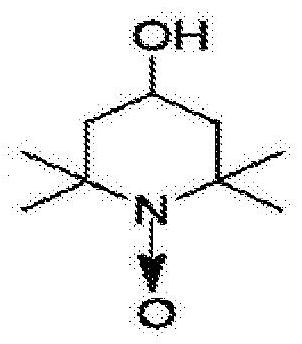

Catalyst, preparation method thereof and use thereof in production of nitroxide radical piperidinols

A nitroxide radical piperidinol and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of difficult wastewater treatment, low conversion rate of raw materials, and low catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of catalyst of the present invention comprises the following steps:

[0024] 1. Provide a mixed solution of tetraethyl silicate and water

[0025] The mass ratio of tetraethyl silicate and water in the mixed solution of tetraethyl silicate and water of the present invention is between 0.05~0.5, preferably between 0.08~0.46, more preferably between 0.12~0.42, preferably between Between 0.16 and 0.38, preferably between 0.20 and 0.32, preferably between 0.25 and 0.28.

[0026] The method of the present invention includes the step of adjusting the pH value of the mixed solution of tetraethyl silicate and water to 10.0-12.0, preferably to 10.5-11.5. The base used to adjust the pH is not particularly limited, and may be a conventional base known in the art, such as alkali metal hydroxide, ammonia water, organic base and the like. Ammonia is preferably used.

[0027] The method of the present invention also includes the step of stirring the mixed sol...

Embodiment 1

[0047] 1. Synthesis of catalyst:

[0048] Dissolve 20.833 grams of tetraethyl silicate in 100 grams of water at 25°C, then add dropwise 25% ammonia water to a pH value of 11.0, then stir at room temperature for 4 hours, tetraethyl silicate slowly hydrolyzes, and the solution Gradually turns milky white. Mix 0.534 grams of tetraethyl titanate and 5.34 grams of absolute ethanol evenly, and then slowly add it dropwise into the solution containing silicon dioxide, control the temperature during the dropwise addition at 20-30°C, and continue stirring for 4 hours after the dropwise addition is completed , and then the slurry was filtered, washed three times with 100ml of distilled water, dried at 120°C for 12 hours, and then calcined at 500°C for 4 hours to obtain a titanium-containing solid catalyst. The element composition of the solid catalyst was analyzed by an inductively coupled atomic emission spectrometer (ICP-AES). The content of titanium in the solid catalyst was 2% by we...

Embodiment 2

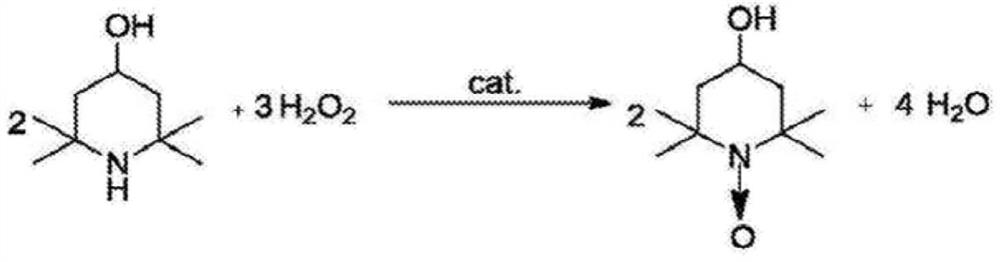

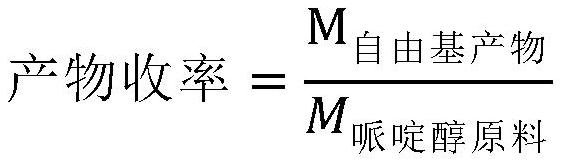

[0056] Add 157 grams of 2,2,6,6-tetramethyl-4-hydroxypiperidine, 121.5 grams of 28% hydrogen peroxide in a 2L three-necked flask as raw material, 1.57 grams of titanium-containing solid catalyst (same as Example 1), to 786 grams of water was used as a solvent, the reaction temperature was 80° C., and the reaction time was 3 hours. After the reaction, the catalyst was filtered out, all the solvent was evaporated, and the remaining organic phase was cooled, crystallized, and filtered to obtain 2,2,6,6-tetramethyl-4-hydroxypiperidine nitroxide free radical, which was obtained by Gas chromatography quantitative analysis showed that the product weight was 132.6 grams, the product yield was 84.3%, and the hydrogen peroxide effective utilization rate was 84.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com