Equipment and method for hydrogen production through reforming of methanol steam

A technology of steam reforming and hydrogen production equipment, which is applied to chemical instruments and methods, hydrogen, hydrogen separation, etc., can solve the problems of poor economy and high cost, and achieve the effects of reducing harmful gases, increasing concentration, and being environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

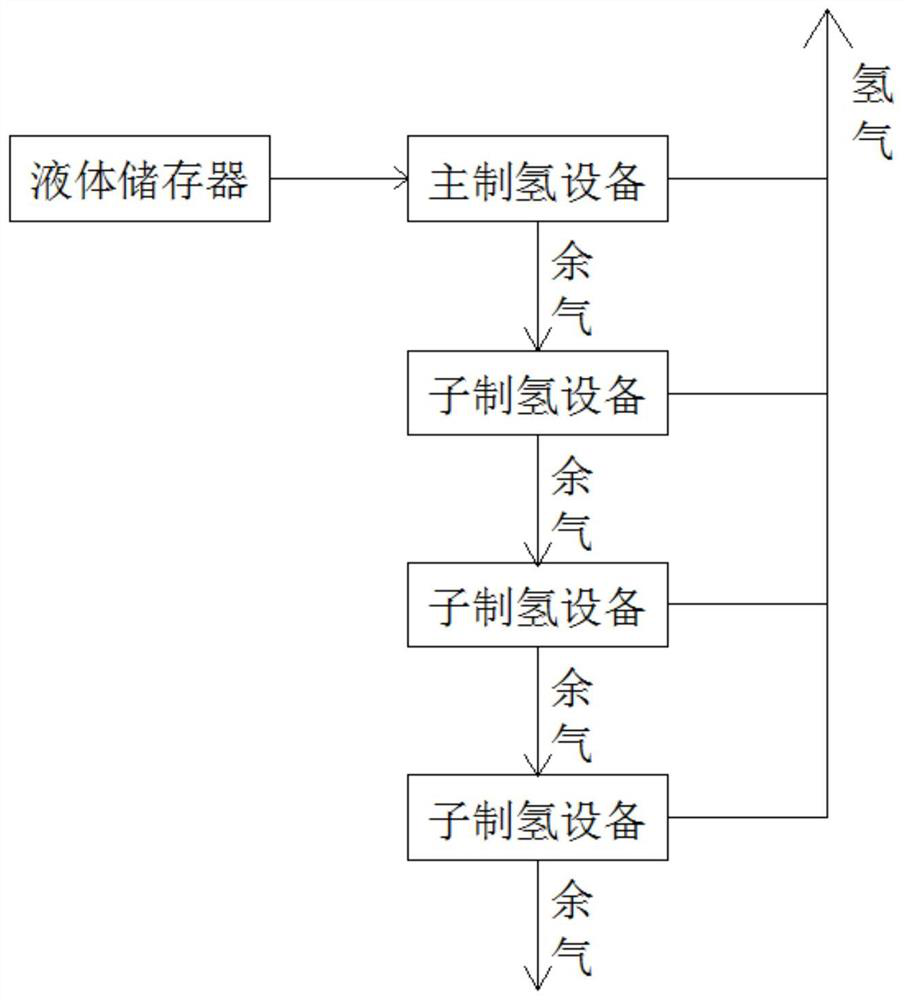

[0028] The present invention provides a methanol steam reforming hydrogen production equipment, which includes a liquid storage, a main hydrogen production equipment and three sub-hydrogen production equipment, wherein the main hydrogen production equipment includes heat exchangers connected in sequence through pipelines device, vaporization chamber, reforming chamber and separation chamber, the heat exchanger communicates with the liquid storage through pipelines; A sub-reforming chamber and a sub-separation chamber separated by a plate, and the partition plate is provided with a vent hole communicating with the sub-reforming chamber and the sub-separation chamber;

[0029] The main hydrogen production equipment obtains hydrogen, and at the same time transports the exhausted residual gas to one of the sub-hydrogen production equipments, wherein the first sub-hydrogen production equipment receives the exhausted residual gas from the main hydrogen production equipment, and then ...

Embodiment 2

[0032] The present invention provides a methanol steam reforming hydrogen production equipment, which includes a liquid storage, a main hydrogen production equipment and two sub-hydrogen production equipment, wherein, the main hydrogen production equipment includes heat exchangers connected in sequence through pipelines device, vaporization chamber, reforming chamber, preheating temperature control mechanism and separation chamber, the heat exchanger communicates with the liquid storage through pipelines; the sub-hydrogen production equipment includes a shell with an inner cavity, A sub-reforming chamber and a sub-separation chamber formed by separating the inner cavity of the housing through a partition, and the partition is provided with a vent hole communicating with the sub-reformation chamber and the sub-separation chamber;

[0033] The main hydrogen production equipment obtains hydrogen, and at the same time transports the exhausted residual gas to one of the sub-hydrogen...

Embodiment 3

[0036] The present invention provides a methanol steam reforming hydrogen production equipment, which includes a liquid storage, main hydrogen production equipment and four sub-hydrogen production equipment, wherein, the main hydrogen production equipment includes heat exchangers connected in sequence through pipelines device, vaporization chamber, reforming chamber, preheating temperature control mechanism and separation chamber, the heat exchanger communicates with the liquid storage through pipelines; the sub-hydrogen production equipment includes a shell with an inner cavity, A sub-reforming chamber and a sub-separation chamber formed by separating the inner cavity of the housing through a partition, and the partition is provided with a vent hole communicating with the sub-reformation chamber and the sub-separation chamber;

[0037]The main hydrogen production equipment obtains hydrogen, and at the same time transports the exhausted residual gas to one of the sub-hydrogen p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com