Electromagnetic clutch

An electromagnetic clutch and mating technology, applied in the field of clutches, can solve the problems of high cost, large external size, poor heat dissipation, etc., and achieve the effects of low cost, convenient installation and operation, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

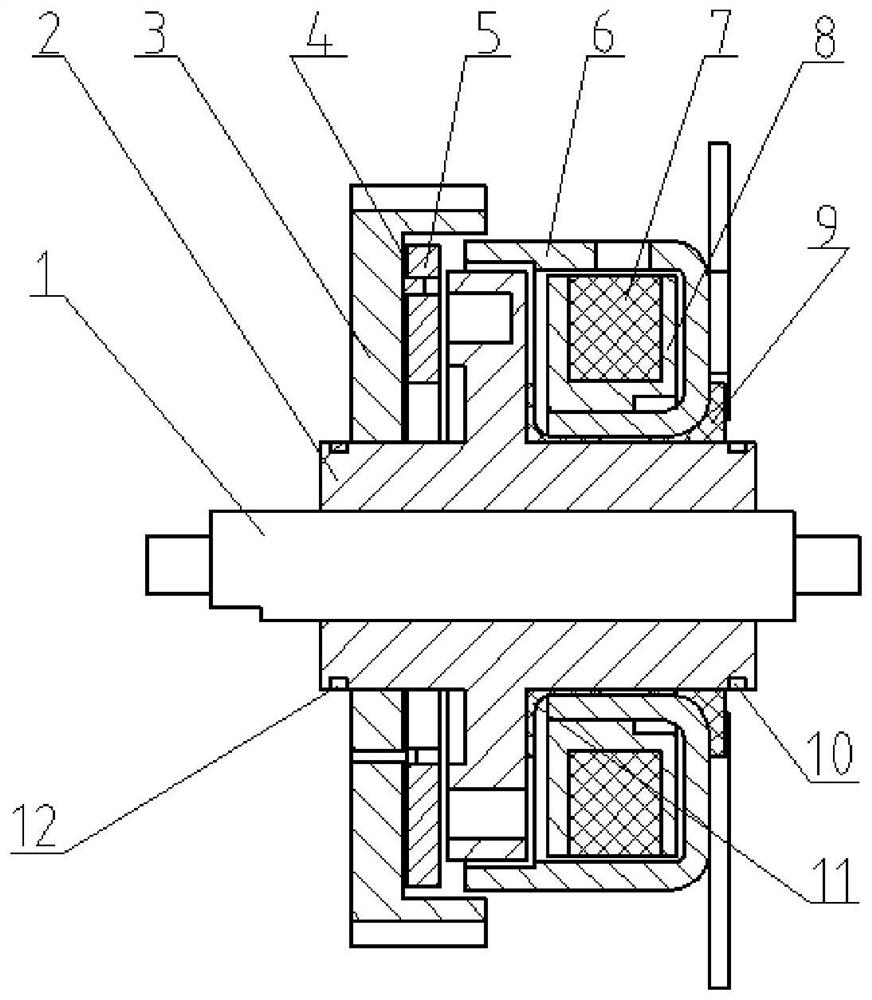

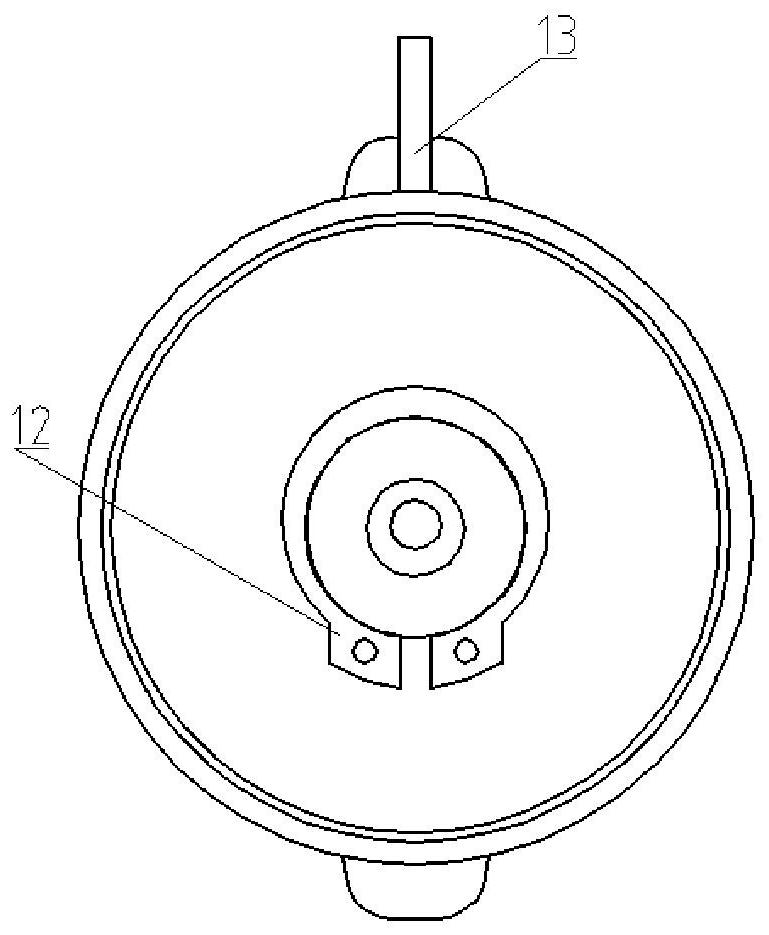

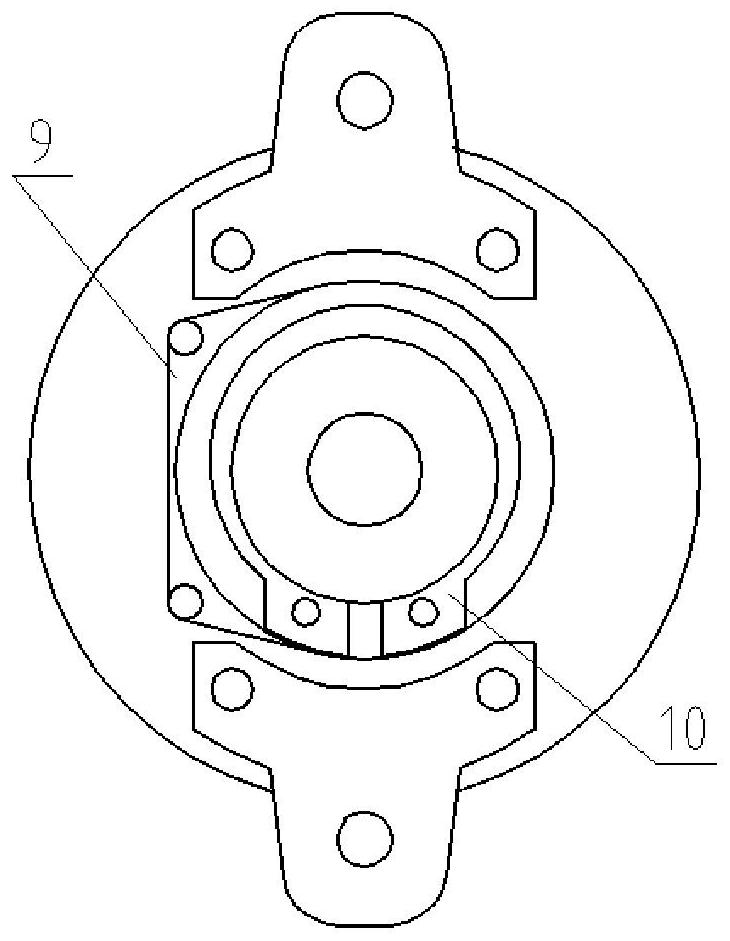

[0028] Such as Figure 1-Figure 6 As shown, an electromagnetic clutch includes a rotating disk 2, an output gear 3, a butterfly spring 4, an armature 5, a housing 6, a coil 7, a first retaining spring 10 and a second retaining spring 12, and the rotating disk 2 includes The hollow shaft 201 and the disc body 202, the disc body 202 is sleeved on the hollow shaft 201, and the disc body 202 and the hollow shaft 201 are integrally formed, and several waists are evenly provided on the upper end surface of the disc body 202 along the circumferential direction. The upper end surface of the disc body 202 is divided into the first friction ring 14 and the second friction ring 15, and an annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com