Electronic ceramic material surface wet grinding equipment and grinding method thereof

A technology of electronic ceramics and wet grinding, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc., which can solve the problems of damage to electronic ceramic materials, achieve the effect of improving grinding efficiency and suppressing the generation of high-temperature dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

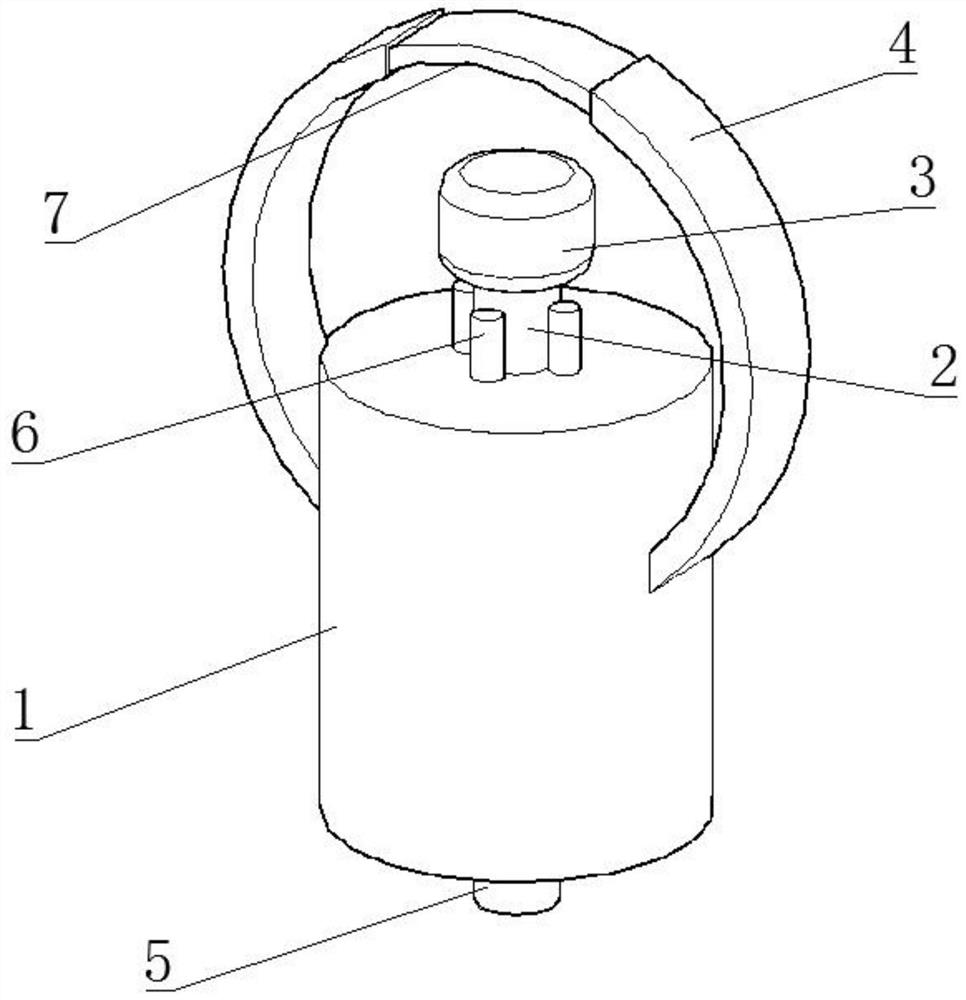

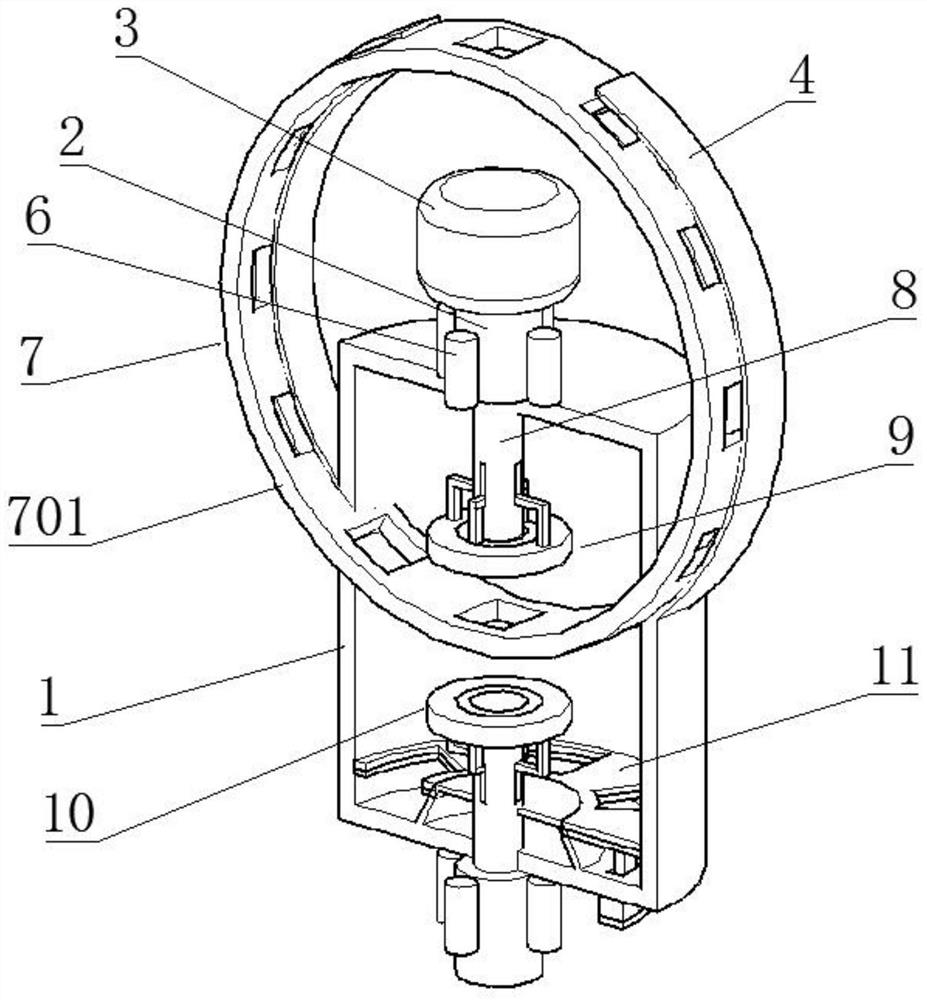

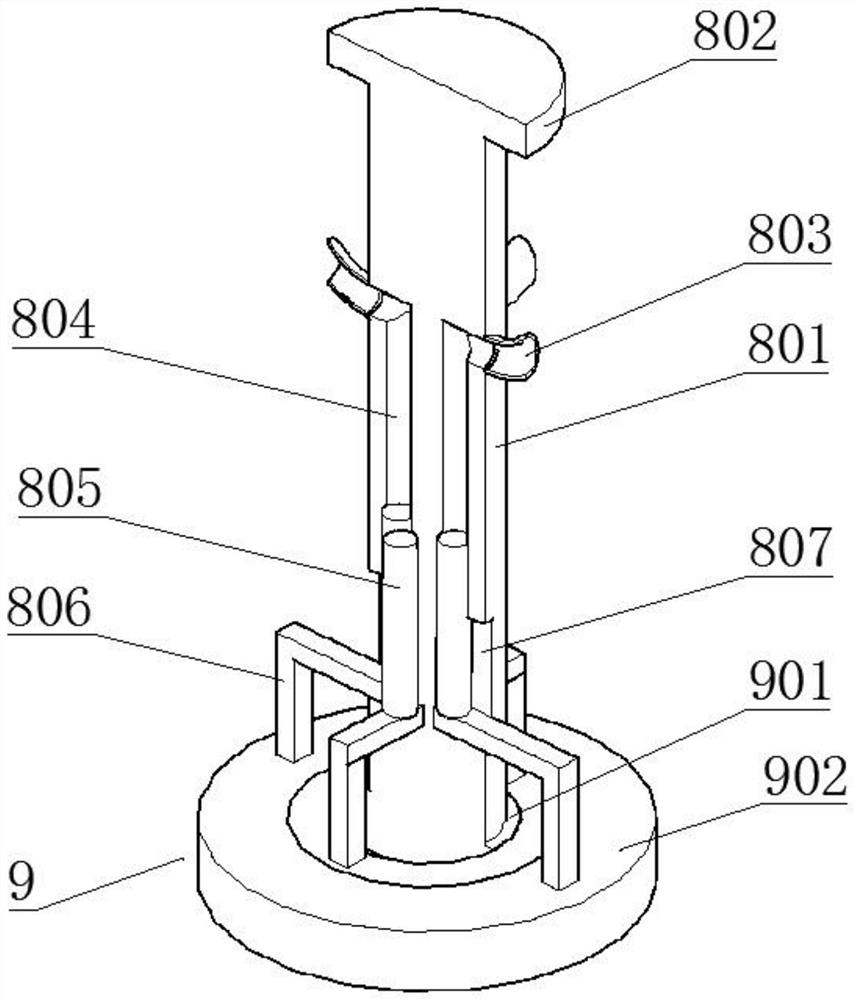

[0031] Such as figure 1 As shown, the electronic ceramic material surface wet grinding equipment includes a bucket 1, a support mechanism 10 is arranged in the bucket 1, a grinding mechanism 8 is arranged on the top of the support mechanism 10, and it is located between the support mechanism 10 and the grinding mechanism 8 A feeding mechanism 7 is provided, and the feeding mechanism 7 penetrates the water bucket 1 and is slidably connected with the water bucket 1. The grinding mechanism 8 includes a grinding shaft 801 that is slidably connected with the top of the water bucket 1, and the grinding shaft 801 is fixedly connected with the top of