A kind of rotating and striking walnut shell breaking equipment

A shell breaking equipment and a striking technology, which are applied in the field of rotary striking walnut shell breaking equipment, can solve the problems of poor practicability, troublesome kernel removal, high use and maintenance costs, and save the use and maintenance costs of the device. , Shell breaking efficiency guarantee, reducing the effect of hitting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

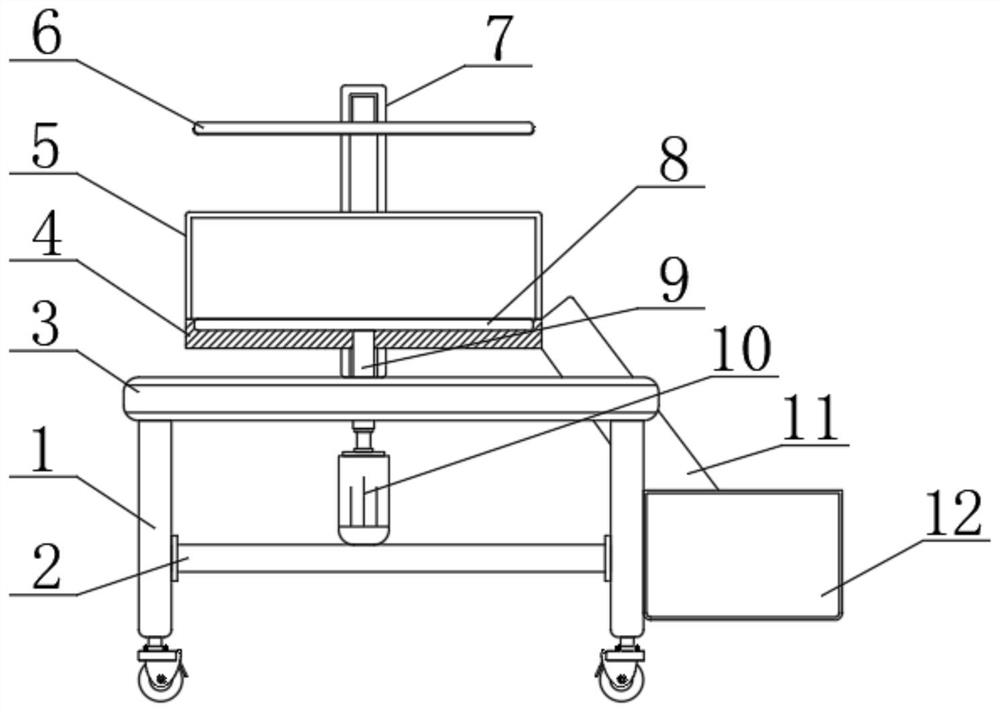

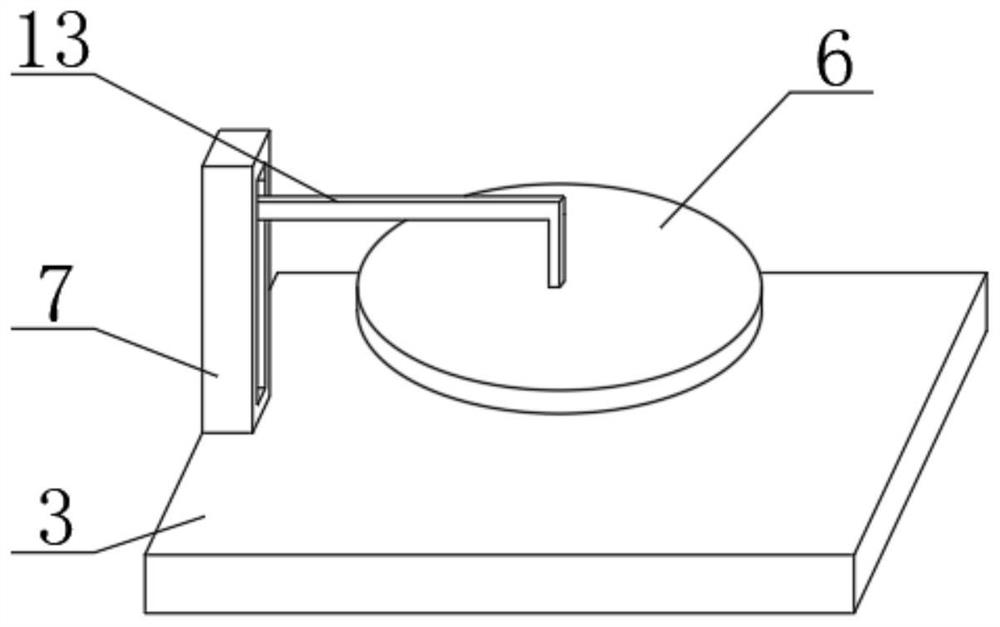

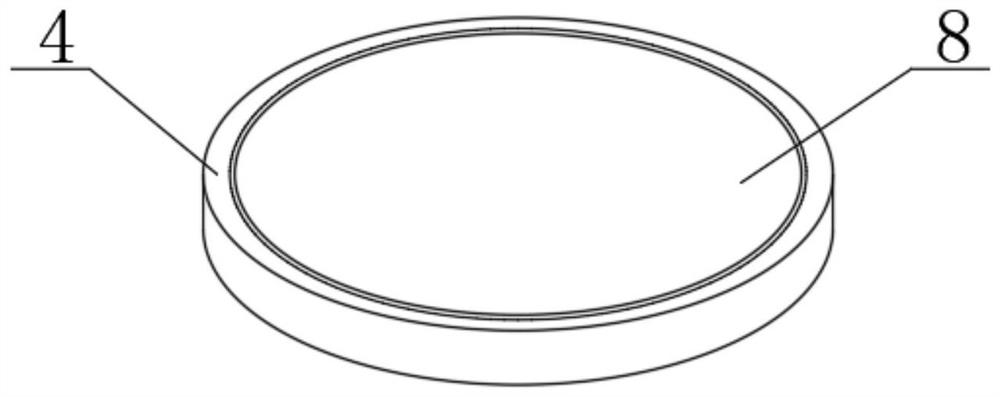

[0023] see Figure 1-5 , the present invention provides the following technical solutions: a rotary impact walnut shell breaking equipment, comprising a support plate 3, the four corner positions of the lower surface of the support plate 3 are welded with support columns 1, and one side of the upper surface of the support plate 3 is provided with a The No. 1 circular support plate 4, the No. 2 circular support plate 8 is rotatably connected to the inner side of the No. 1 circular support plate 4, and the limit baffle 5 is welded on the outer surface of the No. 1 circular support plate 4. A No. 1 support block 7 is welded on the surface side, a No. 3 support block 13 is snap-connected on the inner side of the No. 1 support block 7, and a circular striking plate 6 is welded on one end of the outer surface of the No. 3 support block 13, and the circular striking plate 6 is welded. The lower surface of the beating plate 6 corresponds to the position of the upper surface of the No....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com