Straw mixing equipment for processing rice straw decoration plate

A technology for rice straw and mixing equipment, which is applied in the direction of mixers, wood processing appliances, mixers with rotating containers, etc., and can solve the problems of uneven and insufficient mixing of straw materials, poor mixing effect of straw materials, and affecting processing procedures, etc. , to achieve the effect of improving the stirring and mixing effect, not easily damaged and deformed, and reducing the rotational resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

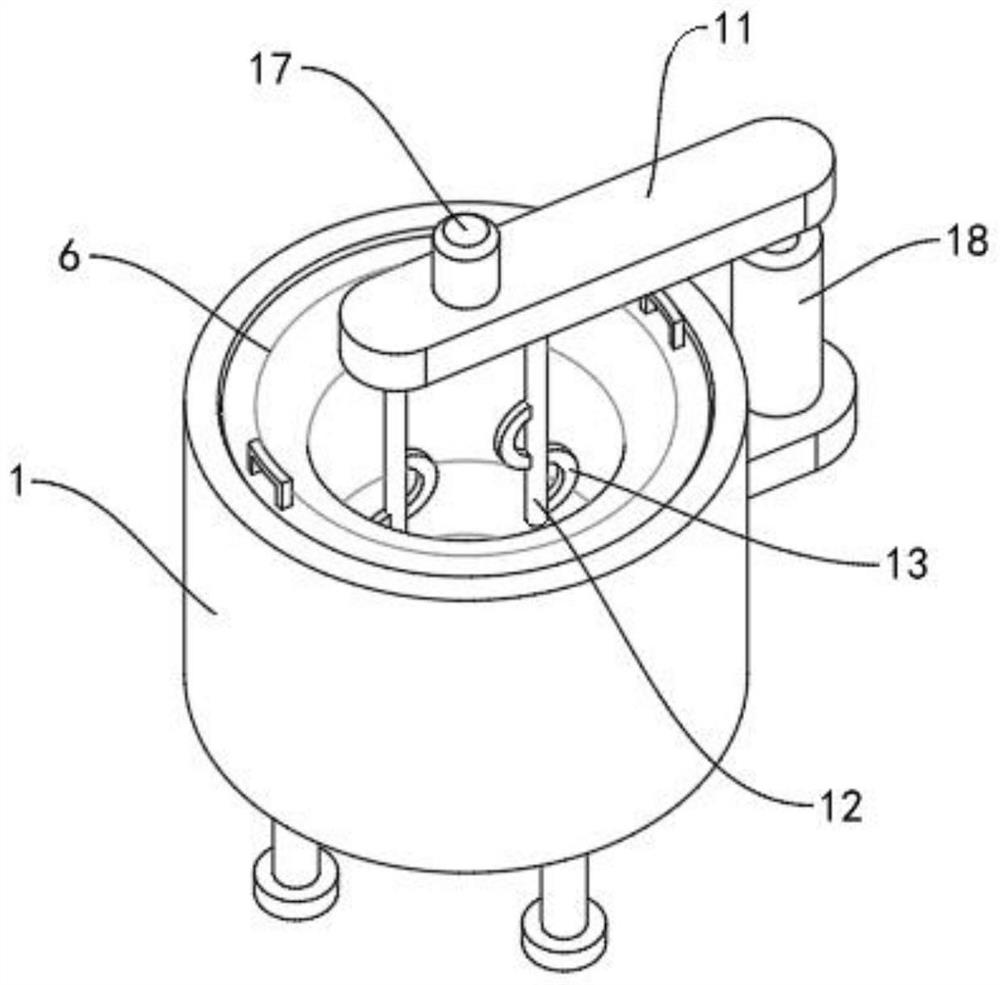

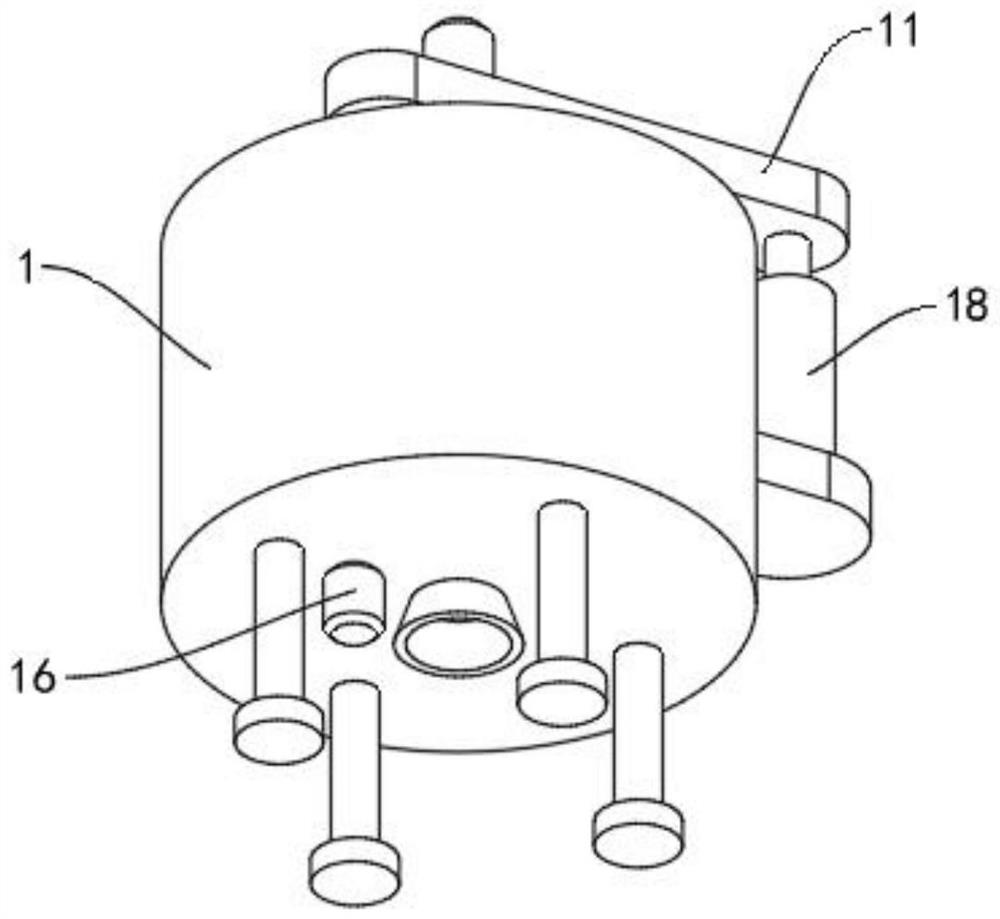

[0031] Refer to the accompanying drawings below Figure 1-Figure 6 A straw mixing device for processing rice straw decorative boards according to Embodiment 1 of the present invention is described. The device includes an outer cylinder 1 , an inner cylinder 6 , a first driving mechanism and a stirring seat 11 .

[0032] like figure 1 and Figure 4 As shown, the outer cylinder 1 defines a placement chamber 2 with an open upper end, a support portion 3 is provided on the inner peripheral wall of the installation chamber, and a rotatable ball 4 is embedded on the upper surface of the support portion 3, and a penetrating outer wall is provided on the bottom wall of the installation chamber. The first discharge hole 5 of the barrel 1.

