Packaging structure, preparation method thereof and photoelectric device

A packaging structure, optoelectronic device technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of poor device stability, water-oxygen isolation effect, poor thermal conductivity, short life, etc., to reduce interface thermal resistance, improve Water and oxygen barrier properties and the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

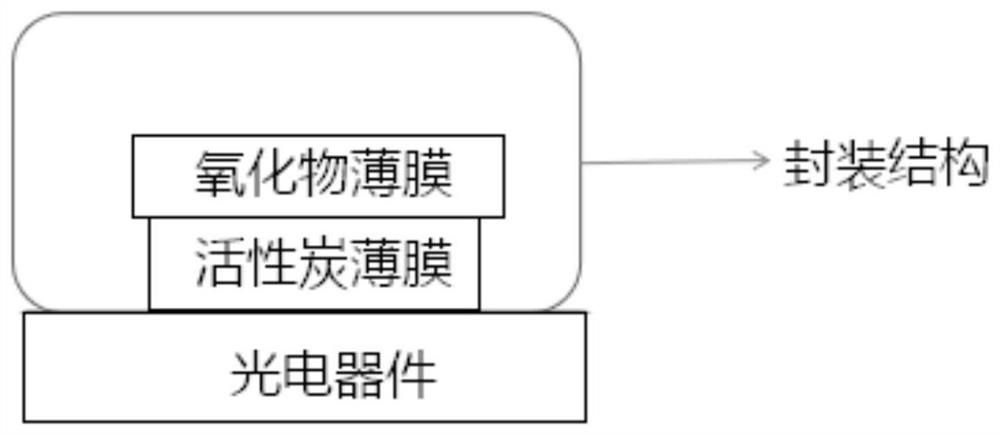

[0051] This embodiment provides an optoelectronic device. The optoelectronic device includes a substrate, a quantum dot light emitting diode combined on the substrate and a package structure for packaging the quantum dot light emitting diode. The structure of the photoelectric device is as follows from bottom to top: ITO substrate (50nm) / PEDOT:PSS (50nm) / poly-TPD (30nm) / quantum dot light-emitting layer (20nm) / ZnO (30nm) / Mg-Ag Alloy (50nm) / package structure (400mm).

[0052] On the ITO substrate, each layer is sequentially formed according to the quantum dot light emitting diode structure of this embodiment, thereby forming a quantum dot light emitting diode;

