Method for predicting effective elastic modulus of cement paste

A technology of elastic modulus and cement slurry, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of difficult direct measurement, low efficiency of multi-scale models, poor operability, etc., and achieve good compatibility and high degree of agreement , strong operational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The cement slurry mentioned in the examples of the present invention is prepared by mixing ordinary Portland cement with water. The porous structure of the cured cement paste contains gel pores and capillary pores. Pores in cement paste exhibit complex geometric shapes and random spatial distribution.

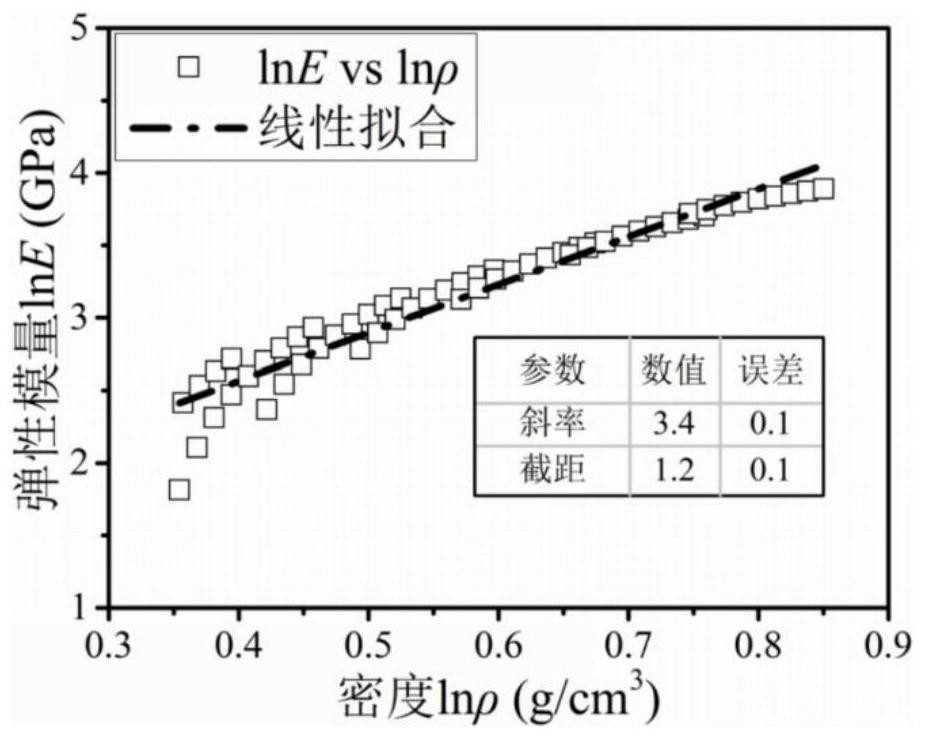

[0053] like Figure 1-5 Shown, the present invention predicts the method for cement slurry effective elastic modulus based on CT image, comprises the steps:

[0054] (1) Cement powder and purified water are mixed according to the mass ratio of 5:2, stirred evenly, poured into a cylindrical mold with a diameter of 40 mm and a height of 160 mm for molding, sent to a standard curing room for curing, demoulded after 24 hours, and sent again The standard curing room is maintained for 28 days.

[0055] (2) Remove the cured test piece from the standard curing room, cut it into small cylindrical test pieces with a diameter of 40 mm and a height of 3 mm, then cool it in a liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com