Purification and noise elimination integrated engine catalytic converter based on negative poisson ratio metamaterial

A catalytic converter, negative Poisson's ratio technology, applied in the direction of engine components, machines/engines, mufflers, etc., can solve the problems of short service life of the carrier, poor muffling performance, low catalyst utilization efficiency, etc., to prolong the service life. , reduce thermal stress, improve the effect of catalytic conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

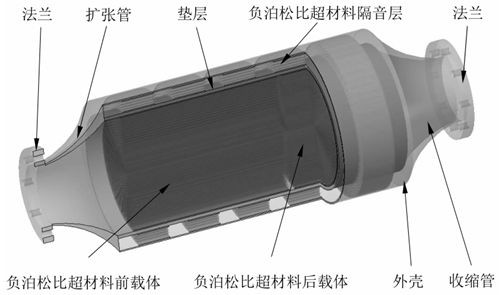

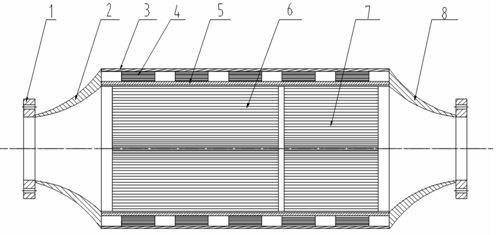

[0031] like figure 1 and image 3 As shown, an engine catalytic converter based on a negative Poisson’s ratio metamaterial that integrates purification and noise reduction consists of a flange 1, an expansion tube 2, a casing 3, a cushion 5, and a negative Poisson’s ratio metamaterial sound insulation layer 4 , a negative Poisson’s ratio metamaterial front carrier 6, a negative Poisson’s ratio metamaterial back carrier 7 and a shrink tube 8; It is connected with one end of the shell 3, and the other end of the shell 3 is connected with the inlet end of the shrink tube 8. The negative Poisson's ratio metamaterial sound insulation layer 4 is installed between the shell 3 and the cushion 5 , and the negative Poisson's ratio metamaterial front carrier 6 and the negative Poisson's ratio metamaterial rear carrier 7 are installed inside the cushion 5 .

[0032] The expansion tube 1 and the contraction tube 8 are smooth and streamlined curved surfaces to reduce flow resistance.

[...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap