Fluopyram and fluazinam compounded granule and preparation process thereof

A technology of fluazinam complex and fluopyram, which is applied in the direction of fungicides, biocides, biocides, etc., and can solve problems such as clay particles and difficulty in drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation of 80% functional master powder is as follows:

[0053] Active ingredient water reducer Dispersant lubricant binder Silica Peptone total 96% Fluopyram 834g 30g 40g 10g 20g 20g make up 1000g 98% Fluazinam 820g 30g 40g 10g 20g 20g make up 1000g

[0054] The components of functional adhesive paste are as follows:

[0055] sucrose starch Warning color water 200 100g 20g 630g

[0056] The fluopyram and fluazinam compound granules with different content ratios are designed to be used in the prevention and control of peanut root-knot nematode disease. The specific implementation cases of the granules are as follows:

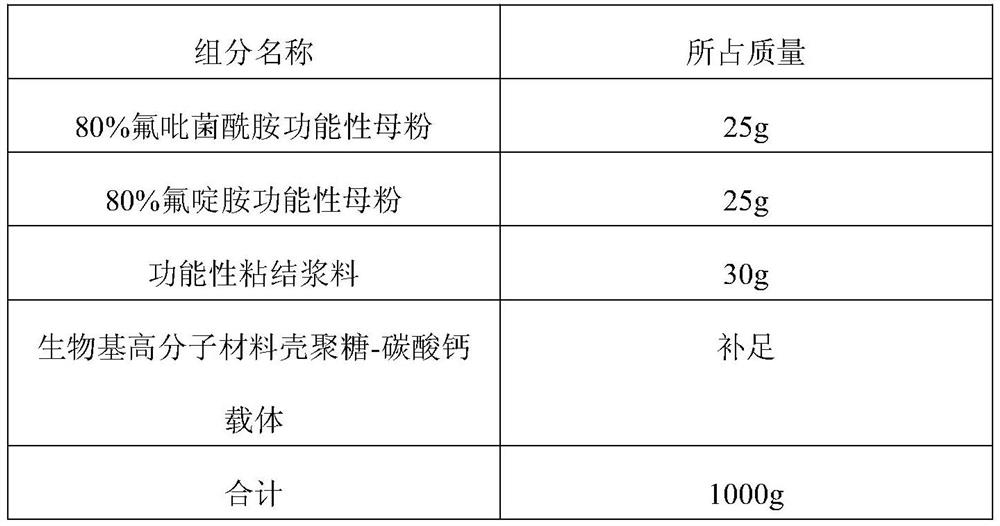

Embodiment 1

[0058] A compound granule containing fluopyram and fluazinam, the components and the mass occupied are:

[0059]

[0060] The operation steps are: add the bio-based polymer material chitosan-calcium carbonate carrier particles that meet the requirements into the coating granulator according to the mass ratio, add 10g of functional bonding slurry under stirring, and stir to the surface of the carrier Wet evenly, then add 8.3g fluopyram master powder and 8.3g fluazinam functional master powder, mix evenly on the surface of the carrier to form a drug film; add 10g functional adhesive slurry and 8.3g fluopyram under stirring Functional master powder, 8.3 g of fluazinam functional master powder, stir and mix evenly, add 10 g of the third adhesive slurry and the remaining fluopyram functional master powder and fluazinam functional master powder, stir and mix evenly , and the finished product of dry-coated granules is obtained.

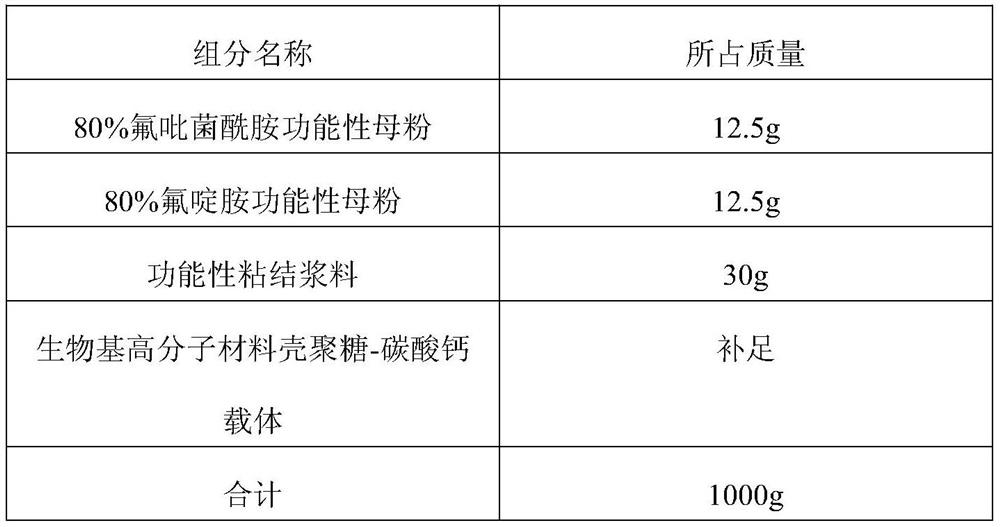

Embodiment 2

[0062] A compound granule containing fluopyram and fluazinam, the components and the mass occupied are:

[0063]

[0064] The operation steps are: add the bio-based polymer material chitosan-calcium carbonate carrier particles that meet the requirements into the coating granulator according to the mass ratio, add 10g of functional bonding slurry under stirring, and stir to the surface of the carrier Wet evenly, then add 4.2g fluopyram master powder and 4.2g fluopyram functional master powder, and mix evenly on the surface of the carrier to form a drug film; add 10g functional adhesive slurry and 4.2g fluopyram under stirring Functional master powder, 4.2 g of fluazinam functional master powder, stir and mix evenly, add 10 g of the third adhesive slurry and the remaining fluopyram functional master powder and fluazinam functional master powder, stir and mix evenly , and the finished product of dry-coated granules is obtained.

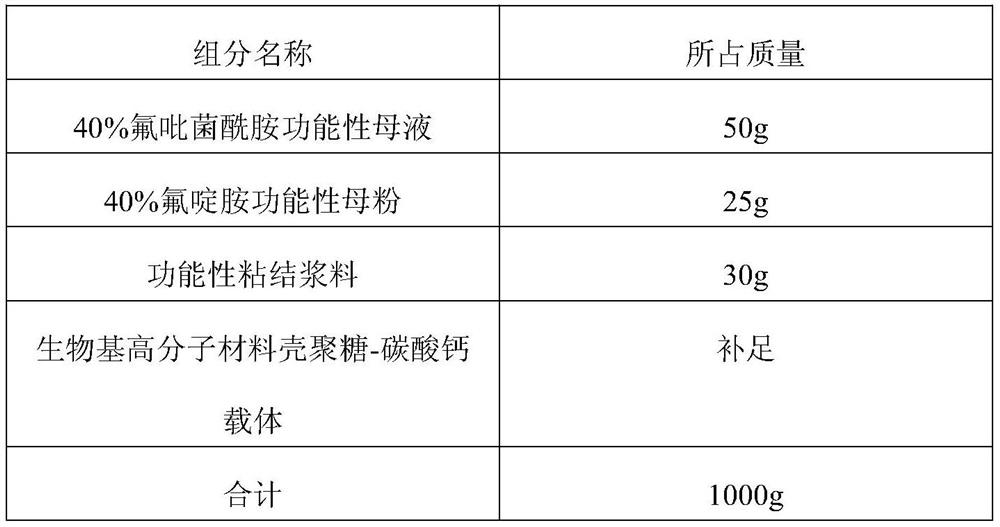

[0065] 2. A functional mother liquor containin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com