Injection molding assembly method of secondary battery top cover assembly and top cover assembly

A technology of secondary battery and assembly method, which is applied in the direction of battery cover/end cover, small-sized battery/battery pack, battery, etc. Affect the assembly efficiency of secondary batteries and other issues, and achieve the effects of increasing bonding stability, reducing production costs, and increasing fixing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended purpose, the specific implementation modes of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

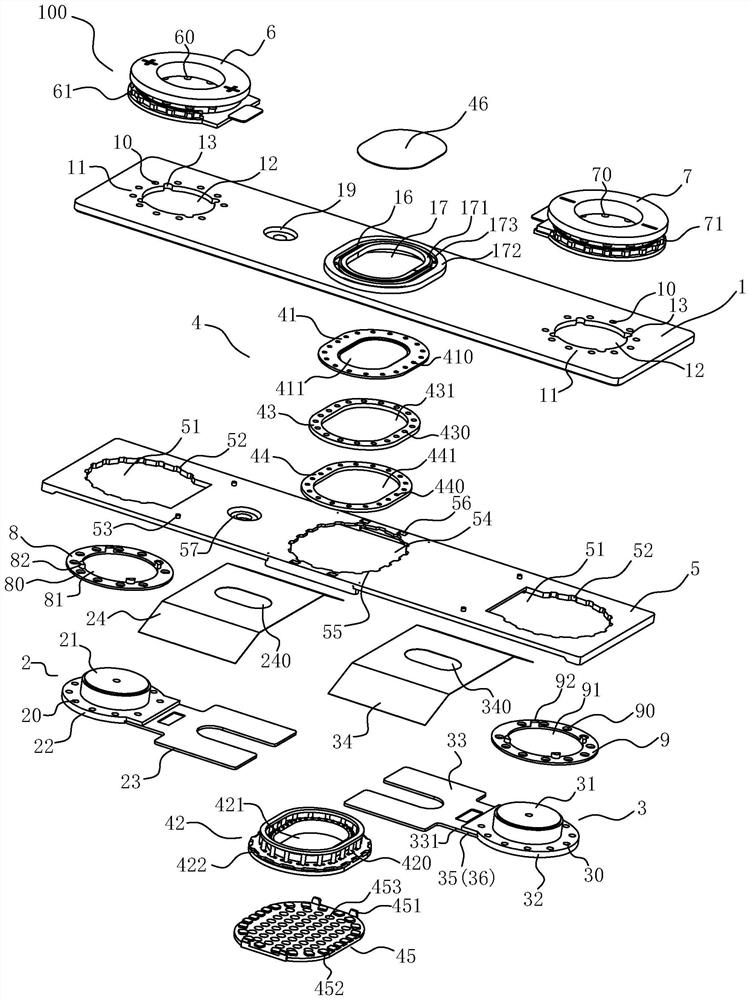

[0056] Please refer to Figure 1 to Figure 5 , an embodiment of the present invention provides an injection molding assembly method for a secondary battery top cover assembly 100, including the following steps:

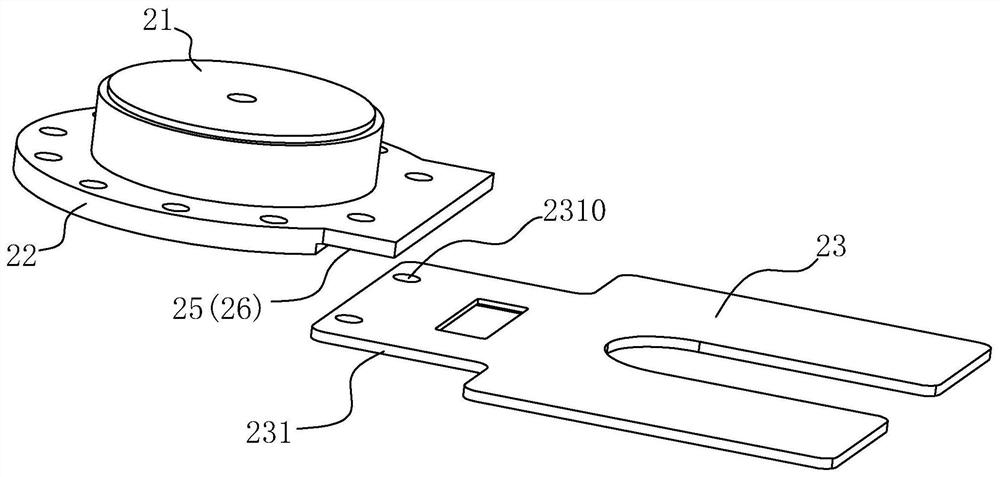

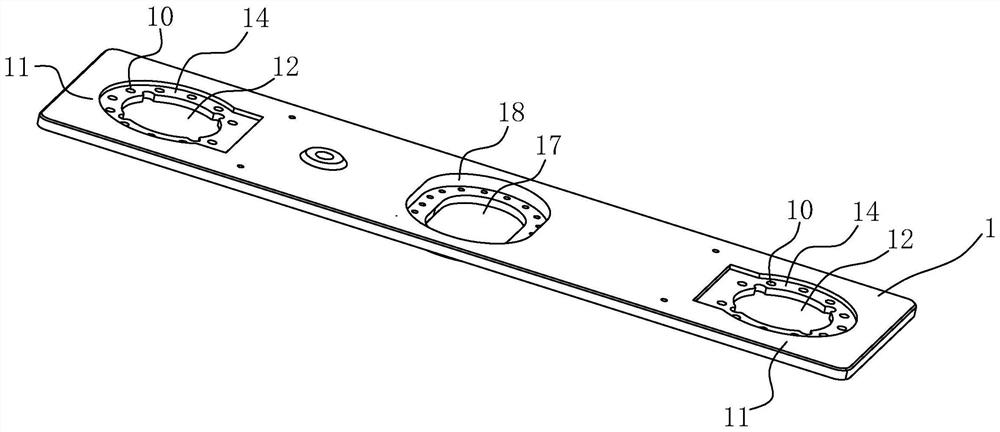

[0057] (1) Prepare the following components: top cover plate 1, first electrode terminal 2, second electrode terminal 3, first seal 8, second seal 9, explosion-proof structure 4, lower insulating bracket 5, first connecting piece 23 , the second connecting sheet 33, the first insulating film 24 and the second insulating film 34;

[0058] (2) Assembling the lower insulating bracket 5 on the bottom surface of the top cover plate 1;

[0059] (3) Ultrasonic welding the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com