Device for inhibiting laser welding deformation

A technology of laser welding and laser welding head, which is applied in the field of devices for suppressing laser welding deformation. It can solve the problems that are not easy to control and cannot effectively improve the deformation effect of thin plate samples, and achieve the effect of controlling welding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

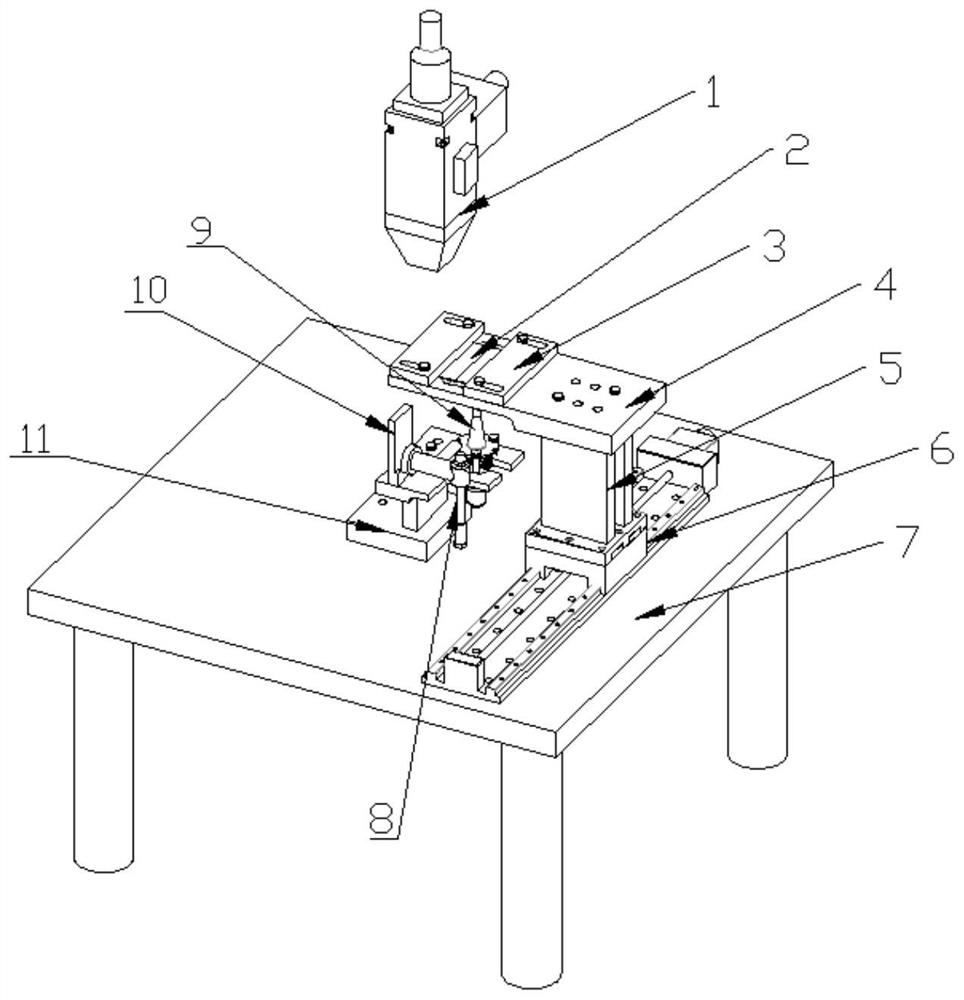

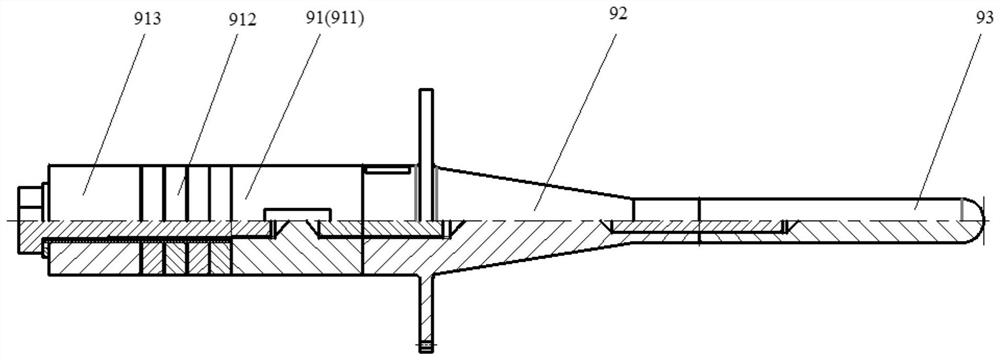

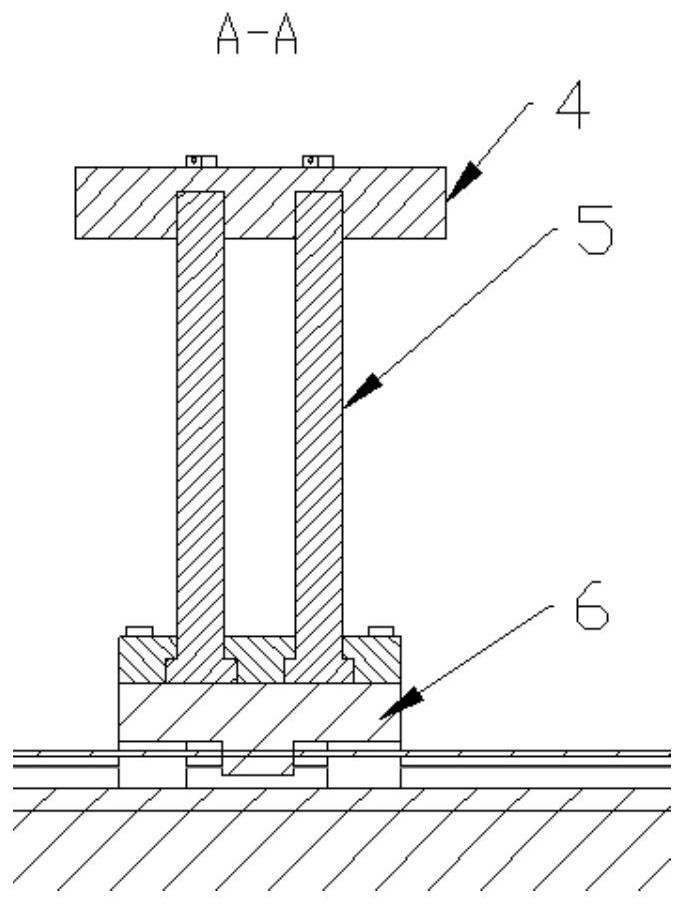

[0035] like Figure 1~5 As shown, the present invention provides a kind of device that suppresses laser welding deformation, and described device comprises welding laser welding head (1), is used for clamping the sample holder (3) of sample to be welded, is used for laser welding A heat sink structure (8) for cooling at the weld seam and an ultrasonic vibration structure (9) for contacting the surface of the sample to be welded, the heat sink structure (8) is a vortex tube for gas refrigeration, and the heat sink The structure (8) comprises a cold air outlet port (81), a hot air outlet port (82), an air inlet port (83) and a fixed end (84), and the cold air outlet port (81) is used for directly or indirectly disabling the air produced by the vortex tube. The cold wind is blown to the weld seam of the sample, and the ultrasonic vibration structure (9) includes a tool head (93), a horn (92) and a transducer (91) sequentially from the head to the tail, and the tool head ( 93) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com