Preparation method of valsartan particles

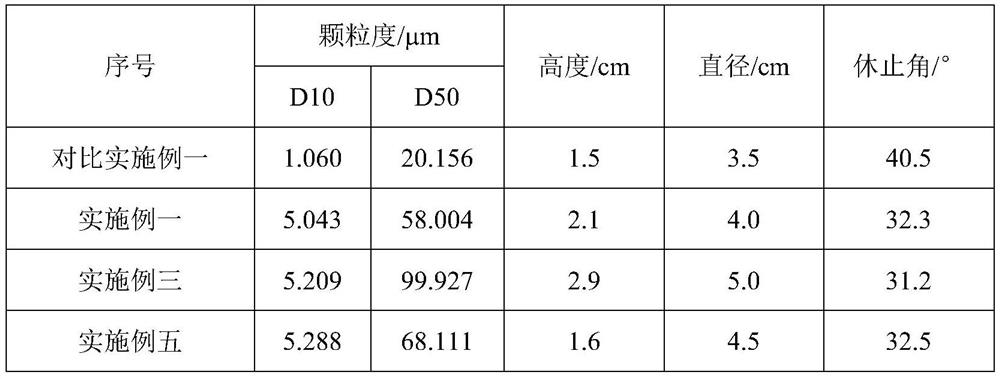

A technology of valsartan granules and valsartan, applied in the field of medicine and chemical industry, can solve the problems of poor fluidity, poor uniformity, uneven mixing, etc., and achieve the effects of avoiding the introduction of risks, improving uniformity and improving fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Put 400 kg of crude valsartan and 3200 liters of ethyl acetate into the reaction kettle, heat up to 50°C, and stir until it dissolves. Slowly lower the temperature in the reactor to 39°C, keep it warm for 2 hours, then slowly drop the temperature to 0°C, keep it warm for 2 hours to crystallize. After the crystallization operation is completed, the feed liquid is put into a centrifuge for rejection filtration, and the amount of the filtered mother liquor is controlled to 3000 liters to obtain a wet product of valsartan, and the mass content of ethyl acetate in the wet product is detected to be 30%.

[0027] Install the FZB pulverizer with a sieve with an aperture of 1.0cm, adjust the speed of the pulverizer to 1950rpm, tie a polyethylene bag on the discharge port, start the pulverizer, and slowly add the above-mentioned wet product of valsartan into the working chamber until the processing is completed ; Place the pulverized product in a double-cone vacuum dryer and dry ...

Embodiment 2

[0030] The steps of valsartan recrystallization are the same as in Example 1. After the crystallization operation is completed, the feed liquid is put into a centrifuge for rejection filtration, and the amount of the filtered mother liquor is controlled to 3000 liters to obtain a wet product of valsartan, and the mass content of ethyl acetate in the wet product is detected to be 30%.

[0031] Install the FZB pulverizer with a sieve with an aperture of 2.0cm, adjust the speed of the pulverizer to 3600rpm, tie a polyethylene bag on the discharge port, start the pulverizer, and slowly add the above-mentioned wet product of valsartan into the working chamber until the processing is completed ; Place the pulverized product in a double-cone vacuum dryer and dry it at 55-60°C for 12 hours;

[0032] Install the CFS pulverizer with a sieve with an aperture of 1.6mm, adjust the speed of the pulverizer to 5000rpm, pulverize the dried product, and detect the particle size. The D10 is 4.48...

Embodiment 3

[0034] The steps of valsartan recrystallization are the same as in Example 1. After the crystallization operation is finished, the feed liquid is put into a centrifuge for rejection filtration, and the amount of the filtered mother liquor is controlled to 2900 liters to obtain a wet product of valsartan, and the mass content of ethyl acetate in the wet product is detected to be 45%.

[0035] Install the FZB type pulverizer with a screen with an aperture of 1.0cm, adjust the speed of the pulverizer to 2200rpm, tie a polyethylene bag on the discharge port, start the pulverizer, and slowly add the above-mentioned wet product of valsartan into the working chamber until the processing is completed ; Place the pulverized product in a double-cone vacuum dryer, and dry it at 55-60°C for 13 hours;

[0036] Install the CFS type pulverizer with a sieve with an aperture of 1.2 mm, adjust the speed of the pulverizer to 2000 rpm, and pulverize the dried product. The particle size is detect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com