System and method for treating biogas produced by co-fermentation of livestock and poultry breeding wastes

A technology for livestock and poultry breeding and treatment system, which is applied in the field of co-fermentation of livestock and poultry wastes to produce biogas treatment system, can solve the problems of paralysis, long fermentation period, inhibition of fermentation gas production, etc., and achieves low cost, shortened fermentation period, and improved The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

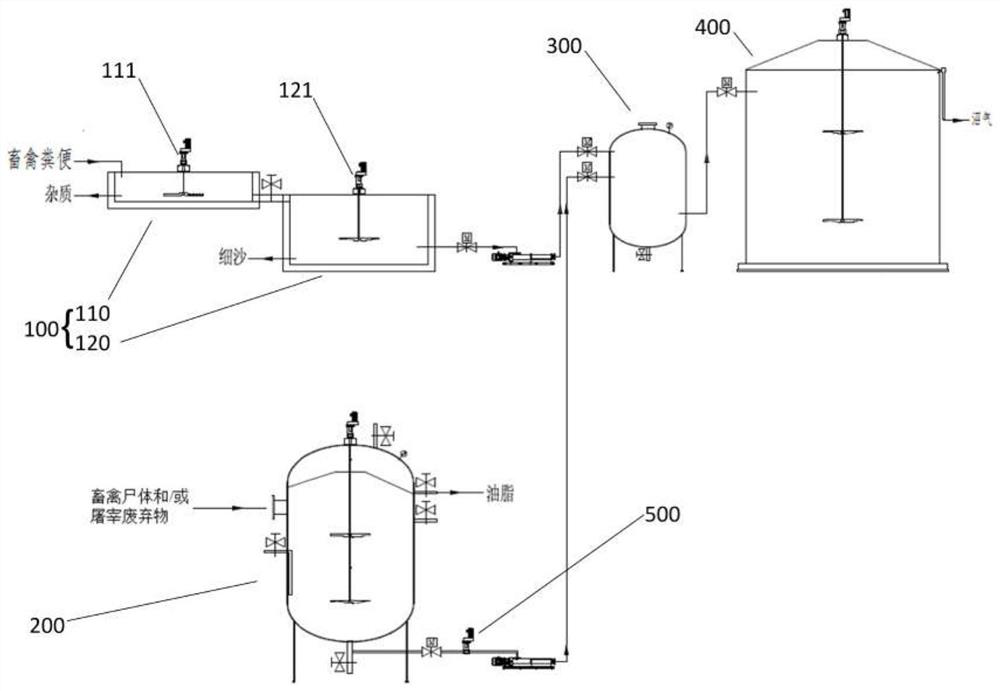

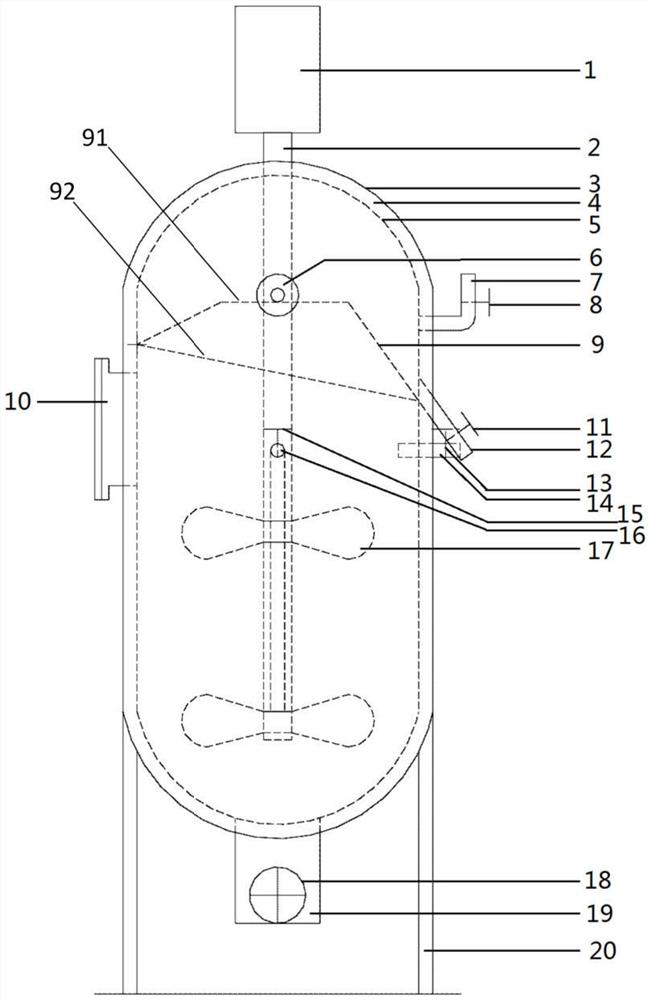

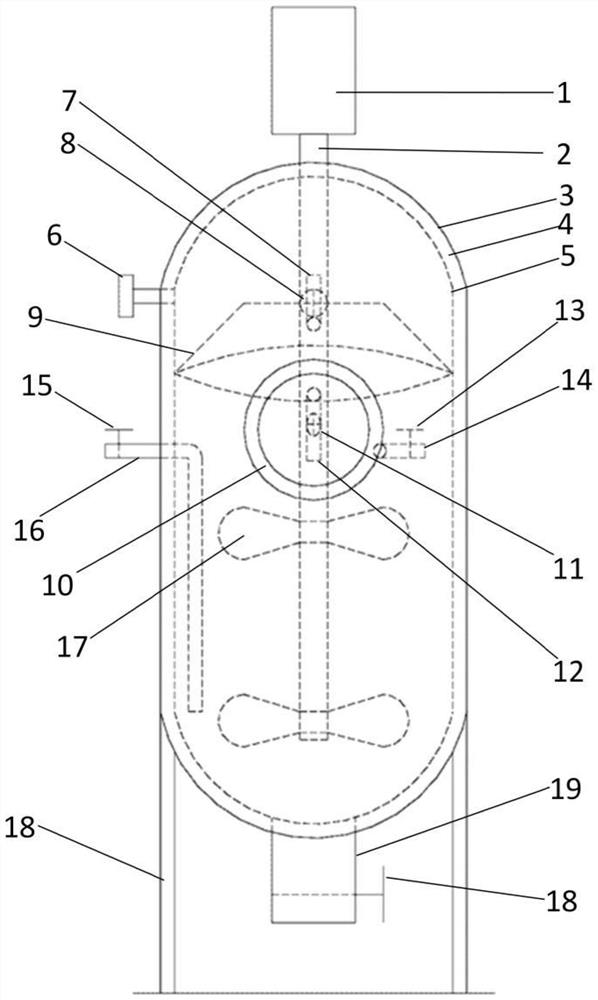

[0038] Example 1 Livestock and poultry breeding waste co-fermentation biogas treatment system

[0039] figure 1 It is a schematic diagram of the overall structure of the livestock and poultry waste co-fermentation biogas treatment system in this embodiment, including a livestock and poultry manure pretreatment device 100, a harmless treatment device 200 and an anaerobic fermentation device 400, wherein the livestock and poultry manure pretreatment The treatment device 100 and the harmless treatment device 200 are respectively connected to the anaerobic fermentation device 400 through pipelines; the livestock and poultry manure pretreatment device 100 pretreats the livestock and poultry manure to be treated before fermentation, and the pretreated livestock and poultry manure The poultry manure material is output to the anaerobic fermentation device 400; the harmless treatment device 200 performs high-temperature sterilization and grease separation on the livestock and poultry c...

Embodiment 2

[0067] Embodiment 2 Livestock and poultry breeding waste co-fermentation produces biogas processing method

