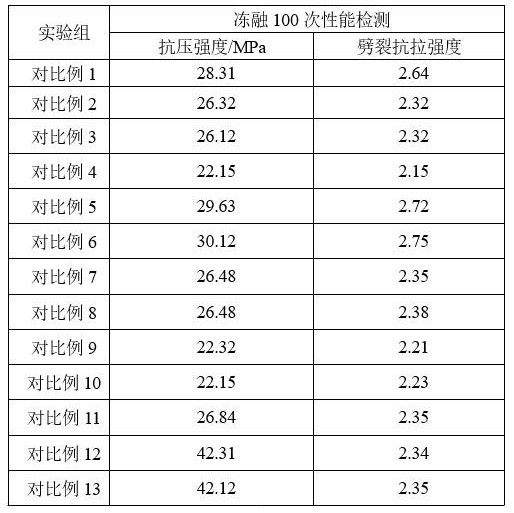

Examples

preparation example 1

[0045] Composite sol preparation: Add 200g of ammonium nitrate to 5000g of deionized water, stir and mix and collect the mixed solution, then add 500g of aluminum isopropoxide to the mixed solution, stir and mix at room temperature, collect the reaction solution and place it at 45°C Next, add 250g tetraethyl orthosilicate to the reaction solution, stir for 6 hours, let it stand for aging and collect the modified sol solution, mix the modified sol solution with the porous silica sol at a mass ratio of 1:1 and Homogenize at 4500r / min for 25min to obtain composite sol 1;

[0046] Preparation of freeze-thaw resistant modified fiber: take 5000g of EVA resin, 4500g of TPE resin and 2000g of TPR resin in a mixer, mix and collect the elastomer mixture, put the elastomer mixture in the HAAKE micro mixing extruder, melt spinning Process and collect the spun blended elastomer fibers, control the spinning temperature to 185°C, the winding temperature to 20r / min, and the screw speed to 30r...

preparation example 2

[0048] Composite sol preparation: Add 220g of ammonium nitrate to 6000g of deionized water, stir and mix and collect the mixed solution, then add 55g of aluminum isopropoxide to the mixed solution, stir and mix at room temperature, collect the reaction solution and place it at 52°C Next, add 270g of tetraethyl orthosilicate to the reaction solution, stir for 7 hours, let it stand for aging and collect the modified sol solution, mix the modified sol solution with the porous silica sol at a mass ratio of 1:1 and Homogenized at 5200r / min for 27min to obtain composite sol 2;

[0049] Preparation of freeze-thaw resistant modified fiber: Take 5500g of EVA resin, 4750g of TPE resin and 2500g of TPR resin in a mixer, mix and collect the elastomer mixture, put the elastomer mixture in the HAAKE micro mixing extruder, melt spinning Process and collect the spun blended elastomer fibers, control the spinning temperature to 190°C, the winding temperature to 35r / min, and the screw speed to ...

preparation example 3

[0051] Composite sol preparation: Add 250g of ammonium nitrate to 8000g of deionized water, stir and mix and collect the mixed solution, then add 60g of aluminum isopropoxide to the mixed solution, stir and mix at room temperature, collect the reaction solution and place it at 60°C Next, add 300g tetraethyl orthosilicate to the reaction solution, stir for 8 hours, let it stand for aging and collect the modified sol, mix the modified sol with the porous silica sol at a mass ratio of 1:1 and Homogenize at 6000r / min for 30min to obtain composite sol 3;

[0052] Preparation of freeze-thaw resistant modified fiber: Take 6000g of EVA resin, 5000g of TPE resin and 3000g of TPR resin in a mixer, mix and collect the elastomer mixture, put the elastomer mixture in the HAAKE micro mixing extruder, melt spinning Process and collect the spun blended elastomer fibers, control the spinning temperature to 195°C, the coiling temperature to 50r / min, and the screw speed to 35r / min;

[0053] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com