Methyl tetrahydrophthalic anhydride or tetrahydrophthalic anhydride polymerization method and application of formed polymer

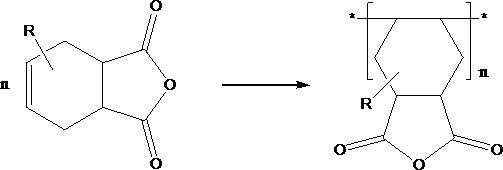

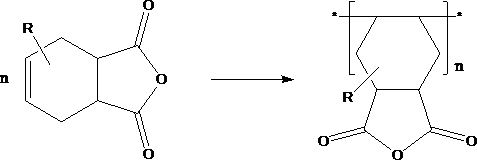

A technology of methyl tetrahydrophthalic anhydride and tetrahydrophthalic anhydride, applied in the direction of organic chemistry, can solve the problems of short lifespan of active species, intramolecular rearrangement, low molecular weight of polymers, etc., and achieve tensile strength and bending strength improvement, comprehensive The effect of good effect and price advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Put 300g of 4-methyltetrahydrophthalic anhydride into a 500ml four-necked flask with a thermometer condenser, heat the oil bath to 100°C, add 2g of initiator benzoyl peroxide, keep it warm for 2 hours, control the temperature not to exceed 150°C, and react After cooling to about 100°C, pour the polymer into a stainless steel container to collect and cool.

[0033] After mixing 100 parts of YD-128 epoxy resin, 70 parts of AMT-120, 30 parts of polymer, and 0.12 parts of N,N-dimethylbenzylamine (BDMA), cure it at 140°C for 10 hours, and measure its tensile strength 79.81Mpa, bending strength 119.34MPa. The TG point is 105.8°C.

Embodiment 2

[0035] Put 300g of 4-methyltetrahydrophthalic anhydride into a 500ml four-neck flask with a thermometer condenser, heat the oil bath to 100°C, add the initiator glycine ferrous complex [(NH 2 CH 2 COO) 2 Fe], 1g of aqueous solution, keep warm for 3 hours, control the temperature not to exceed 170°C, cool to about 100°C after the reaction, pour the polymer into a stainless steel container to collect and cool.

[0036] After mixing 100 parts of YD-128 epoxy resin, 70 parts of AMT-120, 30 parts of polymer, and 0.12 parts of N,N-dimethylbenzylamine (BDMA), it was cured at 140°C for 10 hours, and its bending strength was measured to be 123.43 MPa, tensile strength 81.29MPa. TG point 105.2°C.

Embodiment 3

[0038] Put 300g of 4-methyltetrahydrophthalic anhydride into a 500ml four-neck flask with a thermometer condenser, heat the oil bath to 100°C, add the initiator 30%AlCl 3 4g aqueous solution, keep warm for 4 hours, control the temperature not to exceed 170°C, cool to about 100°C after the reaction, pour the polymer into a stainless steel container to collect and cool.

[0039] After mixing 100 parts of YD-128 epoxy resin, 70 parts of AMT-120, 30 parts of polymer, and 0.12 parts of N,N-dimethylbenzylamine (BDMA), it was cured at 140°C for 10 hours, and its bending strength was measured to be 154.65 MPa, tensile strength 77.86MPa. The TG point is 104.3°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com