Selective thermal sintering molding 3D printing mercury removal bag cage and preparation method thereof

A 3D printing and thermal sintering technology, applied in the direction of separation methods, chemical instruments and methods, 3D object support structures, etc., can solve the problem of poor fastness of uniform combination of catalysts, affect the actual application effect of mercury removal filter bags, and catalyst loading capacity Small and other problems, to achieve the effect of large load, improve the effect of granulation and extrusion, and avoid hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

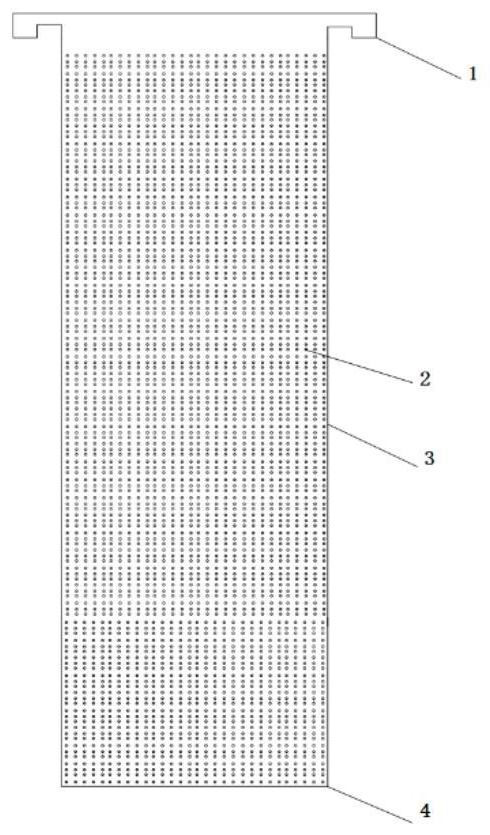

[0032] refer to figure 1 , figure 2 and image 3 , a selective thermal sintering molding 3D printing mercury removal bag cage and a preparation method thereof, comprising the following steps:

[0033] (1) By weight, 30-55 parts of mercury removal catalyst powder, 20-45 parts of polytetrafluoroethylene powder, 10-20 parts of polyimide powder, 0.5-4 parts of didodecyl alcohol ester, 5- 10 parts of nano-silica are mixed, ball milled, and then melted to obtain the material, and then 0.2 to 4 parts of dioctyl phthalate are added to the material, stirred, extruded and granulated to obtain 3D printing printing materials;

[0034] (2) Create a three-dimensional model of the mercury removal bag cage. The main body of the mercury removal bag cage is a straight cylinder with micropores, and the bottom of the straight cylinder is also provided with micropores, and the size and spacing of the micropores are set;

[0035] (3) slice the three-dimensional model of the mercury removal bag...

Embodiment 1

[0048] After mixing 6.2kg of mercury removal catalyst powder, 5.4kg of polytetrafluoroethylene powder, 2.8kg of polyimide powder, 0.4kg of dodecyl alcohol ester, and 1kg of nano silicon dioxide, they were placed on a planetary ball mill for ball milling. The speed of the ball mill is 220r / min, every 20min is a round, and there are 5 rounds of grinding, that is, the ball milling time is 100min. Then melt processing at 380°C to obtain material A, then add 0.045kg of dioctyl phthalate to the material A, stir to obtain material B, and then extrude powder particles with an average particle size of 30 μm through a granulator, Obtain printing materials that can be used by 3D printing equipment; use Solidworks software to create a 3D model of the bag cage. The size of the bag cage is: the diameter of the upper ring mouth is 155mm, the thickness is 5mm, the bottom diameter is 120mm, the length of the bag cage is 900mm, and the diameter of the microhole is 3mm , Microhole spacing 5mm. ...

Embodiment 2

[0052] After mixing 7.6kg of mercury removal catalyst powder, 5.1kg of polytetrafluoroethylene powder, 2.5kg of polyimide powder, 0.3kg of dodecyl alcohol ester, and 1.2kg of nano-silicon dioxide, they are placed on a planetary ball mill for ball milling , the speed of the ball mill is 220r / min, every 20min is a round, and there are 5 rounds of grinding, that is, the ball milling time is 100min. Then melt processing at 380°C to obtain material A, then add 0.085kg dioctyl phthalate to the material A, stir to obtain material B, and then extrude powder particles with an average particle size of 40 μm through a granulator, Get printing materials that can be used by 3D printing equipment; use Solidworks software to create a 3D model of the bag cage. The size of the bag cage is: the diameter of the upper ring mouth is 155mm, the thickness is 5mm, the bottom diameter is 120mm, the length of the bag cage is 900mm, and the diameter of the microhole is 5mm , Microhole spacing 5mm. Use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com