the water bucket 1. The first cylinder 2 is slidingly connected, the top of the cylinder is fixedly connected with a motor 3, the output shaft of the motor 3 is radially fixedly connected with the grinding shaft 801, the first cylinder 2 communicates with the second cylinder 5 at the bottom of the bucket 1, One end of the grinding shaft 8...

Embodiment 2

[0034] Such as Figure 1-3As shown, the electronic ceramic material surface wet grinding equipment includes a bucket 1, a support mechanism 10 is arranged in the bucket 1, a grinding mechanism 8 is arranged on the top of the support mechanism 10, and it is located between the support mechanism 10 and the grinding mechanism 8 A feeding mechanism 7 is provided, and the feeding mechanism 7 penetrates the water bucket 1 and is slidably connected with the water bucket 1. The grinding mechanism 8 includes a grinding shaft 801 that is slidably connected with the top of the water bucket 1, and the grinding shaft 801 is fixedly connected with the top of the water bucket 1. The first cylinder 2 is slidingly connected, the top of the cylinder is fixedly connected with a motor 3, the output shaft of the motor 3 is radially fixedly connected with the grinding shaft 801, the first cylinder 2 communicates with the second cylinder 5 at the bottom of the bucket 1, One end of the grinding shaft...

Embodiment 3

[0037] Such as Figure 1-5 As shown, the electronic ceramic material surface wet grinding equipment includes a bucket 1, a support mechanism 10 is arranged in the bucket 1, a grinding mechanism 8 is arranged on the top of the support mechanism 10, and it is located between the support mechanism 10 and the grinding mechanism 8 A feeding mechanism 7 is provided, and the feeding mechanism 7 penetrates the water bucket 1 and is slidably connected with the water bucket 1. The grinding mechanism 8 includes a grinding shaft 801 that is slidably connected with the top of the water bucket 1, and the grinding shaft 801 is fixedly connected with the top of the water bucket 1. The first cylinder 2 is slidingly connected, the top of the cylinder is fixedly connected with a motor 3, the output shaft of the motor 3 is radially fixedly connected with the grinding shaft 801, the first cylinder 2 communicates with the second cylinder 5 at the bottom of the bucket 1, One end of the grinding shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com