[0033] like figure 1 and Image 6 As shown, the inner cylinder 6 defines a stirring chamber 7 with an open upper end, and the outer peripheral wall of the inner cylinder 6 is provided with a flanging 8, and the flanging 8 extends in a ring along...

Embodiment 2

[0043] Embodiment 2 is a further improvement to Embodiment 1.

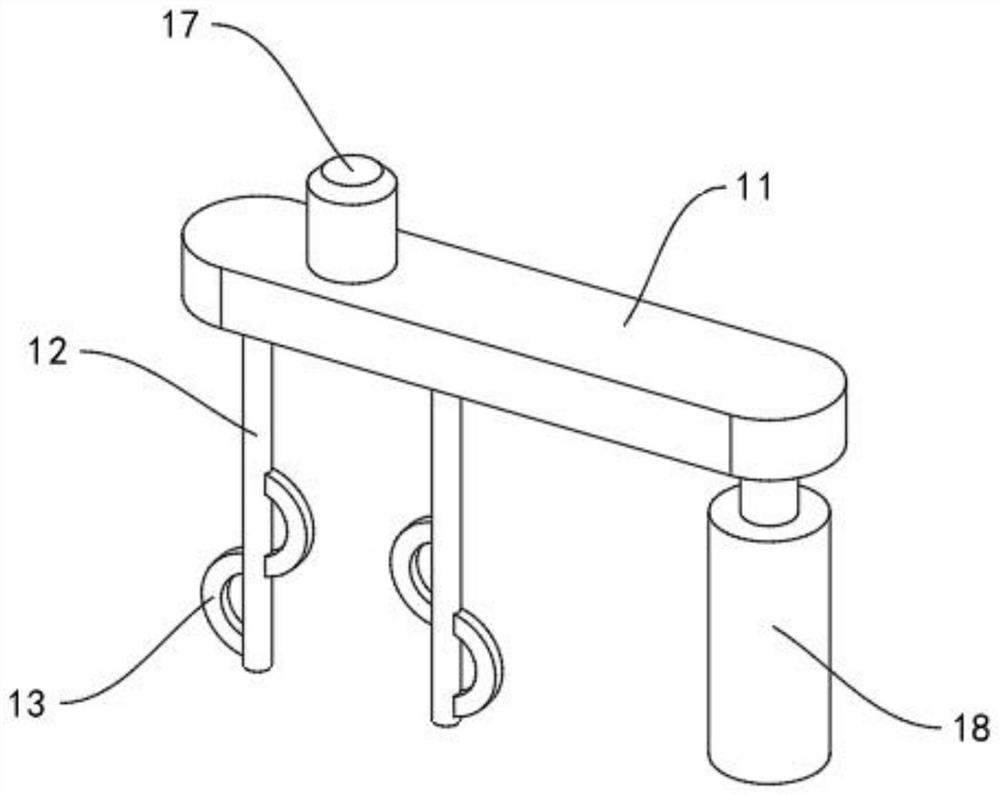

[0044] In this example, if Image 6 As shown, there are two stirring shafts 12, and the third driving mechanism can simultaneously drive the two stirring shafts 12 to rotate, thereby improving the mixing effect. Specifically, the two stirring shafts 12 are respectively provided with a third gear, and the third drive is a second motor 17, and the second motor 17 is provided with a fourth gear, and the fourth gear meshes with the two third gears simultaneously, thus Simultaneous drive of two stirring shafts 12 can be achieved.

[0045] In this example, if Image 6 As shown, the stirring blade 13 is configured in a semi-circular shape, and both ends of the extending direction of the stirring blade 13 are fixedly connected with the outer peripheral wall of the stirring shaft 12. In this structural form, the stirring blade 13 has high strength and is not easily damaged and deformed.

[0046] In this example, if Im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com