Equipment state prediction method and system based on multi-dimensional data fusion

A technology of device status and multi-dimensional data, applied in prediction, data processing applications, instruments, etc., to increase computing efficiency, save communication overhead, and improve regression performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

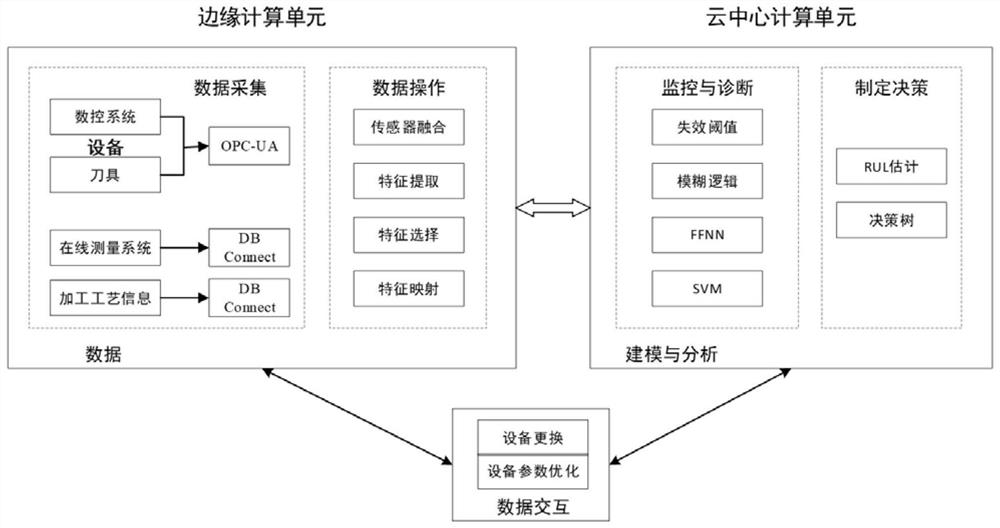

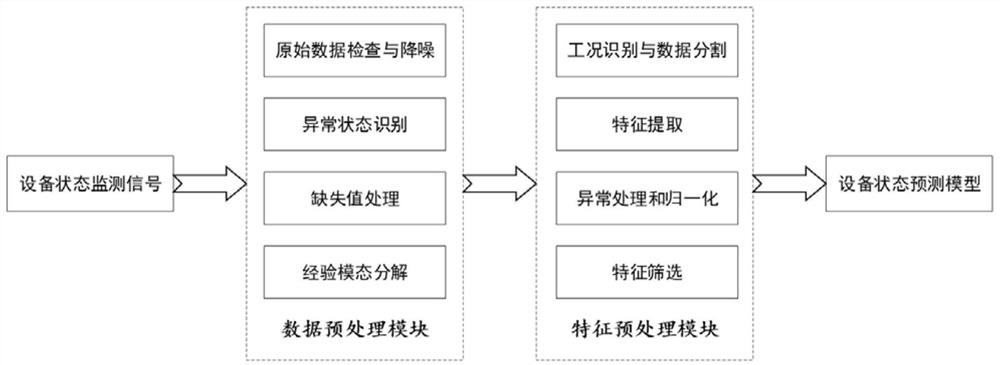

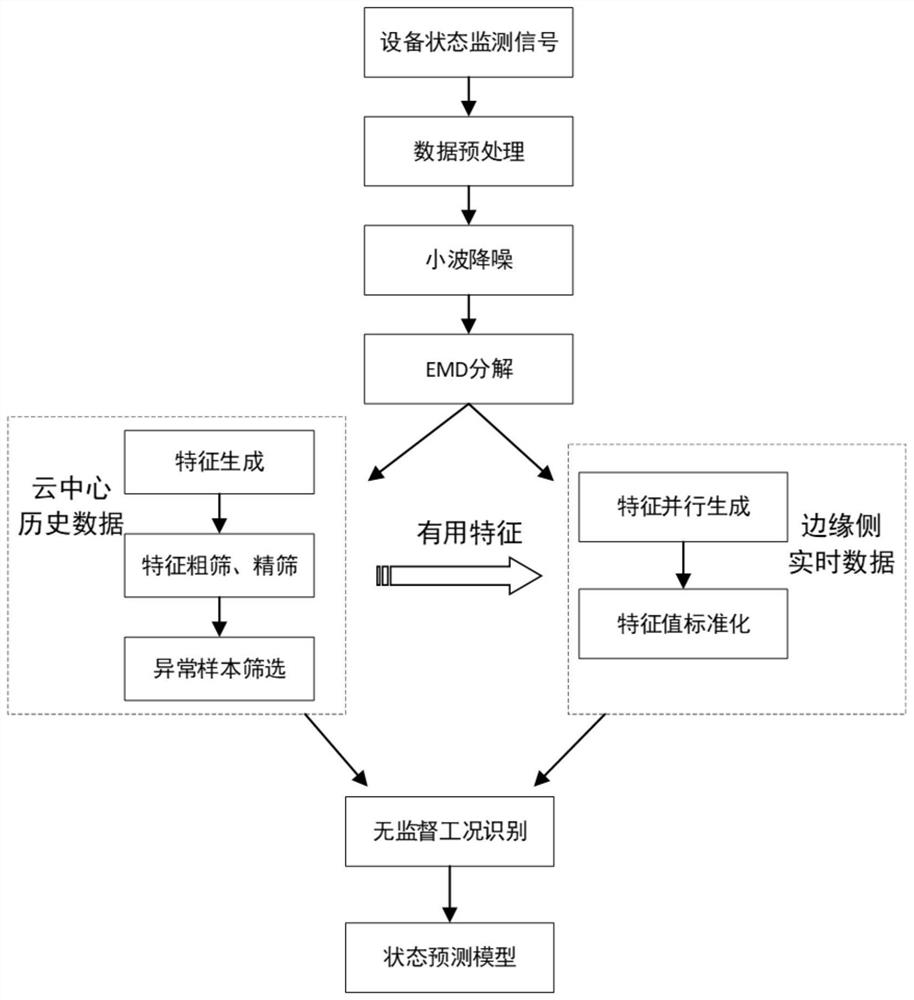

[0050] The equipment used in this example is a CNC machine tool and its cutting tools in the field of cutting processing. The whole system architecture diagram is as follows figure 1 As shown, model learning and feature processing are performed in the industrial cloud central computing unit, and signal acquisition and data processing are performed in the edge computing unit, which saves communication overhead to the greatest extent and improves the performance of the prediction system. The algorithm framework of the equipment (NC machine tool and its tool) status and its remaining life prediction system based on multi-dimensional data fusion is as follows: figure 2 As shown, the corresponding prediction system algorithm flow chart is as follows image 3 shown.

[0051] The specific steps of the equipment status and its remaining life prediction method are as follows:

[0052] The first step, training data collection

[0053] Step 1.1. Set the sampling frequency of the vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com