Degradable magnesium metal nail for patch fixation and use method

A technology of magnesium metal and metal nails, which is applied in the field of degradable magnesium metal nails, can solve the problems of magnesium metal nails corrosion and shedding, accelerated corrosion rate, and large bending deformation, so as to improve the success rate, reduce damage, and avoid foreign body reactions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

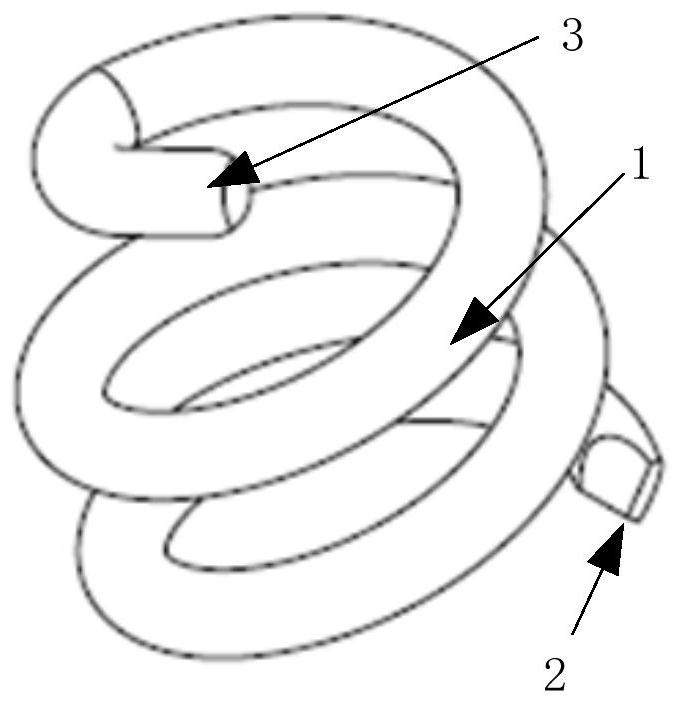

[0050] The present invention provides a degradable magnesium metal nail for patch fixation, comprising a metal nail body 1, the metal nail body 1 is a metal wire wound along a helical direction, and the metal wire is made of pure magnesium, magnesium lithium Any one or more materials in alloys, magnesium-manganese alloys, magnesium-zinc alloys, magnesium-zirconium alloys, magnesium-rare-earth alloys, and magnesium-calcium alloys. The pure magnesium is preferably high-purity magnesium, and its chemical composition should be It meets the requirements of grade Mg9999 in GB / T 3499 Primary Magnesium Ingot. It should be noted that the magnesium alloy used for medical treatment is preferably a ternary, quaternary or even quinary alloy system (element represents the type of alloying element), which should be reasonably selected according to different application scenarios in specific applications.

[0051] Further, the two ends of the metal nail body 1 are a nail head 2 and a nail tai...

Embodiment 2

[0065] This embodiment is a preferred example of Embodiment 1.

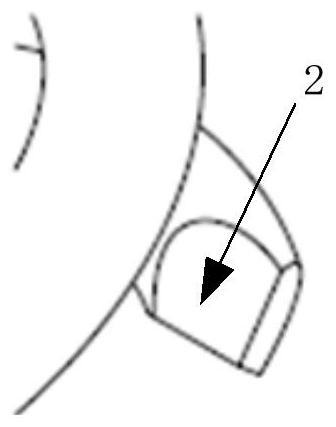

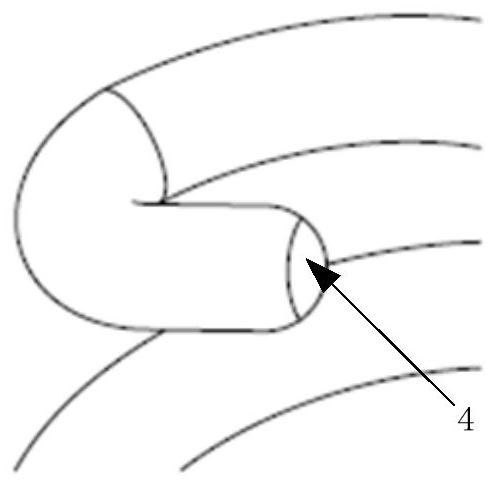

[0066] like figure 1 As shown, a degradable magnesium metal nail for patch fixation is provided in this embodiment. The degradable magnesium metal nail is made of high-purity magnesium (99.99wt.%) wire, and the cross-section of the wire used is a circle with a diameter of 0.95㎜~1.05㎜, the height of the prepared metal nail is 4mm~5㎜, the radial dimension (outer diameter) of the main helical structure is 4mm~5㎜, and the number of spiral turns is 3.5 turns; figure 2 As shown, the nail head 2 of the degradable magnesium metal nail adopts a triangular pyramid design; as image 3 As shown, the nail tail 3 of the degradable magnesium metal nail adopts a hemispherical rounded structure; the manufacturing process of the degradable magnesium metal nail has accumulated 2 times of stress relief annealing, the annealing temperature is 200°C-250°C, and the annealing time is 0-10min .

[0067] Technical effect evaluation: t...

Embodiment 3

[0069] This embodiment is another preferred example of Embodiment 1.

[0070] like Figure 4 As shown, this embodiment provides a degradable magnesium metal nail for patch fixation. The degradable magnesium metal nail is made of Mg-Nd-Zn-Zr alloy wire, and the diameter of the wire used is 0.55mm~ 0.65㎜, the height of the prepared metal nail is 2.7㎜~3.7㎜, the radial dimension (outer diameter) of the main helical structure is 3.5㎜~4.5㎜, and the number of helical turns is 3 turns; Figure 5 As shown, the degradable magnesium metal nail head 2 adopts a triangular pyramid design; Image 6 As shown, the degradable magnesium metal nail tail 3 adopts a bent structure and the free end of the bent structure is a hemispherical structure; the manufacturing process of the degradable magnesium metal nail has accumulated 3 times of stress relief annealing, and the annealing temperature is 250 ℃~300℃, annealing time 0~30min.

[0071] Technical effect evaluation: the tensile strength of the M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com