Method and device for converting catalytic cracking cycle oil in classified and divisional manner

A technology for catalytic cracking and circulating oil, which is used in the petroleum industry, processing hydrocarbon oil, hydrocarbon oil processing products, etc., and can solve problems such as lack of effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

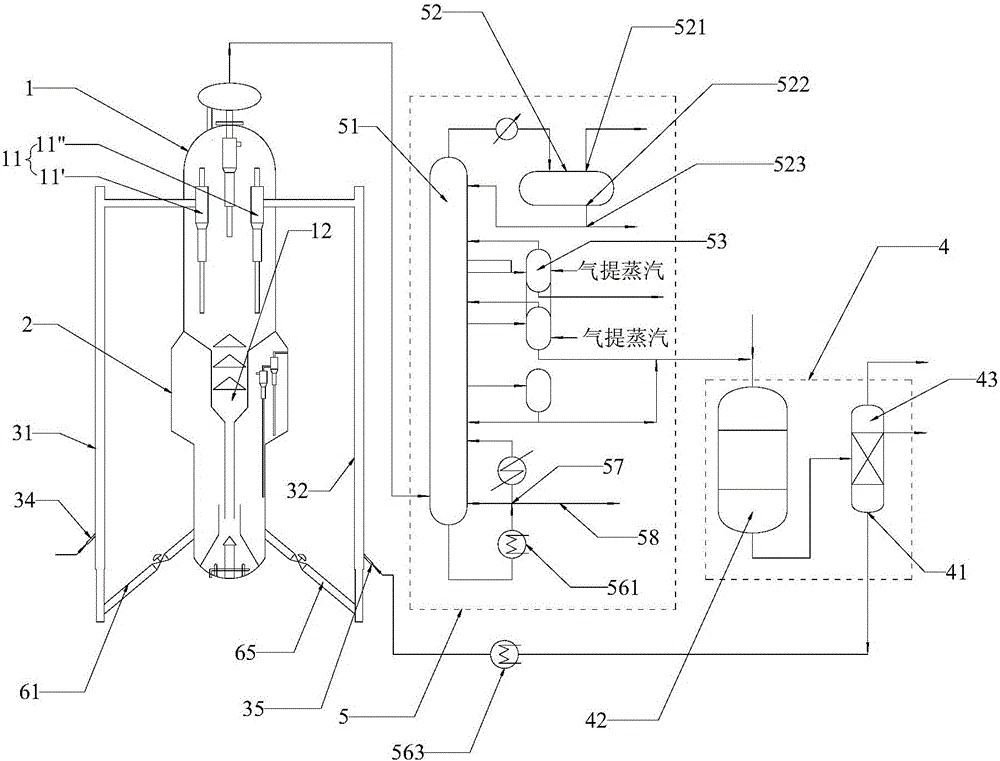

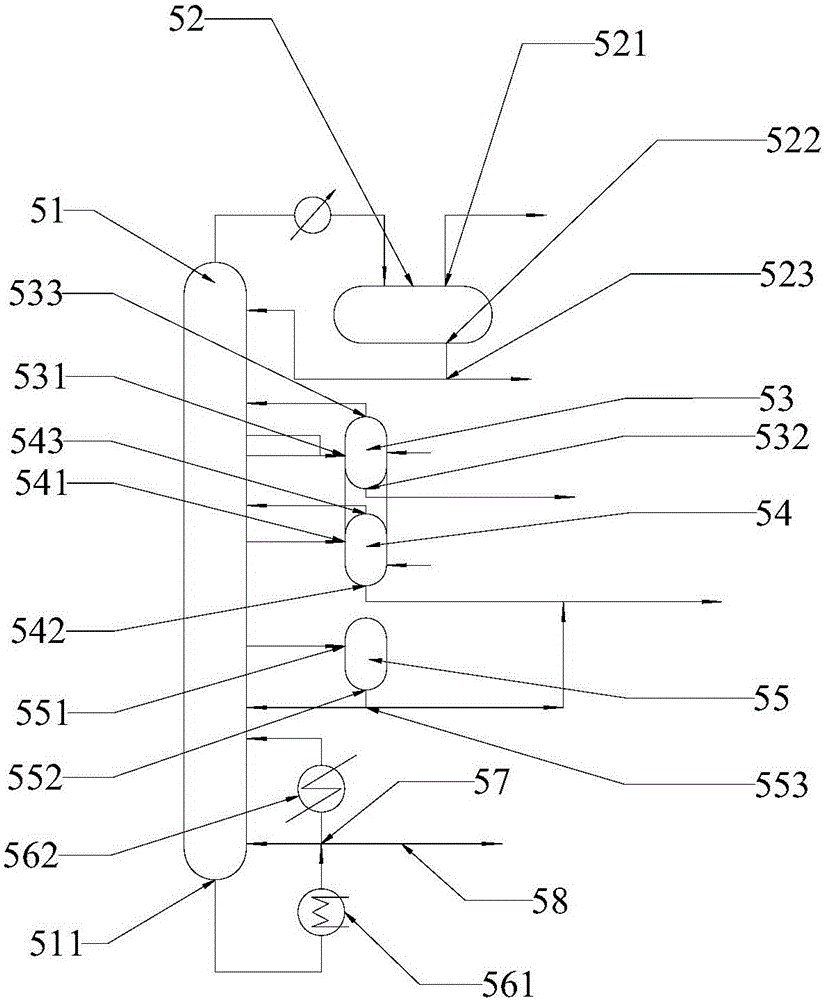

[0059] Device and flow process of the present invention can be seen figure 1 and figure 2 , briefly described as follows: the device includes a settler 1, a regenerator 2, a first riser reactor 31, a second riser reactor 32, a catalytic hydrogenation unit 4 and a fractionation unit 5, wherein the regenerator is arranged at the bottom of the settler , the first riser reactor and the second riser reactor are arranged in parallel, the tops of the two riser reactors are respectively connected to the two gas-solid separation devices 11' and 11" in the settler, and the two riser reactors The bottom is connected