Anti-wall-adhering reaction kettle

A technology of reaction kettle and anti-stick wall, which is applied in chemical/physical/physical-chemical stationary reactors, mixers with rotary stirring devices, mixers, etc. Obvious and other problems, to achieve the effect of enhancing the de-sticking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

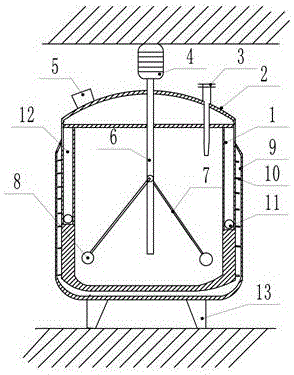

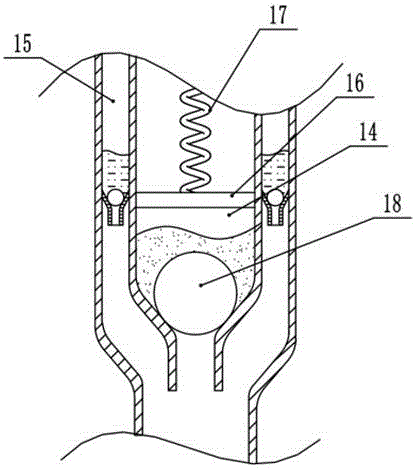

[0021] Embodiment 1 is basically as attached figure 1 And attached image 3 Shown: a reaction kettle with an anti-sticking wall, which is mainly composed of a kettle body 1, a support 13, a stirring unit and a transmission 4. The kettle body 1 is a non-ferrous material, and the non-ferromagnetic material is a material that cannot attract each other with a magnet. The kettle body 1 is composed of a cylinder and a lower head. The outer wall of the cylinder is coiled with slats 10. The barrel and the lower head are surrounded by a U-shaped jacket 9. Both sides of the kettle body 1 are provided with compartments 12, and movable blocks 11 that can be attracted by magnetic substances are placed in the compartments 12. A kettle cover 2 is installed on the upper end of the kettle body 1, and the left end of the kettle cover 2 is provided with a feed port 5, and the right end of the kettle cover 2 is fixed with a thermometer sleeve 3, and the thermometer sleeve 3 runs through the ket...

Embodiment 2

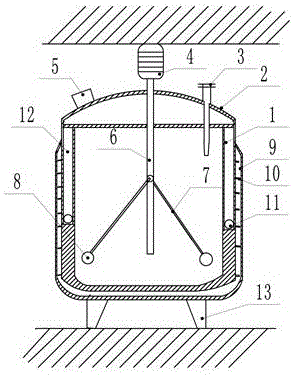

[0024] Embodiment 2 is basically as attached figure 2 Shown:

[0025] The difference between this embodiment and Embodiment 1 is that the inner wall of the kettle body 1 is arranged obliquely and is in the shape of a funnel. When the spherical magnet is attracted by the magnetic force, the spherical magnet is more likely to overcome gravity under the action of the magnetic force and the supporting force, so that it can be faster. It moves more easily and bumps into the inner wall of the compartment to enhance the vibration effect; the inner wall of the compartment 12 is coated with anti-impact material to prevent the spherical magnet from causing damage to the inner wall of the kettle body 1; the movable block 11 that can be attracted by the magnetic material is a spherical magnet. When the spherical magnet hits the inner wall of the compartment 12 due to the magnetic force, the stressed surface of the compartment 12 is smaller and the pressure is greater, and the vibration o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com