Selenium-enriched rice bran enzyme deactivation stabilization treatment method

A technology for stabilizing and selenium-enriched rice bran, which is applied in the fields of food heat treatment, food science, food preservation, etc., can solve the problems of low thermal efficiency utilization of rice bran, uneven material temperature, uneven enzyme inactivation effect, etc. Avoid dampening and realize the effect of automatic continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

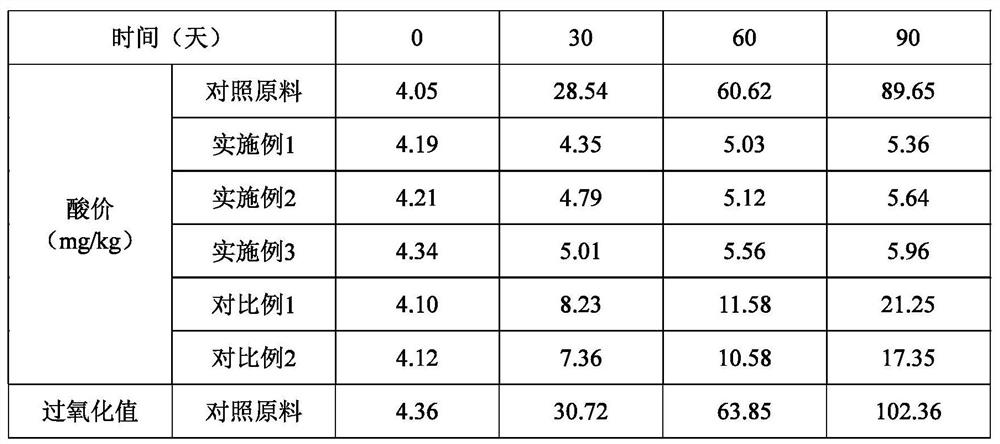

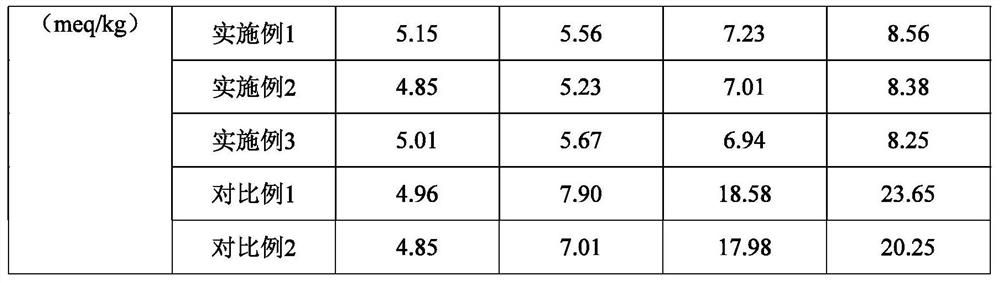

Embodiment 1

[0038]Take fresh rice bran using a three-dimensional vibrating screen screening, and the sieve is obtained. The sieved rice bran 5kg is loaded with high temperature and with a sealing plastic bag, the rice branger is 50% of the plastic bag volume. Seal the self-sealing strip of the plastic bag, leave 4CM outlet. Put the bag of rice branches into the conveyor belt microwave apparatus, paveled the rice bran, the retaining material layer thickness 5cm, turned on the microwave device, the heating temperature of the microwave device was set to 90 ° C, and the heating time was 180 seconds. After the addition of rice bran heating enzymes, the rice bran will be sent to the microwave equipment with the conveyor belt, and the heat is sealed, and then it is sent to the low temperature library to cool, so that the bag rice bran is reduced to 20 ° C.

Embodiment 2

[0040] Take fresh rice bran using a three-dimensional vibrating screen screening, and the sieve is obtained. The sieved rice bran is loaded with high temperature and self-sealing plastic bags, and the rice branger accounted for 60% of the plastic bag volume. Seal the self-sealing strip of the plastic bag, leave 2 cm outlet. Put the bag of rice branches into the conveyor belt microwave apparatus, laying the rice bran in the bag, the retaining material layer thickness is 10 cm, and the microwave device is opened, the heating temperature of the microwave device is set to 85 ° C, and the heating time is 240 seconds. After the addition of rice bran heating enzymes, the rice bran will be sent to the microwave equipment with the conveyor belt, and the heat is sealed, and then it is sent to the low temperature library to cool, so that the bag rice bran is reduced to 20 ° C.

Embodiment 3

[0042] Take fresh rice bran using a three-dimensional vibrating screen screening, and the sieve is obtained. The sieved rice bran is loaded into a plastic bag with high temperatures and self-sealing strips, controls 30% of the plastic bag volume per bag. Seal the self-sealing strip of the plastic bag, leave 2 cm open. Put the bag rice branches into the conveyor belt microwave apparatus, paveled in the bag in the bag, the maintenance layer thickness of 8cm, turned on the microwave device, the heating temperature of the microwave device was set to 60 ° C, and the heating time was 240 seconds. After the addition of rice bran heating enzyme, the conveyor belt sends rice bran to the microwave equipment, seals hot, then feed it into the low temperature library, so that the bag rice bran is reduced to 20 ° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com