Camellia procyanidine mask and preparation method thereof

A technology for proanthocyanidins and camellia, which is applied to the field of camellia proanthocyanidin facial mask and its preparation, can solve the problems of insufficient effective utilization of active substances, waste of resources and the like, and achieve important economic benefits and application prospects, fair skin, and the effects of improving environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

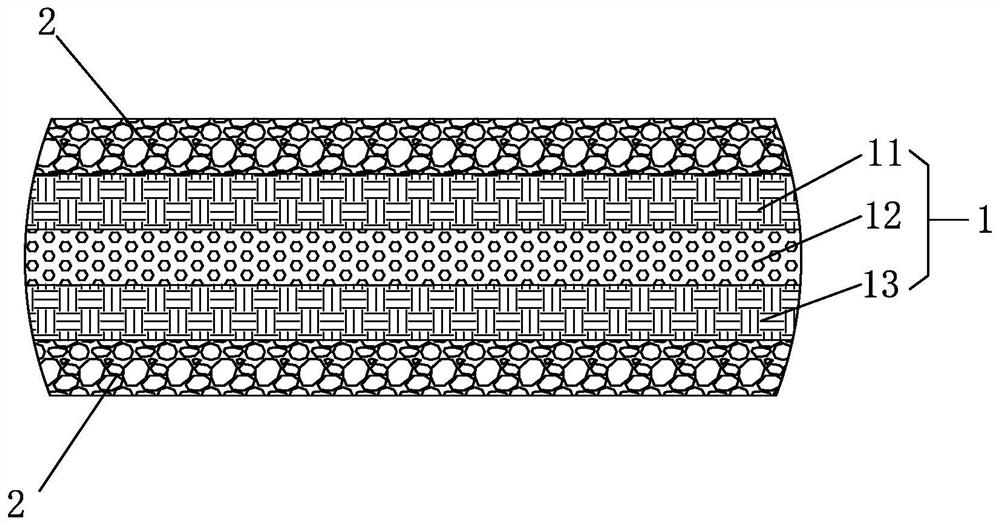

Image

Examples

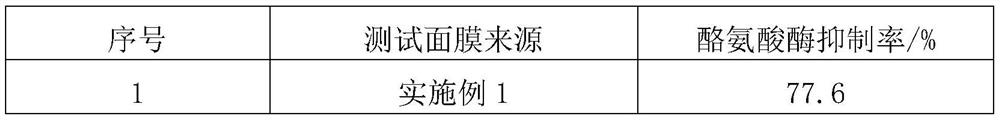

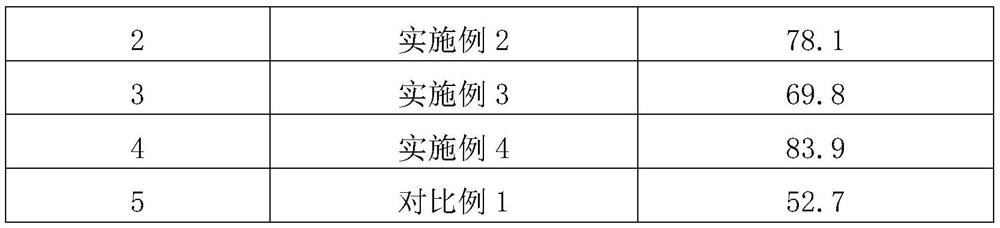

Embodiment 1

[0040] S1: Select complete, mildew-free, and insect-free plump camellia fruits to prepare camellia berries, clean the camellia berries, dry them in an oven at 60°C for 24 hours, and crush them to below 100 mesh to obtain camellia berries powder. 50% edible ethanol solution, ultrasonic extraction at 70°C for 1 hour, and repeated extraction three times. The extract was centrifuged at 4000r / min for 10min, filtered to obtain anthocyanin extract, separated and purified by macroporous resin, and gradient eluted with different concentrations of edible ethanol to obtain anthocyanin solution, which was prepared by low-temperature concentration to prepare a concentrated solution for future use ;

[0041] S2. Prepare the following raw materials according to mass percentage: 1.0% camellia anthocyanin concentrate, 2% camellia flower extract, 0.5% squalane, 0.01% nicotinamide, 0.2% sodium hyaluronate, 2% butanediol, Trehalose 0.5%, glycerin 0.5%, phenoxyethanol 0.1%, ethylhexylglycerin 0.8...

Embodiment 2

[0045] S1: Select complete, mildew-free, and pest-free plump camellia fruits to prepare camellia berries, clean the camellia berries, dry them in an oven at 60°C for 23 hours, and crush them to below 100 mesh to obtain camellia berries powder. 50% edible ethanol solution, ultrasonic extraction at 70°C for 1 hour, and repeated extraction three times. The extract was centrifuged at 4000r / min for 10min, filtered to obtain anthocyanin extract, separated and purified by macroporous resin, and gradient eluted with different concentrations of edible ethanol to obtain anthocyanin solution, which was prepared by low-temperature concentration to prepare a concentrated solution for future use ;

[0046] S2. Prepare the following raw materials according to mass percentage: 1.0% camellia anthocyanin concentrate, 5% camellia flower extract, 0.5% squalane, 0.02% nicotinamide, 0.4% sodium hyaluronate, 2.5% butanediol, Trehalose 0.5%, glycerin 0.5%, phenoxyethanol 0.15%, ethylhexylglycerin 0....

Embodiment 3

[0050] S1: Select complete, mildew-free, and pest-free plump camellia fruits to prepare camellia berries, clean the camellia berries, dry them in an oven at 55°C for 25 hours, and crush them to below 100 mesh to obtain camellia berries powder, add 50% edible ethanol solution, ultrasonic extraction at 70°C for 1 hour, and repeated extraction three times. The extract was centrifuged at 4000r / min for 10min, filtered to obtain anthocyanin extract, separated and purified by macroporous resin, and gradient eluted with different concentrations of edible ethanol to obtain anthocyanin solution, which was prepared by low-temperature concentration to prepare a concentrated solution for future use ;

[0051] S2. Prepare the following raw materials according to the mass percentage: 0.5% camellia anthocyanin concentrate, 2% camellia flower extract, 0.7% squalane, 0.02% nicotinamide, 0.5% sodium hyaluronate, 2.5% butanediol, Trehalose 0.5%, glycerin 0.5%, phenoxyethanol 0.15%, ethylhexylgly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com