Two-dimensional code label scanning error-proofing method

A two-dimensional code label, two-dimensional code technology, applied in the direction of electromagnetic radiation induction, instruments, induction record carriers, etc., can solve problems such as client complaints, untraceable, costly manpower, material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

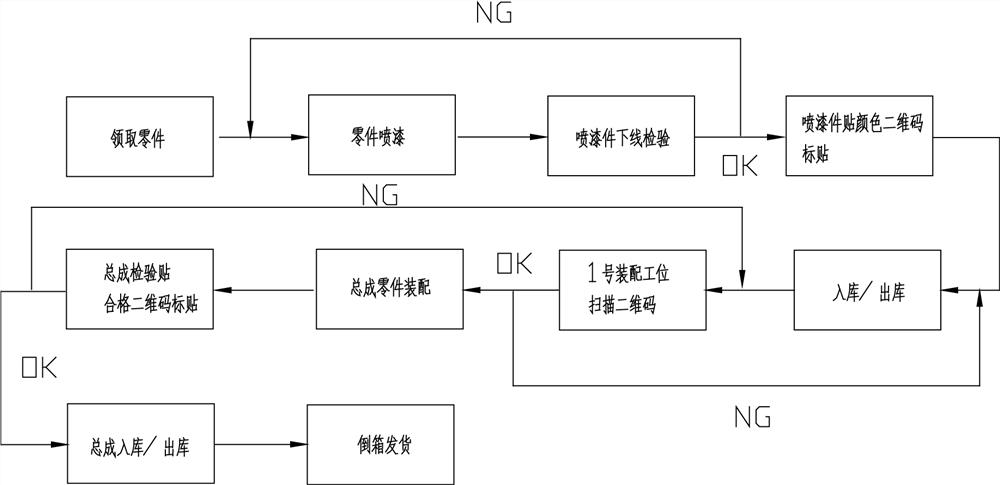

[0016] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 1 , the QR code label scanning code error prevention method includes the following steps: S1) Enter the order configuration into the system according to the order, the order configuration includes different types of spoiler assemblies required, the above spoiler assembly parts and the above spoiler assemblies The paint colors corresponding to the parts of the flow plate assembly;

[0017] S2) Spray the spoiler assembly parts with different colors of paint according to the configuration requirements of the order, and paste the painted spoiler assembly parts with the color QR code label corresponding to the color for later assembly of the parts;

[0018] S3) The first process from painting parts to the assembly line, the operator scans the color QR code label on the part to match the order configuration requirements, and the system c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com