[0068] Figure 4 It is a schematic flow chart of the method for co-fermenting biogas from livestock and poultry breeding waste in this embodiment, as shown in Figure 4 As shown, the livestock and poultry breeding waste co-fermentation biogas treatment method in this embodiment includes:

[0069] S10, pretreatment of livestock and poultry manure to be treated: feed the to-be-treated livestock and poultry manure to the livestock and poultry manure pretreatment device for pretreatment, and obtain pretreated livestock and poultry manure material;

[0070] S20. Harmless treatment of untreated livestock and poultry carcasses and / or slaughter wastes: Feed the untreated livestock and poultry carcasses and / or slaughter wastes into a harmless treatment device for high-temperature sterilization and grease separation to remove grease, and obtain Harmless materials;

[0071] S30...

Embodiment 3

[0085] Example 3 Sick and dead chickens and slaughter waste harmless treatment and its anaerobic fermentation gas production potential determination test

[0086] In this embodiment, the harmless treatment device in Embodiment 1 is used, and the sick and dead chickens and slaughter wastes of the chicken farm are used as raw materials for harmless treatment. The specific steps are as follows:

[0087] Firstly, put dead chicken carcasses and slaughter waste into the treatment tank, and put steam into the tank, and the temperature in the tank is 110°C-150°C; start stirring at the same time, and stop stirring after 1-3 hours of high-temperature treatment. Then open the exhaust valve to balance the pressure inside and outside the tank, then start to fill the tank with water, and stop the water intake when liquid flows out of the oil discharge pipe. Then start stirring to make the material and water fully contact and mix, then stop stirring, let stand for treatment, grease and water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com