Mixing and defoaming equipment for water paint processing

A technology for water-based paint and equipment, applied in mixers, mixers with rotary stirring devices, dissolving and other directions, can solve problems such as poor mixing and processing effects of paints, and achieve improved processing efficiency, bubble elimination effect, and bubble elimination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

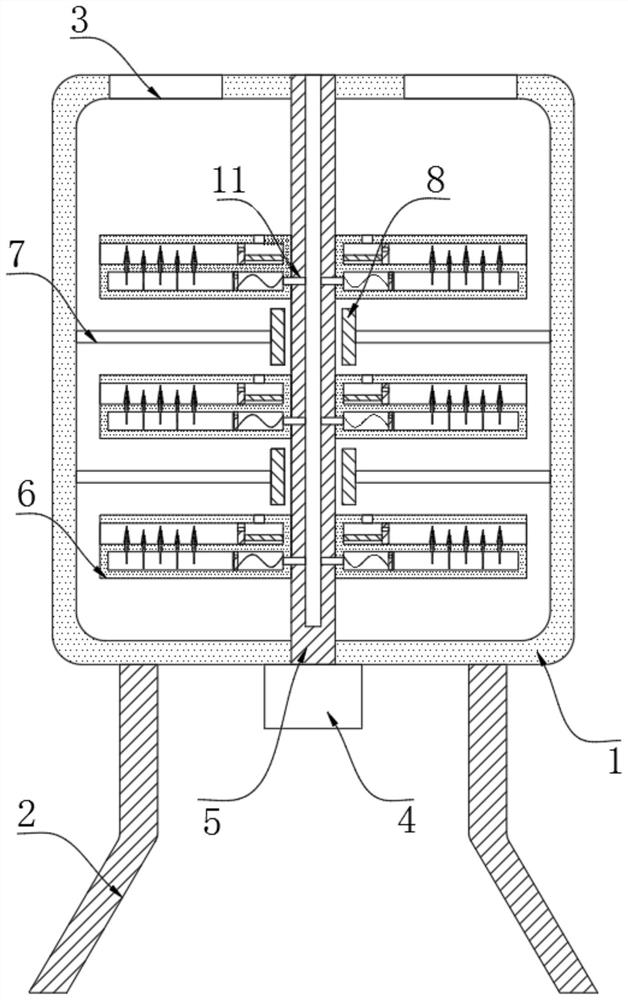

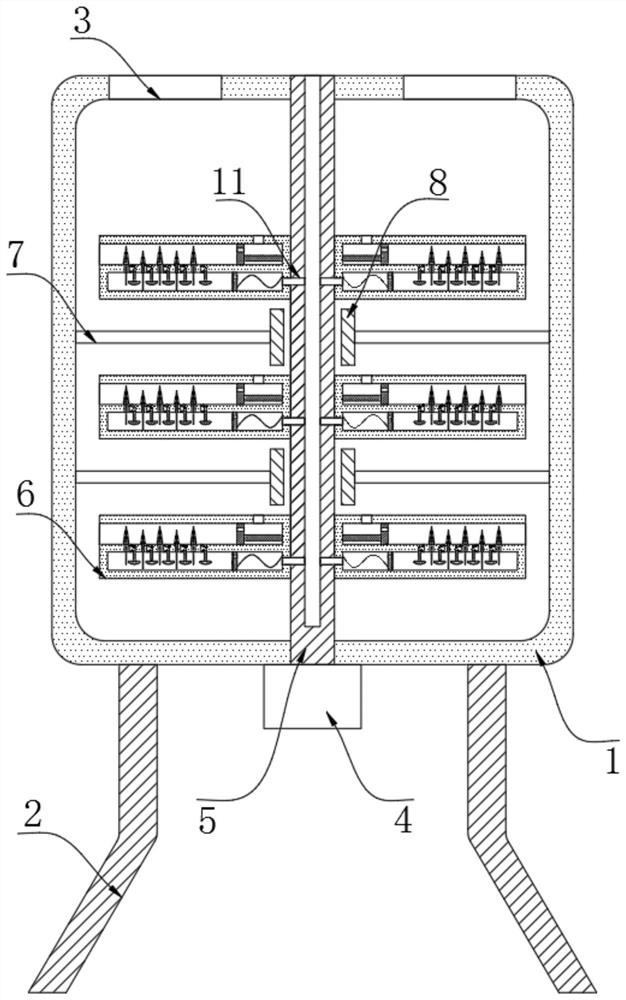

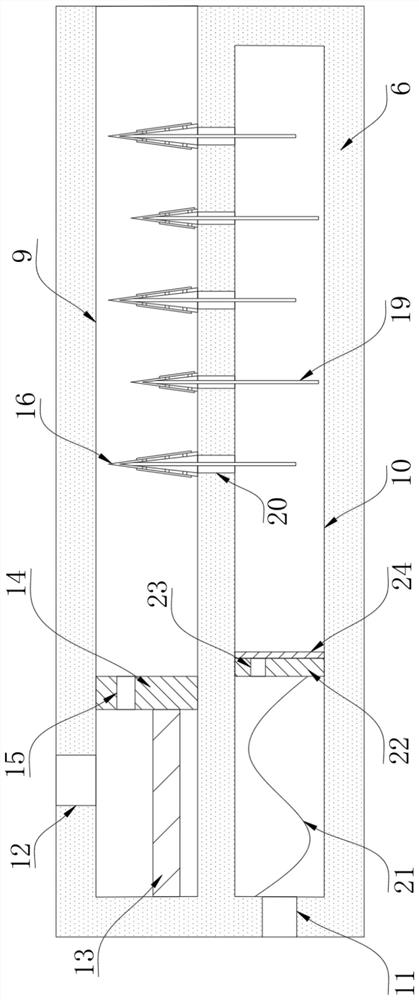

[0023] refer to Figure 1-5 , a mixing and defoaming equipment for water-based paint processing, comprising a stirring box 1, a bracket 2 is fixed on the bottom of the stirring box 1, a discharge port 3 is provided on the upper end of the stirring box 1, a motor 4 is fixed on the bottom of the stirring box 1, and a motor 4 is fixed on the bottom of the stirring box 1. The output shaft of 4 is fixed with a rotating shaft 5, a plurality of stirring blades 6 are fixed on the circumferential side wall of the rotating shaft 5, a plurality of fixed rods 7 are fixed on the inner wall of the stirring box 1, and a magnetic block is fixed at the end of each fixed rod 7 8. The magnetic block 8 is a permanent magnet. The side wall of the stirring blade 6 is provided with a defoaming tank 9. The inside of the defoaming tank 9 is provided with a defoaming mechanism. The inside of the stirring blade 6 is provided with an exhaust chamber 10. The exhaust chamber 10 There is an exhaust mechanis...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that an air extraction strengthening mechanism is added. The interior of the exhaust chamber 10 is provided with multiple sets of air extraction strengthening mechanisms. The inwall of groove 25 is connected with slide bar 27 by compression spring 26, and the end portion of slide bar 27 is fixed with differential pressure plate 28, and the side wall of slide bar 27 runs through and is provided with discharge hole 29, and the inwall of discharge hole 29 and chute 25 are both A one-way valve is provided, and the sliding rod 27 is sealed and slidingly connected with the inner wall of the chute 25. The inside of the chute 25 is provided with a ventilating liquid barrier film. One side of the pressure difference plate 28 is an arc surface and the other side is a plane. create a pressure difference;

[0032]During the movement of the magnetic fluid, it will quickly pass through the pressure difference plate 28, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com