A geopolymer grouting material based on incineration fly ash and its preparation method

A technology for incinerating fly ash and grouting materials, applied in cement production, etc., to achieve the effect of convenient transportation and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

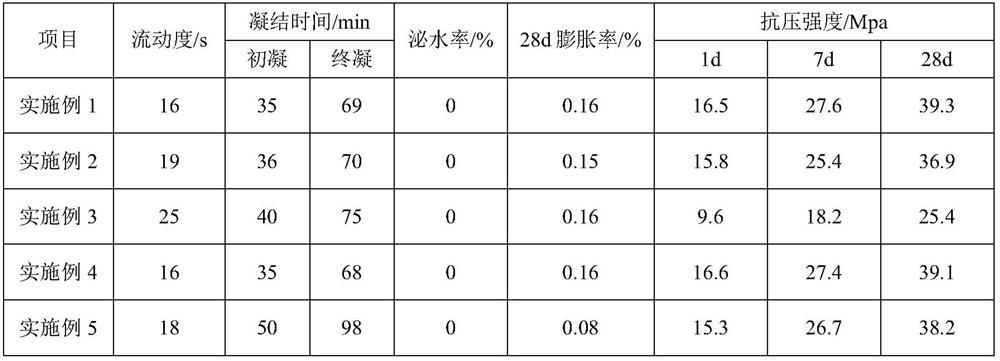

Examples

Embodiment 1

[0043] (1) Straw - 30 parts of urban waste incineration fly ash, 16 parts of fly ash, 10 parts of metakaolin, 8 parts of silica fume, 5 parts of calcined gypsum, 5 parts of bauxite, 15 parts of soda lime, and 2 parts of calcium aluminate , 2 parts of sodium aluminate, 2 parts of sodium phosphate, 0.8 parts of polycarboxylate superplasticizer, 0.1 part of hydroxypropyl methylcellulose ether, 0.1 part of polyether defoamer, 0.1 part of polyether air-entraining agent, plastic expansion 0.1 part of agent, 2 parts of polyaluminum chloride, 1.8 parts of ethylenediaminetetraacetic acid (EDTA), and the ratio of water to material is 0.35.

[0044] (2) Accurately weigh 2500g of the dry mixture according to the mixing ratio of (1), pour the dry mixture into the cement slurry high-speed mixer, and stir the dry mixture for more than 2 minutes at a speed of 500r / min until it is uniform; Weigh water at a water-to-material ratio of 0.35, first add 80% to the high-speed mixer, and stir for 1 m...

Embodiment 2

[0046] (1) Straw - 40 parts of urban waste incineration fly ash, 6 parts of fly ash, 10 parts of metakaolin, 8 parts of silica fume, 5 parts of calcined gypsum, 5 parts of bauxite, 15 parts of soda lime, 2 parts of calcium aluminate , 2 parts of sodium aluminate, 2 parts of sodium phosphate, 0.8 parts of polycarboxylate superplasticizer, 0.1 part of hydroxypropyl methylcellulose ether, 0.1 part of polyether defoamer, 0.1 part of polyether air-entraining agent, plastic expansion 0.1 part of agent, 2 parts of polyaluminum chloride, 1.8 parts of ethylenediaminetetraacetic acid (EDTA), and the ratio of water to material is 0.35.

[0047] (2) Accurately weigh 2500g of the dry mixture according to the mixing ratio of (1), pour the dry mixture into the cement slurry high-speed mixer, and stir the dry mixture for more than 2 minutes at a speed of 500r / min until it is uniform; Weigh water at a water-to-material ratio of 0.35, first add 80% to the high-speed mixer, and stir for 1 minute...

Embodiment 3

[0049] (1) Straw - 50 parts of urban waste incineration fly ash, 10 parts of metakaolin, 4 parts of silica fume, 5 parts of calcined gypsum, 5 parts of bauxite, 15 parts of soda lime, 2 parts of calcium aluminate, and 2 parts of sodium aluminate , 2 parts of sodium phosphate, 0.8 parts of polycarboxylate superplasticizer, 0.1 part of hydroxypropyl methylcellulose ether, 0.1 part of polyether defoamer, 0.1 part of polyether air-entraining agent, 0.1 part of plastic expansion agent, polymerized chlorine 2 parts of aluminum chloride, 1.8 parts of ethylenediaminetetraacetic acid (EDTA), and the ratio of water to material is 0.35.

[0050] (2) Accurately weigh 2500g of the dry mixture according to the mixing ratio of (1), pour the dry mixture into the cement slurry high-speed mixer, and stir the dry mixture for more than 2 minutes at a speed of 500r / min until it is uniform; Weigh water at a water-to-material ratio of 0.35, first add 80% to the high-speed mixer, and stir for 1 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com