Efficient industrial boiler pre-combustion chamber

A technology for industrial boilers and pre-combustion chambers, applied in combustion chambers, combustion methods, combustion equipment and other directions, can solve the problems of poor heat recovery effect of pre-combustion chambers, inability to absorb heat energy of pre-combustion chambers, and reduced pre-combustion work efficiency, etc. Achieve high heat exchange efficiency, high work efficiency, and reduce heat exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

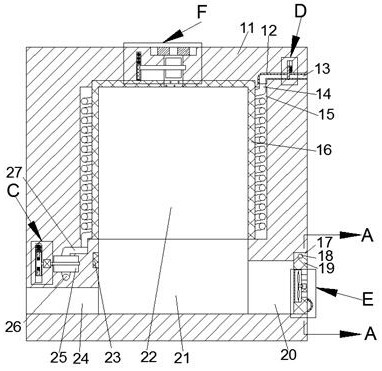

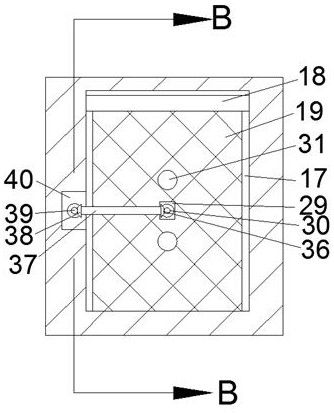

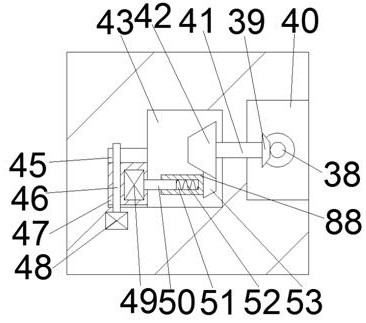

[0024] Combine below Figure 1-9 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0025]A high-efficiency industrial boiler pre-combustion chamber according to the present invention includes a pre-combustion chamber main body 11, a pre-combustion chamber 21 is provided inside the pre-combustion chamber main body 11, and a heat exhausting chamber is connected to the upper side of the pre-combustion chamber 21 cavity 22, the inner wall and upper wall of the heat discharge cavity 22 are fixed with a heat exchange plate 16 made of heat transfer material, and the outer side of the heat discharge cavity 22 is provided with a circular water-cooled heat exchange cavity 15, the water A threaded water cooling pipe 14 is provided in the cold and heat exchange chamber 15, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com