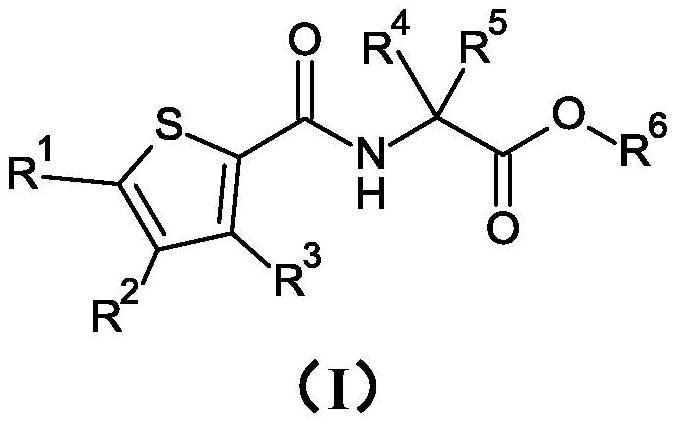

Substituted thiophenecarboxamides and analogues as antibacterials agents

A compound, the technology of haloalkyl, applied in the field of substituted thiophene carboxamide and its analogues, can solve the problem of not providing etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

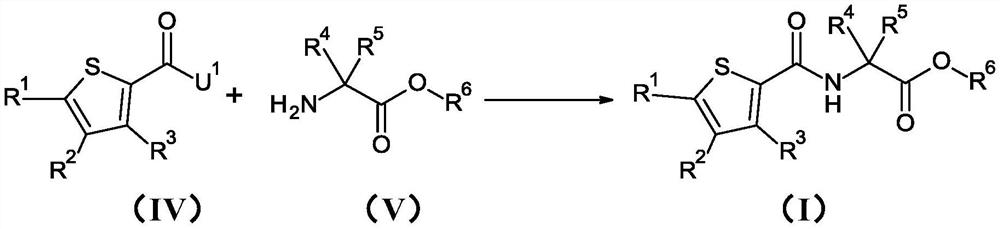

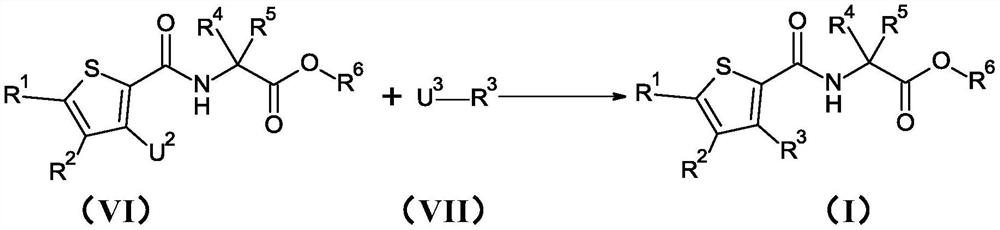

Method used

Image

Examples

preparation Embodiment 1

[0352] Preparation Example 1 : Preparation of N-[(4,5-dichloro-3-methyl-2-thienyl)carbonyl]glycine ethyl ester (Compound I.03)

[0353] step 1 : Preparation of methyl 3-amino-4,5-dichlorothiophene-2-carboxylate

[0354] 1.35 g (5.04 mmol) of methyl 3-acetamido-4,5-dichlorothiophene-2-carboxylate was dissolved in a mixture of 2.1 mL (25.18 mmol) of 37% (w / w) aqueous hydrochloric acid and 8.2 mL of methanol middle. The mixture was heated at 75°C for 3 hours. The cooled reaction mixture was treated with 30% (w / w) sodium hydroxide solution at 0°C. The resulting solution was extracted with ethyl acetate. The combined organic layers were dried over magnesium sulfate, filtered and concentrated under reduced pressure to give 812 mg (98% purity, 70% yield) of 3-amino-4,5-dichlorothiophene-2-carboxylic acid as a brown solid methyl ester, which was used as such in the next step. LogP=3.11. (M+H)=226.

[0355] Step 2 : Preparation of methyl 3-bromo-4,5-dichlorothiophene-2-car...

preparation Embodiment 2

[0363] Preparation Example 2 : Preparation of N-[(4,5-dibromo-3-methyl-2-thienyl)carbonyl]-valine ethyl ester (Compound I.04)

[0364] To a solution of 154 mg (0.50 mmol) of 4,5-dibromo-3-methylthiophene-2-carboxylic acid and 183 mg (1.00 mmol) of DL-valine ethyl ester hydrochloride dissolved in 3 mL of tetrahydrofuran was added 0.21 mL (1.51 mmol) of triethylamine followed by the addition of 0.45 mL (0.75 mmol) of a 50% (w / w) solution of propanephosphonic anhydride in ethyl acetate. The reaction mixture was stirred at room temperature for 2 hours. The reaction mixture was quenched with saturated aqueous sodium bicarbonate solution and extracted with ethyl acetate. The combined organic layers were dried over magnesium sulfate, filtered and concentrated under reduced pressure. The residue was purified by silica gel column chromatography (gradient n-heptane / ethyl acetate) to give 103 mg (95% purity, 45% yield) of N-[(4,5-dibromo-3-methyl) as a white solid -2-Thienyl)carbony...

preparation Embodiment 3

[0365] Preparation Example 3 : Preparation of N-[(4,5-dibromo-3-methyl-2-thienyl)carbonyl]-valine (Compound I.07)

[0366] To a solution of 164 mg (0.38 mmol) of N-[(4,5-dibromo-3-methyl-2-thienyl)carbonyl]-valine ethyl ester in 3 mL of tetrahydrofuran was added dropwise 0.81 mL of 1 M hydrogen Lithium oxide solution (0.81 mmol). The reaction was stirred at room temperature for 18 hours. The reaction mixture was diluted with ethyl acetate and saturated aqueous sodium bicarbonate. The organic layer was washed twice with saturated aqueous sodium bicarbonate solution. The combined aqueous layers were carefully acidified with 37% (w / w) aqueous hydrochloric acid at 0°C and extracted with ethyl acetate. The combined organic layers were dried over magnesium sulfate, filtered and concentrated under reduced pressure to give 151 mg (98% purity, 96% yield) of N-[(4,5-dibromo-3-methyl) as a white solid -2-Thienyl)carbonyl]-valine. LogP=2.92. (M+H)=398.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com