Solid acid alkylation reaction and regeneration device and solid acid alkylation method

A technology of alkylation reaction and regeneration device, which is applied in the direction of chemical instruments and methods, chemical/physical processes, liquid hydrocarbon mixture production, etc., can solve the problems of easy deactivation of solid acid catalysts, and achieve the goal of improving selectivity and device operation Resilience, improvement of economic competitiveness, and effect of improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

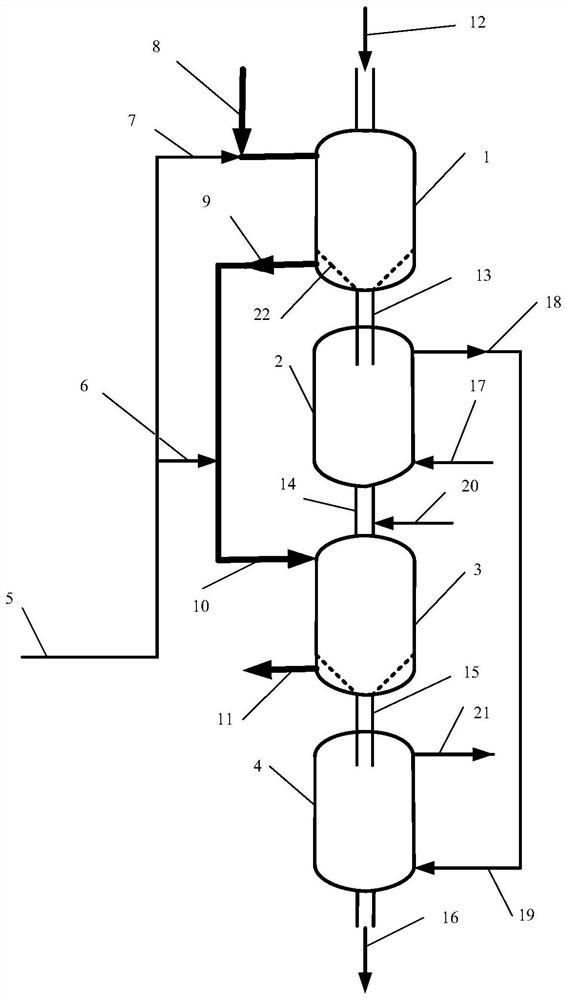

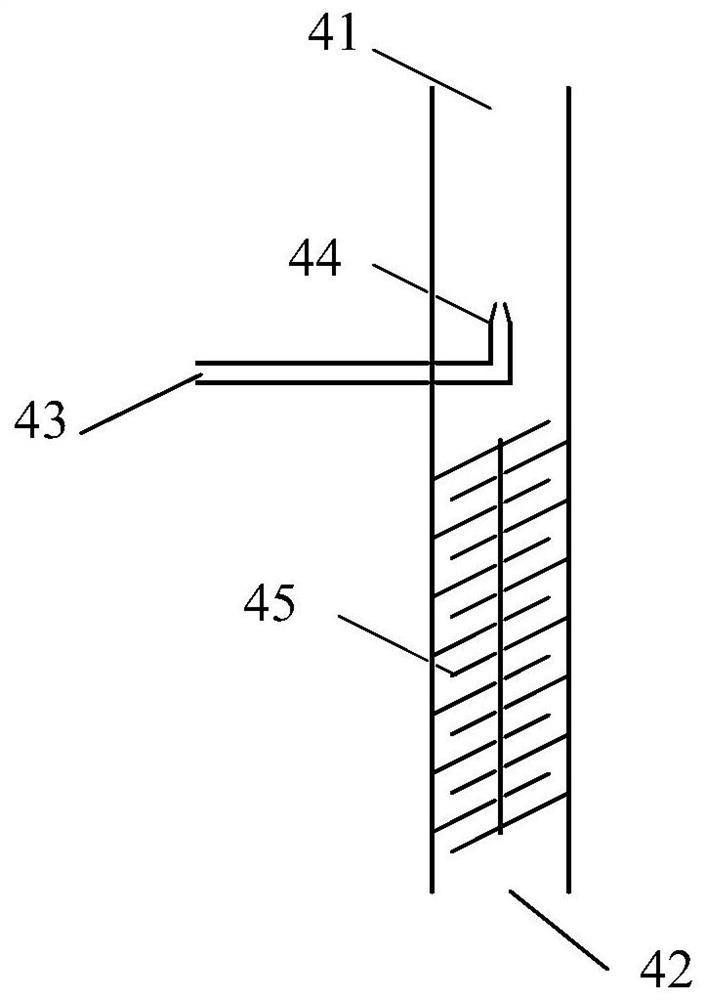

[0052] in the attached figure 1 The solid acid alkylation reaction is carried out on the moving bed experimental device shown. Among them, the inner diameter of the shell of the radial moving bed reactor 1 is 600mm, the height of the reaction bed is 3.5m, the height of the regenerator 2 is 600mm, and the height of the reaction bed is 3.5m; there are three reactors from top to bottom. A reactor and two regenerators, the reactor and the regenerator have basically the same dimensions, and are arranged at intervals in sequence. The regenerated material discharge port on the top of the catalyst regenerator is located at 85% of the straight pipe section of the catalyst regenerator from bottom to top, and the regenerated material inlet is located at 5% of the straight pipe section of the catalyst regenerator from bottom to top. The outlet of the plug-in pipe is located at 80% of the straight pipe section of the catalyst regenerator from bottom to top. The fresh raw material for the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com