Valve body structure optimization method based on eddy current distribution

An optimization method and technology of the valve body, applied in the direction of valve shell structure, design optimization/simulation, valve device, etc., can solve problems such as the optimization method of valve body structure without vortex distribution, avoid theoretical calculation and experimental correction, and improve fluid flow Flow, improve the effect of the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

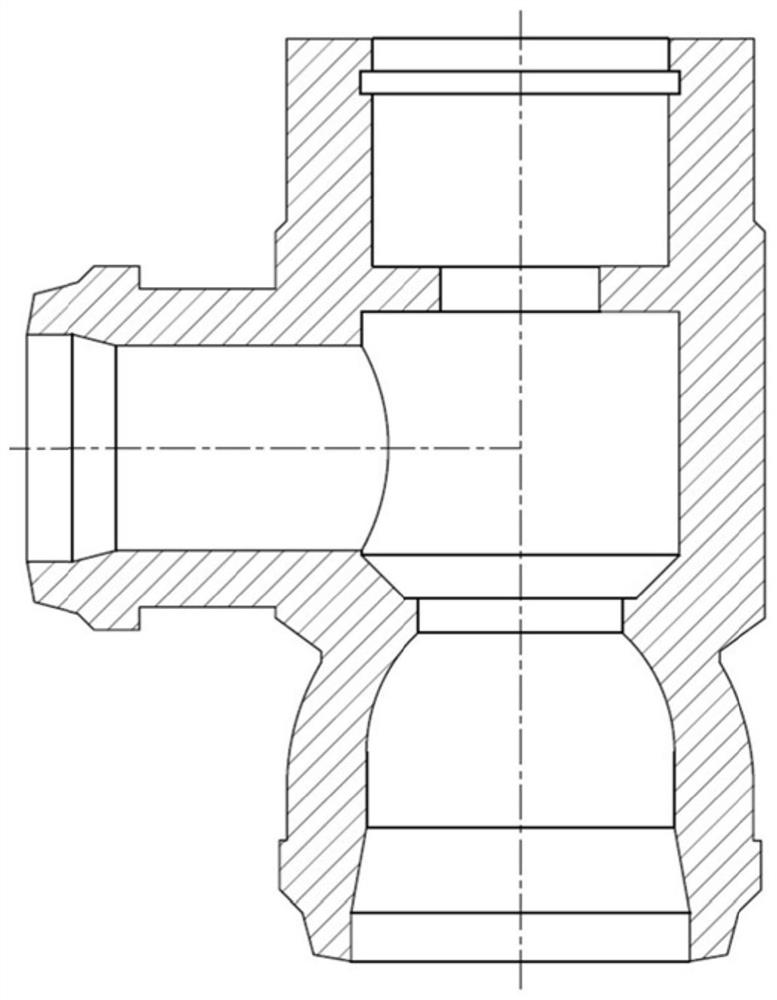

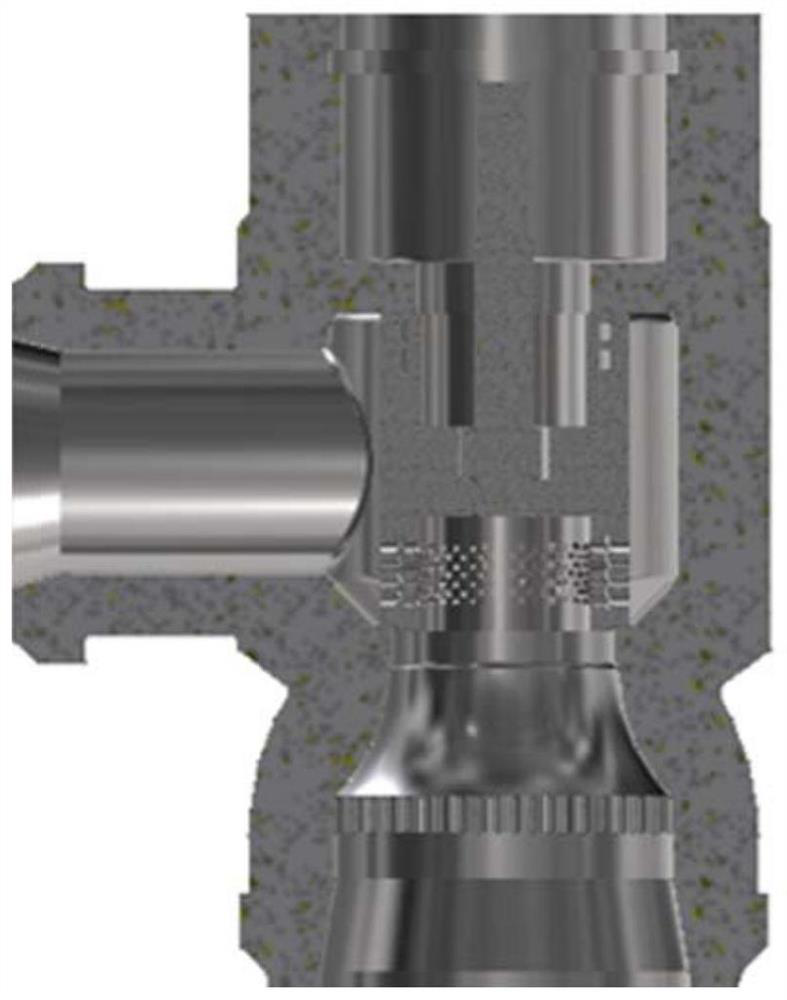

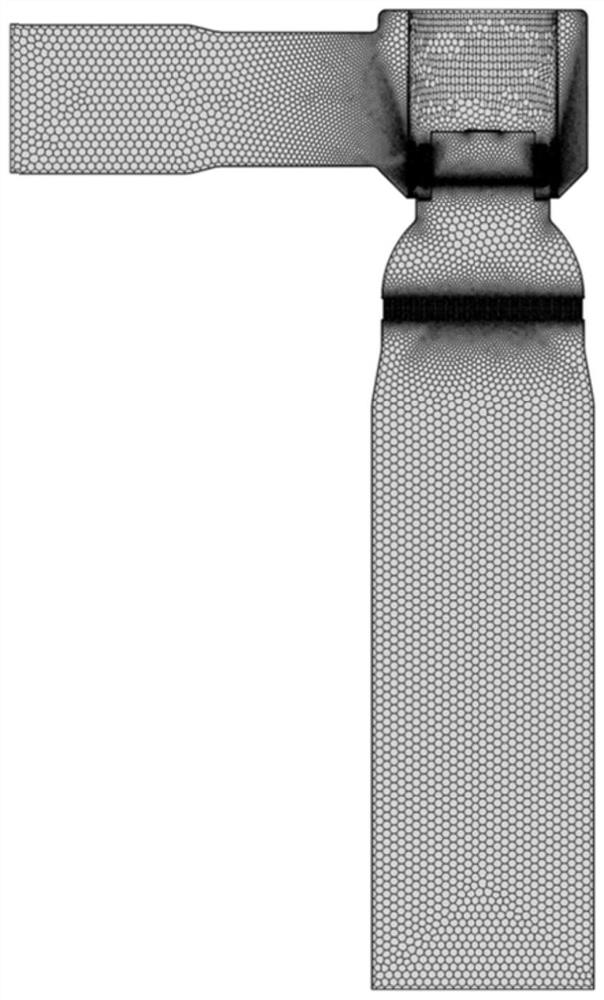

[0087] S1: if figure 1 Shown is a two-dimensional drawing of the valve body of the pressure reducing valve to be optimized. According to the design documents of the valve, the three-dimensional structural model of the valve is constructed by three-dimensional modeling software, and the three-dimensional structural model of the pressure reducing valve is as follows: figure 2 shown. Depend on figure 2 It can be seen that the structure of the valve body is symmetrical about the longitudinal section plane of the valve body, so a 1 / 2 valve body model symmetrical about the section plane can be established. In the three-dimensional modeling software, establish the solid model of the pressure reducing valve. According to the internal flow channel of the valve entity model, the internal flow channel model of the valve is extracted. Since the three-dimensional structure model of the valve in this embodiment is 1 / 2 of the valve model relative to the longitudinal section, that is, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com