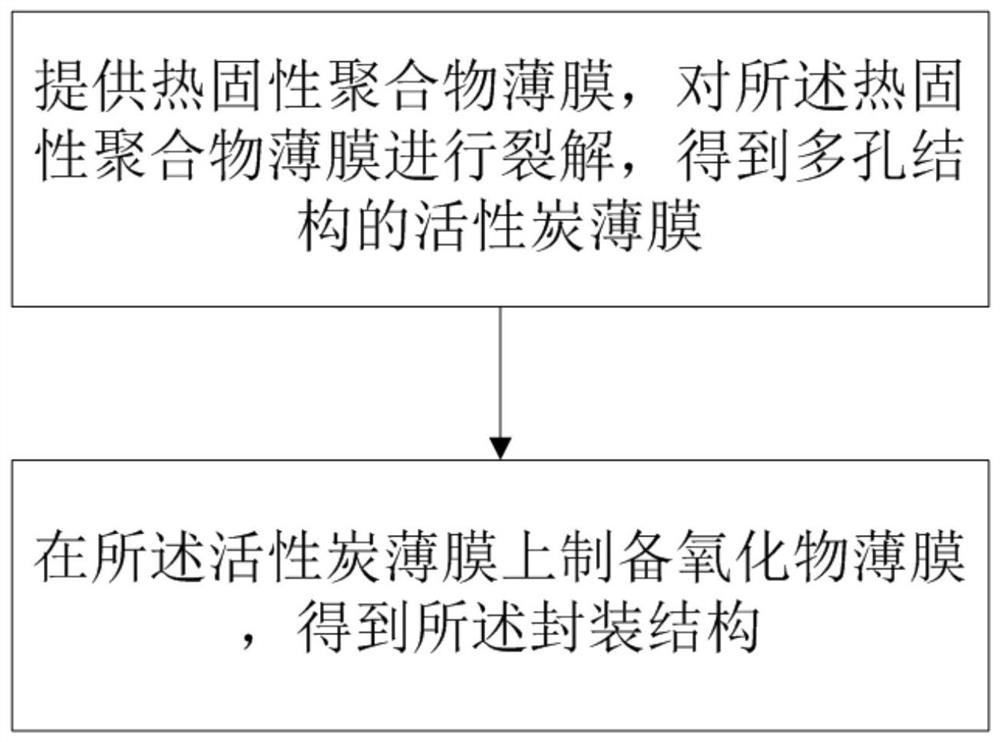

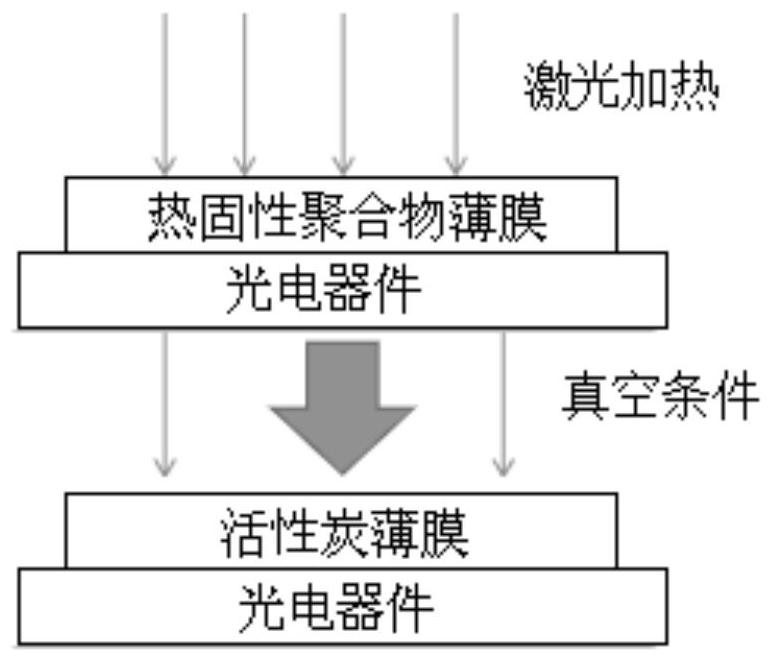

[0053] The encapsulation structure is composed of two layers: a 300nm thick porous activated carbon film, and a 100nm thick silicon dioxide film formed on the porous activated carbon film. The preparation process of the porous activated carbon film is as follows: make polyvinylidene chloride into ink, and then inkjet p...

Embodiment 2

[0056] This embodiment provides an optoelectronic device. The optoelectronic device includes a substrate, a quantum dot light emitting diode combined on the substrate and a package structure for packaging the quantum dot light emitting diode. The structure of the photoelectric device is as follows from bottom to top: ITO substrate (50nm) / PEDOT:PSS (50nm) / poly-TPD (30nm) / quantum dot light-emitting layer (20nm) / ZnO (30nm) / Mg-Ag Alloy (50nm) / package structure (600mm).

[0057] On the ITO substrate, each layer is sequentially formed according to the quantum dot light emitting diode structure of this embodiment, thereby forming a quantum dot light emitting diode;

[0058]The encapsulation structure is composed of two layers: a 300nm thick porous activated carbon film, and a 100nm thick silicon dioxide film formed on the porous activated carbon film. The preparation process of the porous activated carbon film is as follows: make polyacrylonitrile into ink, and then inkjet print it...

Embodiment 3

[0061] This embodiment provides an optoelectronic device. The optoelectronic device includes a substrate, a quantum dot light emitting diode combined on the substrate and a package structure for packaging the quantum dot light emitting diode. The structure of the photoelectric device is as follows from bottom to top: ITO substrate (50nm) / PEDOT:PSS (50nm) / poly-TPD (30nm) / quantum dot light-emitting layer (20nm) / ZnO (30nm) / Mg-Ag Alloy (50nm) / package structure (400mm).

[0062] On the ITO substrate, each layer is sequentially formed according to the quantum dot light emitting diode structure of this embodiment, thereby forming a quantum dot light emitting diode;

[0063] The encapsulation structure consists of two layers: a 300nm thick porous activated carbon film, and a 100nm thick titanium dioxide film formed on the porous activated carbon film. The preparation process of the porous activated carbon film is as follows: polyvinylidene chloride compound Ink, then inkjet printing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com