High-fluorine-containing C9 resin hydrogenation catalyst and preparation method and application thereof

A hydrogenation catalyst and catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of low defluorination accuracy and complicated process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

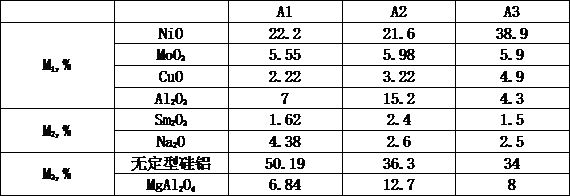

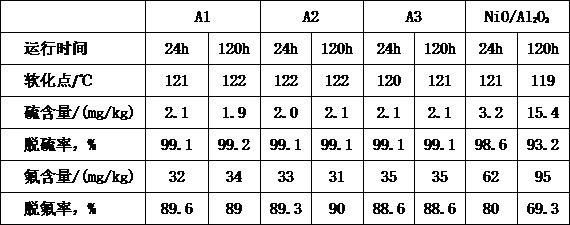

Embodiment 1

[0026]86.1 g of nickel nitrate, 3.8 g of copper chloride and 23.5 g of aluminum sulfate were added to water into solution I, then 0.5 mol / L of sodium hydroxide solution droplets were added to the solution I, and the reaction temperature was 65 ° C, and the system pH was 9 After the precipitation was completed, the constant temperature was stirred for 4 h, and the obtained slurry was treated. A 6.9 g of lymolybdate was dissolved in water, and 2 g of sodium dodecyl sulfonate was added to a solution II, stirred to 80 ° C, and then the above-mentioned slurry was added to the solution II, and the reaction was refluxed at 120 ° C for 4h. The resulting product was filtered, washed, dried to give a component M1Pretty precursor.

[0027]24 g of sodium bleed sodium, 100 g sodium silicate (25% SiO2The content), 33.5 g of aluminum sulfate each formulated into a solution, and the reaction temperature was added to the reaction vessel, the reaction temperature was 35 ° C, the pH was 6.5, and the re...

Embodiment 2

[0030]37.3 g of nickel chloride, 6.7 g of copper and 111.8 g of aluminum nitrate were added to water into a solution I, then 0.6 mol / L of ammonia solution droplets were added to the solution I, and the reaction temperature was 50 ° C, the system pH was 10, precipitation After completion, the constant temperature was stirred for 3 h, and the obtained slurry was treated. Ammonium 7.3 g of ketan-molybdate was dissolved in water, and a solution of 2.5 g of cencetal trimethyl bromide was added to a solution II, stirred to 50 ° C, and then the above obtained slurry was added to the solution II, at 80 ° C at 80 ° C The reflux reaction was 3 h, and the resulting product was filtered, washed, dried to give a component M1Pretty precursor.

[0031]32.2 g of aluminate, 40 g sodium silicate (25% SiO2The content), 67 g of aluminum sulfate each substrate into a solution, and the reaction temperature was added to the reaction vessel, the reaction temperature was 20 ° C, the pH was 9.5, and the react...

Embodiment 3

[0034]151 g of nickel nickel nickel nickel nickel nitrate, 31.6 g of aluminum nitrate was added to water into a solution I, then 0.5 mol / L of sodium hydroxide solution droplets were added to the solution I, control the reaction temperature of 80 ° C, and the system pH is 9, precipitation After completion, the constant temperature was stirred for 5 h, and the obtained slurry was treated. 6.8 g of four molybdate is dissolved in water, and 2 g of sodium dodecyl sulfonate is added to solution II, stirred to 65 ° C, and then adding the slurry to the solution II, reflux reaction at 100 ° C for 5 h, The resulting product was filtered, washed, dried to give a component M1Pretty precursor.

[0035]Put 16 g of aluminate, 40 g sodium silicate (25% SiO2The content), 47 g of aluminum aluminum sulfate each formulated into a solution, and the reaction temperature was added to the reaction vessel, and the reaction temperature was 50 ° C, the pH was 8, and the reaction was 2.5 h, then heated to 90 ° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com