to the bottom of the regenerator through the first inclined pipe 61 and the second inclined pipe 62 respectively, the top of the settler is connected to the fractionation unit, and the fractionation unit is connected to the catalytic hydrogenation unit so that the light cycle oil and heavy cycle oil from the fractionation unit are Enter in the catalytic hydrogenation unit a...

Embodiment 2

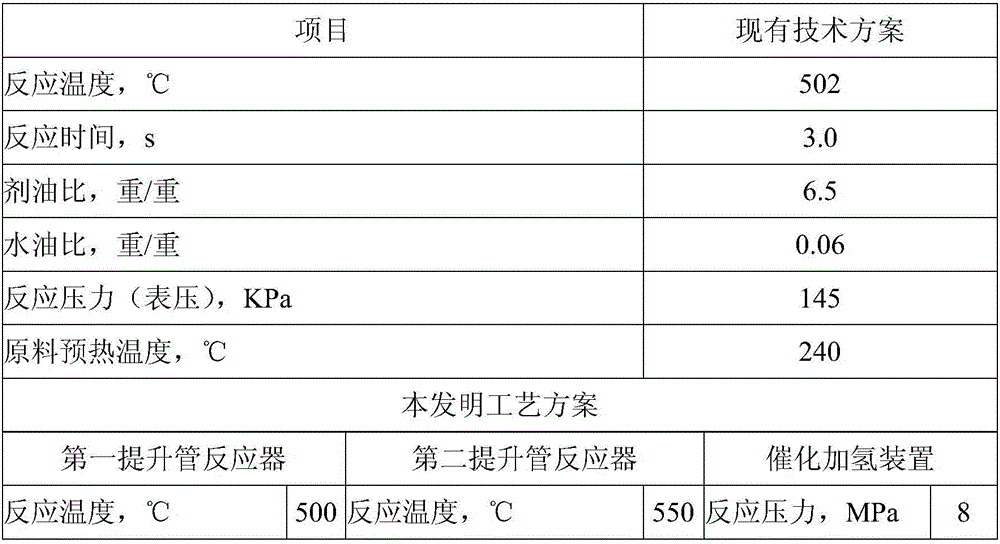

[0077] Other conditions remain unchanged, using the process conditions in Table 6, the effects shown in Table 7 can be obtained.

[0078] Table 6 main process conditions

[0079]

[0080]

[0081] Table 7 Distribution of main products

[0082] Product distribution and properties

Embodiment 3

[0084] Other conditions remain unchanged, using the process conditions in Table 8, the effects shown in Table 9 can be obtained.

[0085] Table 8 main process conditions

[0086]

[0087]

[0088] Table 9 Distribution of main products

[0089] Product distribution and properties

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com